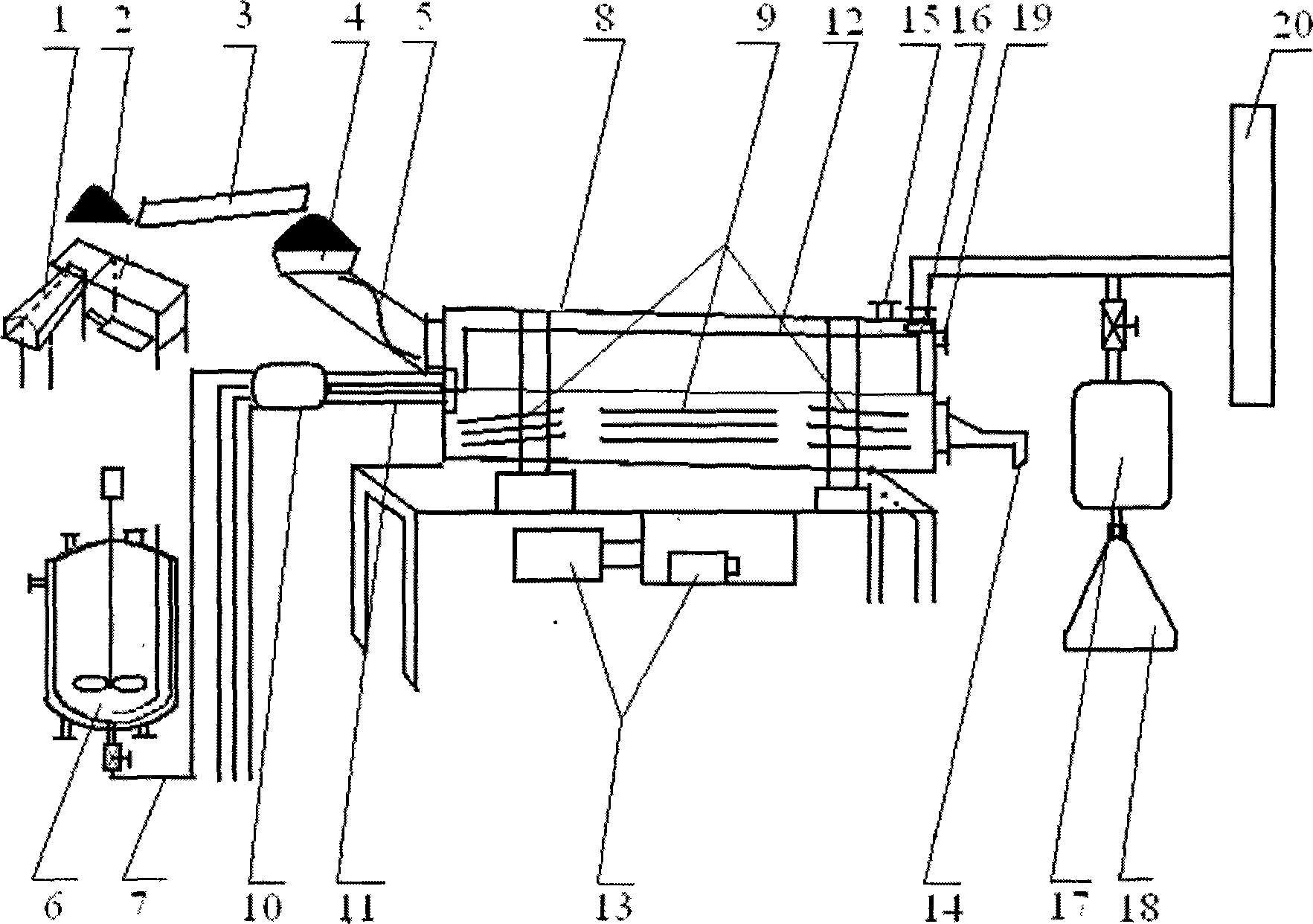

Fermentation / distillation integrated technique apparatus for producing alcohol from sugar

A fuel ethanol and sugar technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermenter combinations, etc., can solve the problem of high energy consumption, low efficiency and difficulty in mechanization of juice pretreatment. and other problems, to achieve the effect of enhancing the migration of bacteria, simplifying the process flow, and reducing the loss of volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A retort device (13.7 cm in height, 15.7 cm in diameter) was used to separate ethanol from the solid fermentation material of sweet sorghum stalk by gas (steam) stripping. Experiments were carried out on different amounts of fermented materials by using the gradient feeding method, and the optimal filling height and heat medium (dry hot air, CO 2 and 3.5kg / cm 2 Superheated steam) flow rate, wine gas (steam) is collected after condensing through the spiral plate heat exchanger. For example, under optimized working conditions, 300-600g of fermentation material (water concentration 70-85%, ethanol mass concentration 5-10%) is added in a single batch, and dry hot air is used as the heating medium, and the temperature is 85-95 ℃. The stripping time is 40-80 minutes, the volume concentration of ethanol in the gas-phase condensate is 15-35%, the volume concentration of ethanol in the slag is lower than 0.5%, and the actual ethanol yield is in the range of 88-95%.

Embodiment 2

[0029] In the self-developed 50L horizontal drum solid-state fermentation / distillation integrated device (diameter 300mm, length 700mm), multiple batches of tests were carried out on the continuous gas (steam) stripping of ethanol in the fermentation material and the drying of the slag. The rotary joint realizes the continuous entry and exit of the gaseous heat medium during the rotation of the fermenter cylinder. For example, sweet sorghum stalk solids are fermented with hot CO 2 Recover ethanol for the stripping medium, solid fermentation material (water concentration filling coefficient is 0.3~0.7, flow rate is 2~8L / min, temperature is 80~105 ℃, ethanol vapor is condensed through spiral plate high-efficiency heat exchanger, and stripping time is 90 ~120min, the volume concentration of ethanol in the condensate is 10~60%, the volume concentration of ethanol in the slag is lower than 0.2%, and the actual ethanol yield is 85~94%. Continue to heat CO 2(Simulated flue gas) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com