Electronic expansion valve

A technology of electronic expansion valve and valve seat, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of low flow adjustment accuracy and unable to adjust flow normally, and achieve the effect of improving flow accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

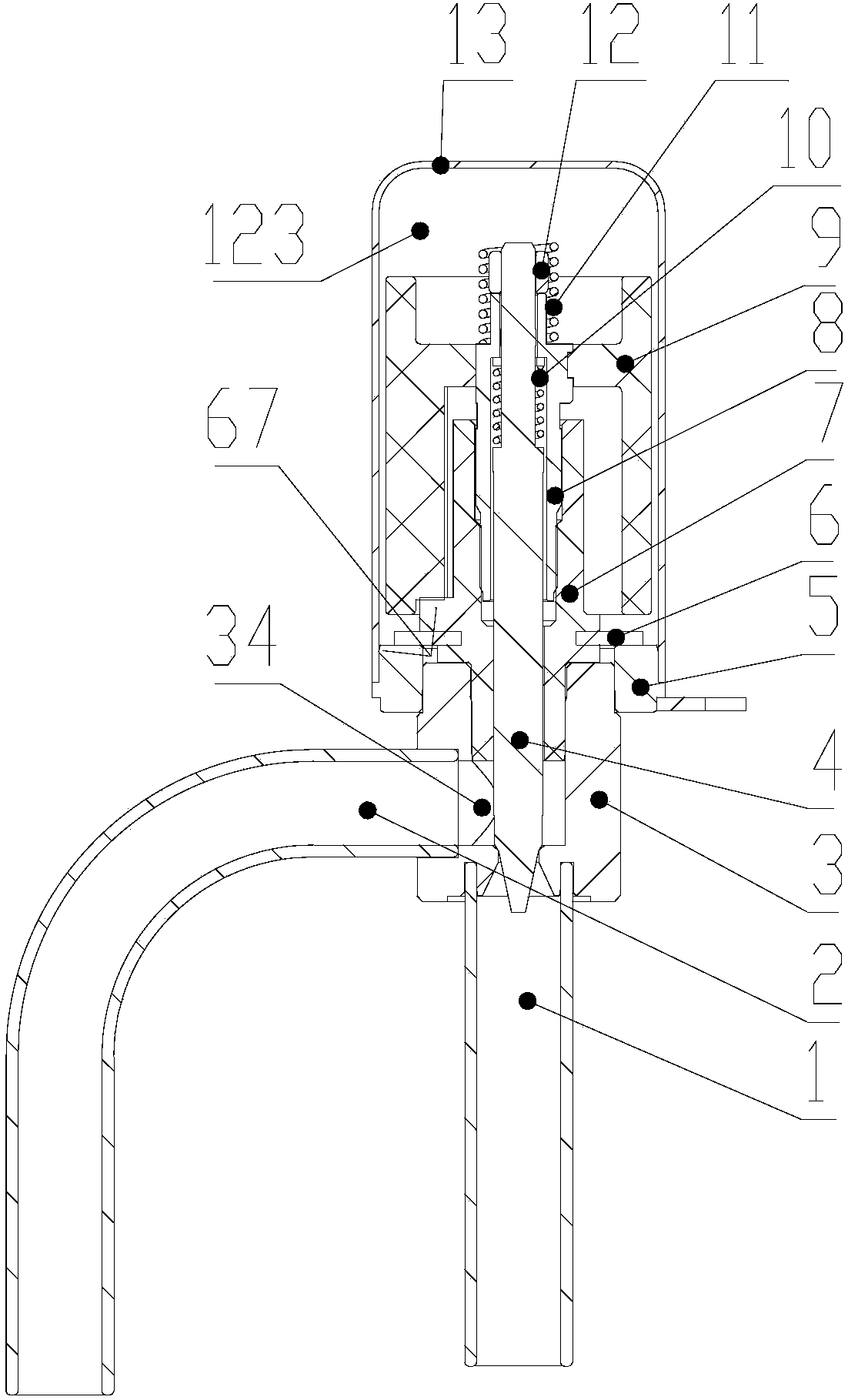

[0043] Please refer to Figure 1-Figure 6 As shown, the embodiment of the present invention provides an electronic expansion valve, including: a valve seat assembly, a nut assembly, a valve needle assembly, a rotor assembly and a bushing assembly.

