Injection-type paint supply system

An injection-type, paint-supplying technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of inconvenient addition or replacement of paint, low flow accuracy and unsuitable for low-viscosity paint, etc., to achieve environmental protection treatment, Fast cleaning and color change, reasonable and novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

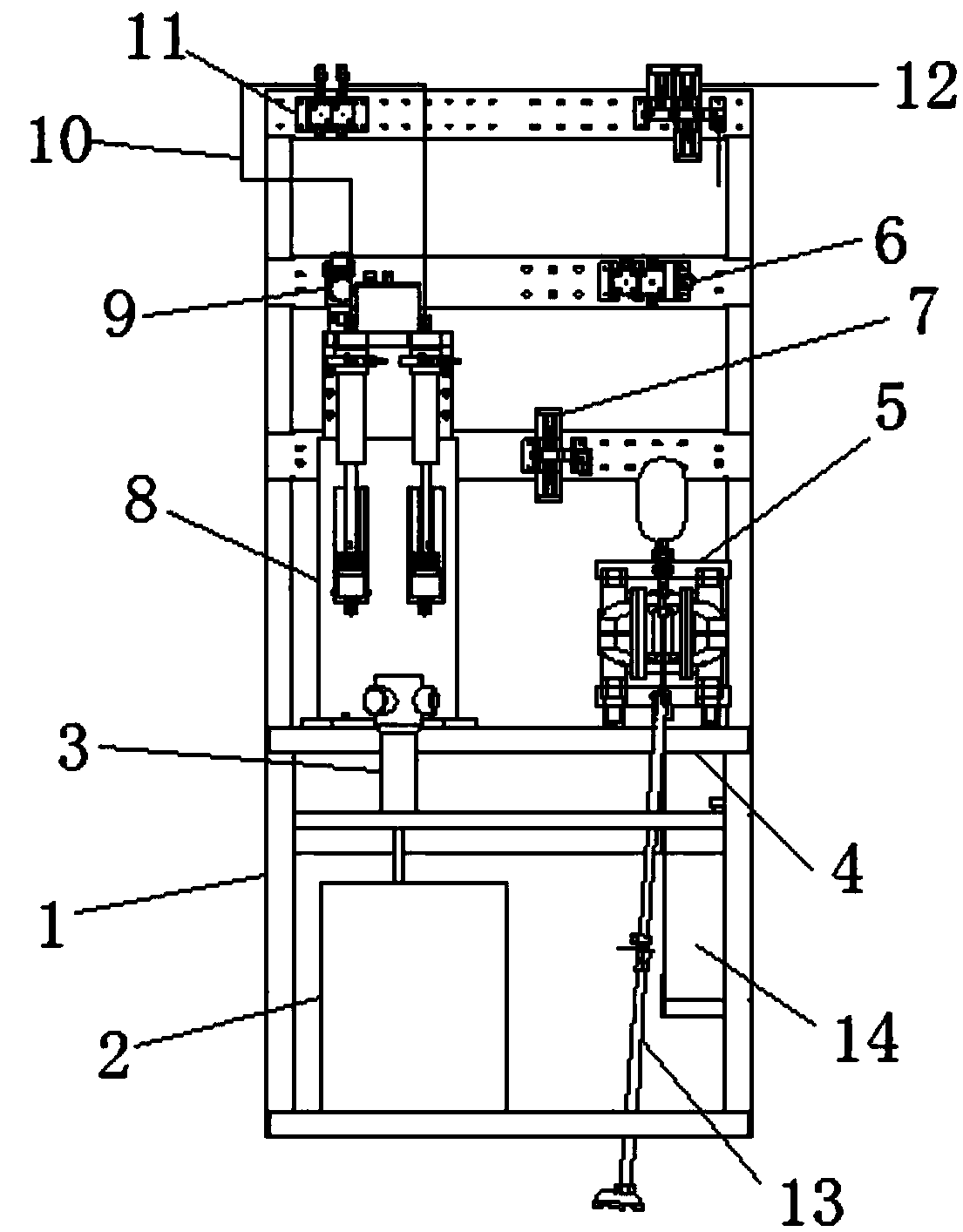

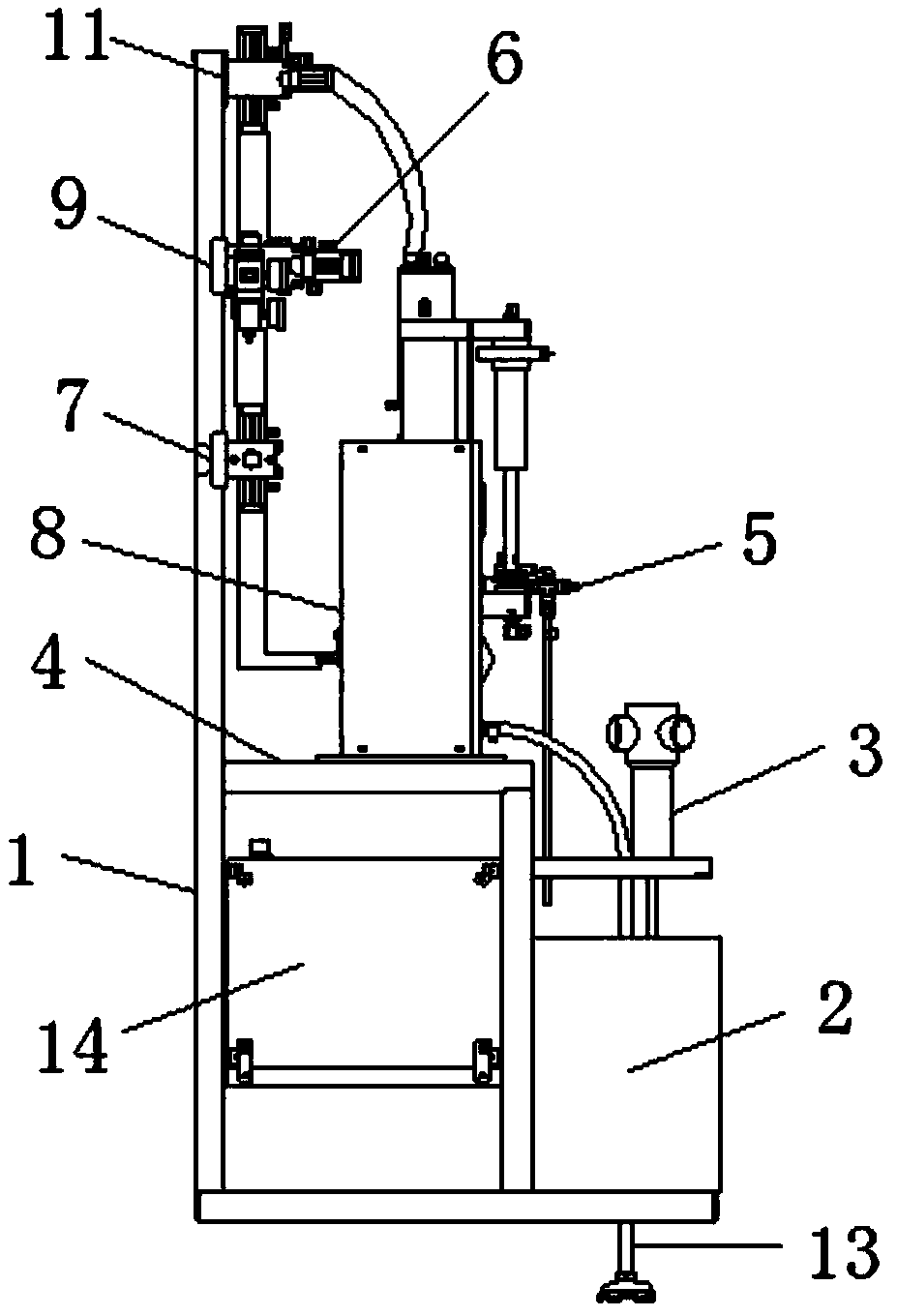

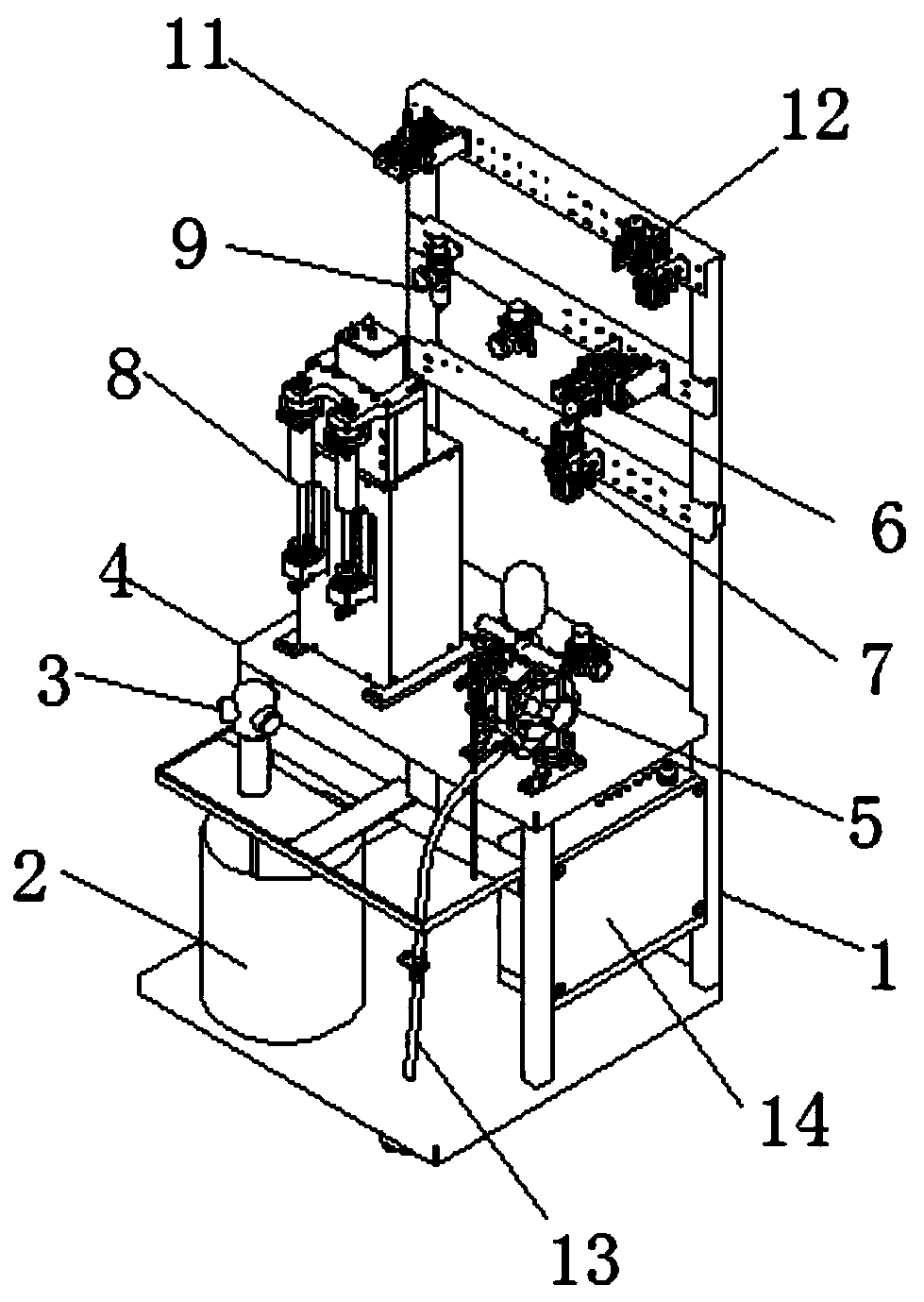

[0024] Such as Figure 1-3 As shown, an injection paint supply system includes a frame 1, a paint bucket 2 and a partition 4, the paint bucket 2 is placed on one side of the frame 1, and the partition 4 is fixedly welded on one side of the frame 1 wall, one side of the partition 4 is fixedly connected with an agitator 3, and the output end of the agitator 3 is located in the inner cavity of the paint bucket 2, the surface of the partition 4 is fixed with a diaphragm pump 5 through a screw, and the top of the diaphragm pump 5 is A paint color change valve 6 is fixedly installed on the surface of the frame 1, a feed distribution valve 7 is fixed on one side of the paint color change valve 6, and a paint injection valve 8 is fixed on the surface of the partition 4 on one side of the diaphragm pump 5, The top of the paint injection valve 8 is located on the surface of the frame 1, and an air source decompression filter 9 is fixedly installed. One side of the air source decompressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com