Molecular sieve dehydration method for C-4 fraction

A carbon four fraction and molecular sieve technology, applied in the field of carbon four fraction molecular sieve dehydration, can solve problems such as poor applicability and adverse effects of factories, and achieve the effects of reducing consumption, reducing energy consumption, and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

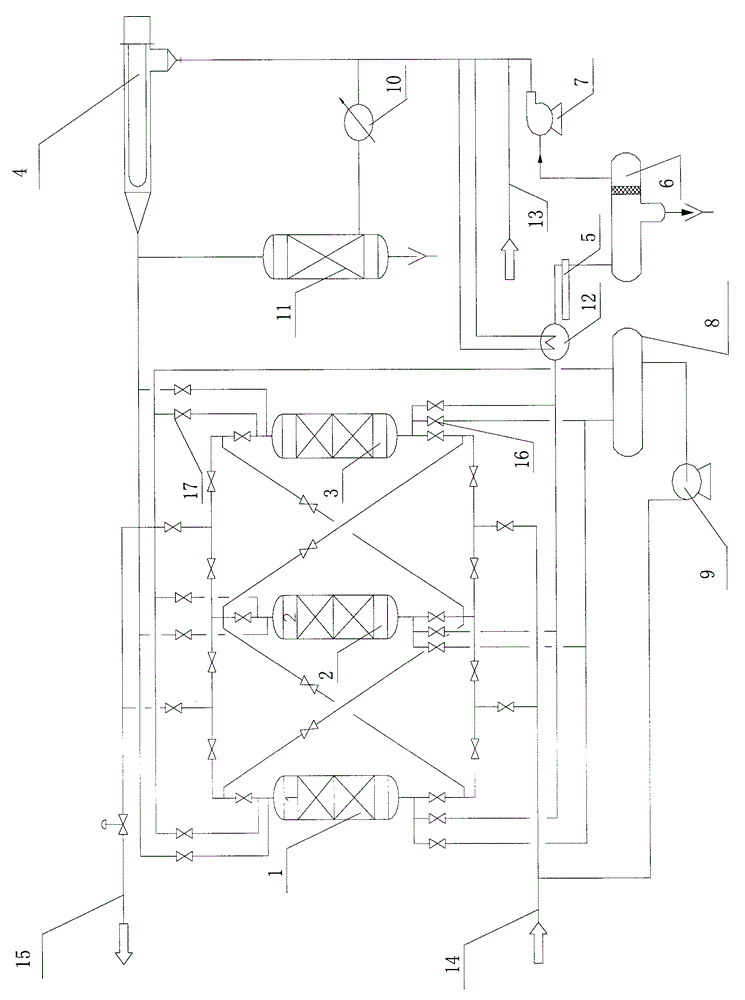

Image

Examples

Embodiment 1

[0037] The raw material composition of C4 fraction is shown in Table 1. The processing capacity is 10000kg / h, the operating elasticity is 60-110%, and the density is 540kg / m 3 , Operating temperature: 40°C, operating pressure: 1.5MPa(G).

[0038] Table 1 Composition of C4 fraction feedstock

[0039] name

mass percentage

1.06

n-butane

5.15

0.22

17.4

0.07

30.23

Anti-butene

45.53

Butadiene

100ppm

carbon five

0.12

0.01

tert-butanol

0.01

water

300ppm

0.11

total

99.91

[0040] The content of propane and C4 olefins in the C4 fraction is 76.89% by mass, the filling ratio of the upper part 3A and the lower part 4A in the molecular sieve dehydration tower is 6:4, the effective adsorption capacity of the 3A molecular sieve is 5% by mass, and the e...

Embodiment 2

[0048] The raw material composition of C4 fraction is shown in Table 2. The processing capacity is 10000kg / h, the operating elasticity is 60-110%, and the density is 545kg / m 3 , Operating temperature: 40°C, operating pressure: 1.5MPa(G).

[0049] Table 2 Composition of C4 fraction feedstock

[0050] name

Mass percentage (wt%)

Propylene

0.06

0.08

n-butane

9.06

40.43

15.13

0.57

Butene

16.06

Anti-butene

18.54

carbon five

0.003

0.005

tert-butanol

0.01

water

500ppm

[0051] Dimethyl ether

0.05

total

100.0

[0052] Propane and carbon four olefins content 50.44% mass percent in the C4 fraction, the filling ratio of upper part 3A and lower part 4A in the molecular sieve dehydration tower is 5: 5. The effective adsorption capacity of 3A molecular sieve take...

Embodiment 3

[0060] The raw material composition of C4 fraction is shown in Table 3. The processing capacity is 10000kg / h, the operating elasticity is 60-110%, and the density is 545kg / m 3 , Operating temperature: 40°C, operating pressure: 1.5MPa(G).

[0061] Table 3 Composition of C4 Fraction Feedstock

[0062] name

Mass percentage (wt%)

Propylene

0.06

propane

0.08

n-butane

9.06

42.43

Butene

13.13

0.57

Butene

16.02

Anti-butene

18.52

carbon five

0.003

0.005

tert-butanol

0.01

water

500ppm

0.05

total

100.0

[0063] The content of propane and C4 olefins in the C4 fraction is 48.38% by mass, and the filling ratio of the upper part 3A and the lower part 4A in the molecular sieve dehydration tower is 4:6. The effective adsorption capacity of the 3A molecular sieve is 5% by mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com