Gas ultrasonic flowmeter with full-zero-section detection flow channel structure and detection method thereof

An ultrasonic flowmeter and cross-sectional detection technology, which is applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., can solve problems such as low measurement accuracy, many movable parts, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

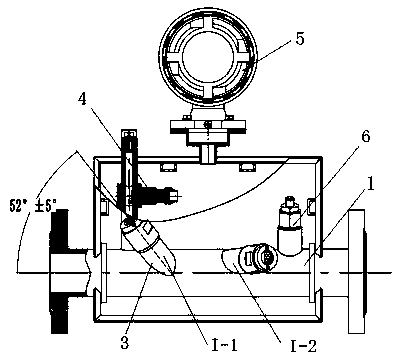

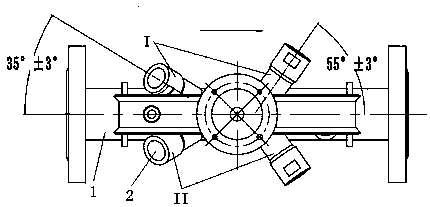

[0024] The gas ultrasonic flowmeter with a full zero cross-section detection flow channel structure of the present invention includes a gas flow channel with a circular cross section, and at least two pairs of sound channels are arranged on the gas flow channel 1, and each pair of sound channels is located on the top of the circular flow channel. Downstream, there is an installation hole 2 for installing the ultrasonic transducer assembly A on the sound channel, and the ultrasonic transducer assembly A is arranged in the sound channel, and each pair of two ultrasonic transducer assemblies A alternately emits and receives ultrasonic waves, and the ultrasonic emission After being reflected twice by the pipe wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com