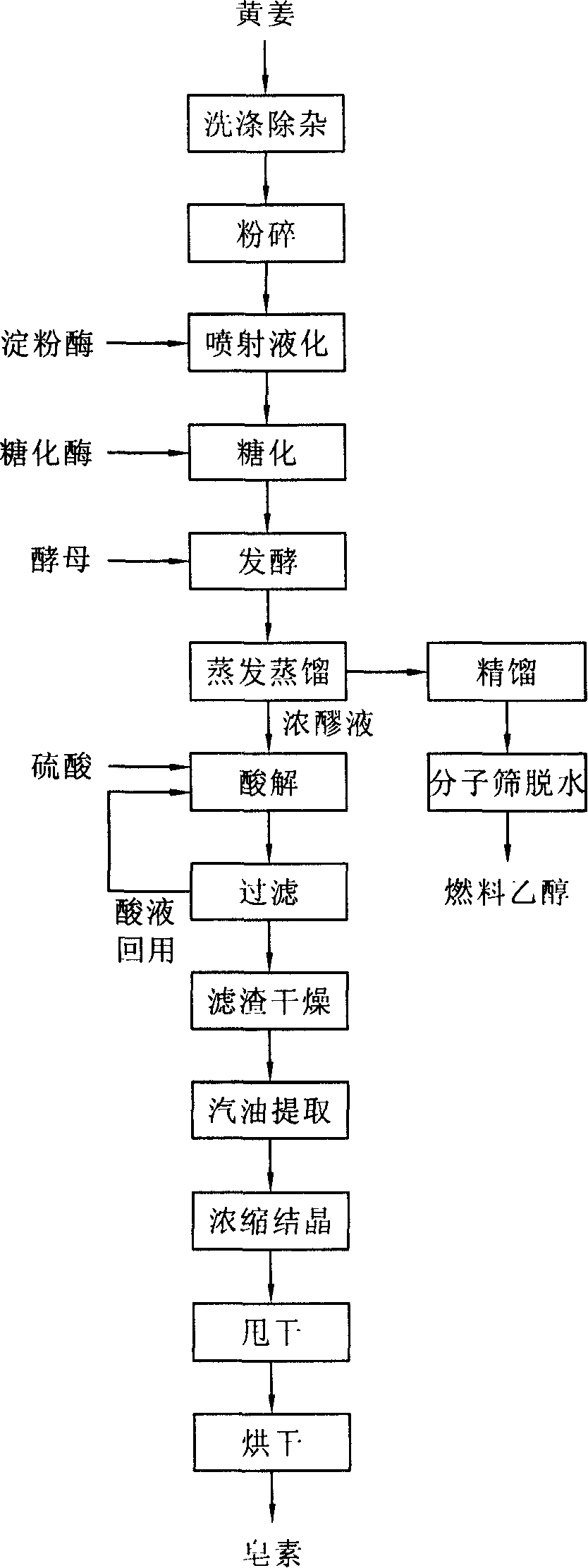

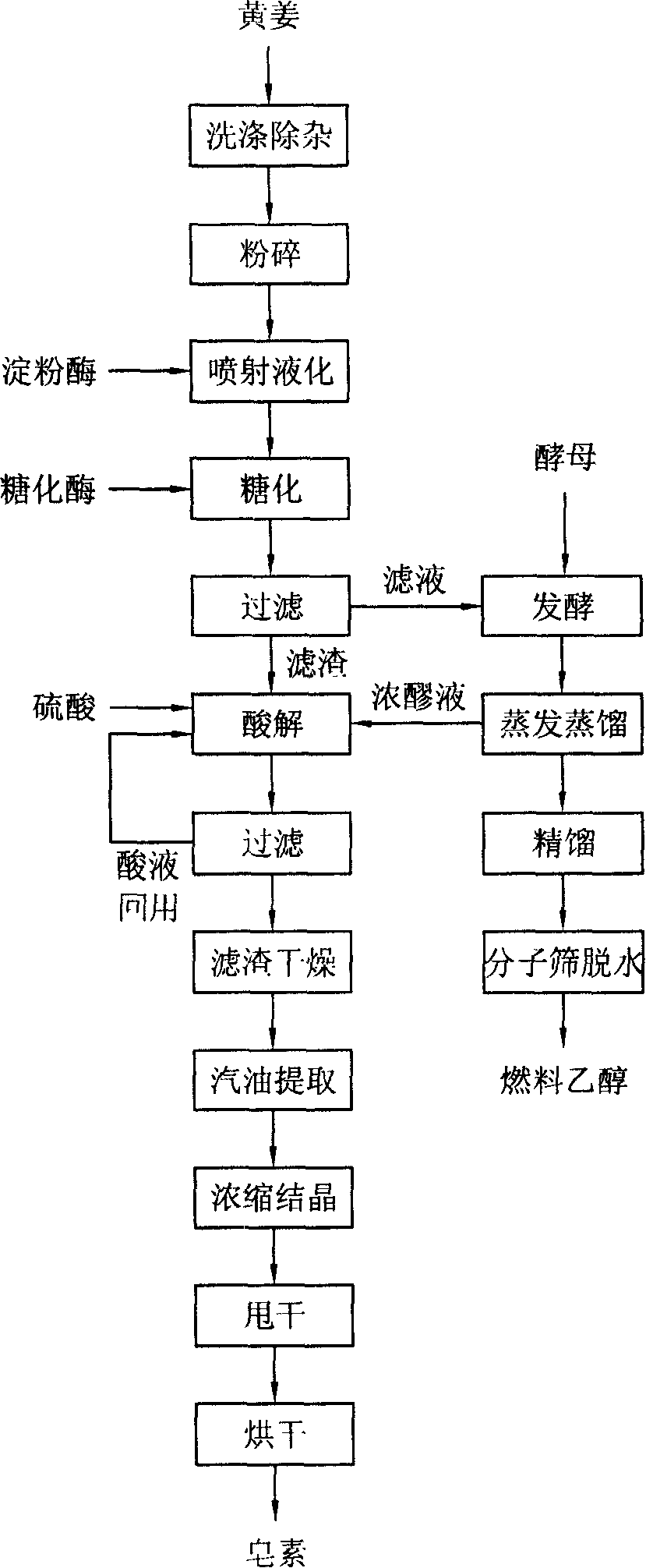

Clean producing technique for extracting saponin from turmeric and coproducing fuel ethanol

A clean production, fuel ethanol technology, applied in the fields of biofuels, steroids, organic chemistry, etc., can solve the problems of high energy consumption and low saponin yield, reduce waste water discharge, easy industrialization and large-scale scale The effect of optimistic production and sales prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Wash fresh turmeric (or dried turmeric after soaking in water) to remove impurities, grind it into a slurry (containing fiber), control the particle size to <2mm, put it in a mixing tank with a stirrer, heat and preheat to 65°C, press 1.5u Add high-temperature-resistant α-amylase to / g turmeric twice, add 30% of the total amount for the first time, heat up to 90°C, and cook for 30 minutes. Then enter the jet liquefier for jet liquefaction, control the temperature in the jet to 104°C, and stay for 10 minutes. The mash after the first liquefaction is flashed in a vacuum flash tank to cool down to 90°C, put into the liquefaction tank, and add The remaining high-temperature-resistant α-amylase was liquefied for the second time, and the control time was 100 minutes. Cool the liquefied mash to 60°C, adjust the pH to 4.5 with sulfuric acid, add glucoamylase for saccharification, and control the time for 20 minutes.

[0031] Put the saccharification mash into the fermentation ...

Embodiment 2

[0035] Wash fresh turmeric (or dried turmeric after soaking in water) to remove impurities, grind it into a slurry (containing fiber), control the particle size to <2mm, put it in a mixing tank with a stirrer, heat and preheat to 65°C, press 1.5u Add high-temperature-resistant α-amylase to / g turmeric twice, add 30% of the total amount for the first time, heat up to 90°C, and cook for 30 minutes. Then enter the jet liquefier for jet liquefaction, control the temperature in the jet liquefier to 104°C, and stay for 10 minutes. The mash after the first liquefaction is flashed and cooled to 90°C in a vacuum flash tank, and put into the liquefaction tank. Add the remaining high-temperature-resistant α-amylase for the second liquefaction, and control the time for 100 minutes. Cool the liquefied mash to 60°C, adjust the pH to 4.5 with sulfuric acid, add glucoamylase for saccharification, and control the time for 20 minutes.

[0036] Filtrate the fiber-containing mash to obtain sugar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com