[0044] The valve seat assembly includes a valve seat 3 , a first connecting pipe 2 connected to one side of the valve seat 3 , a second connecting pipe 1 connected to the lower part of the valve seat, and a sleeve seat 5 arranged on the valve seat 3 .

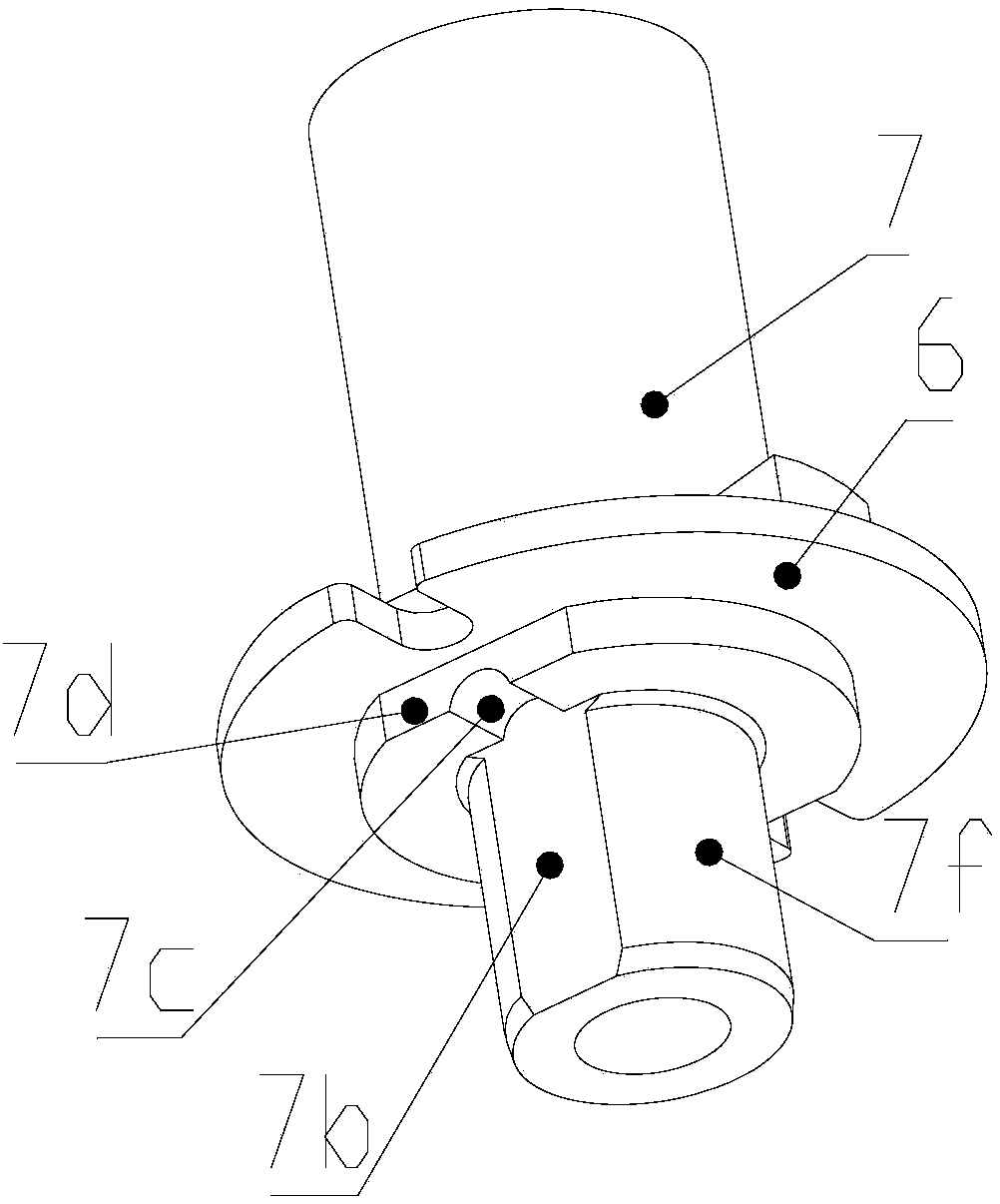

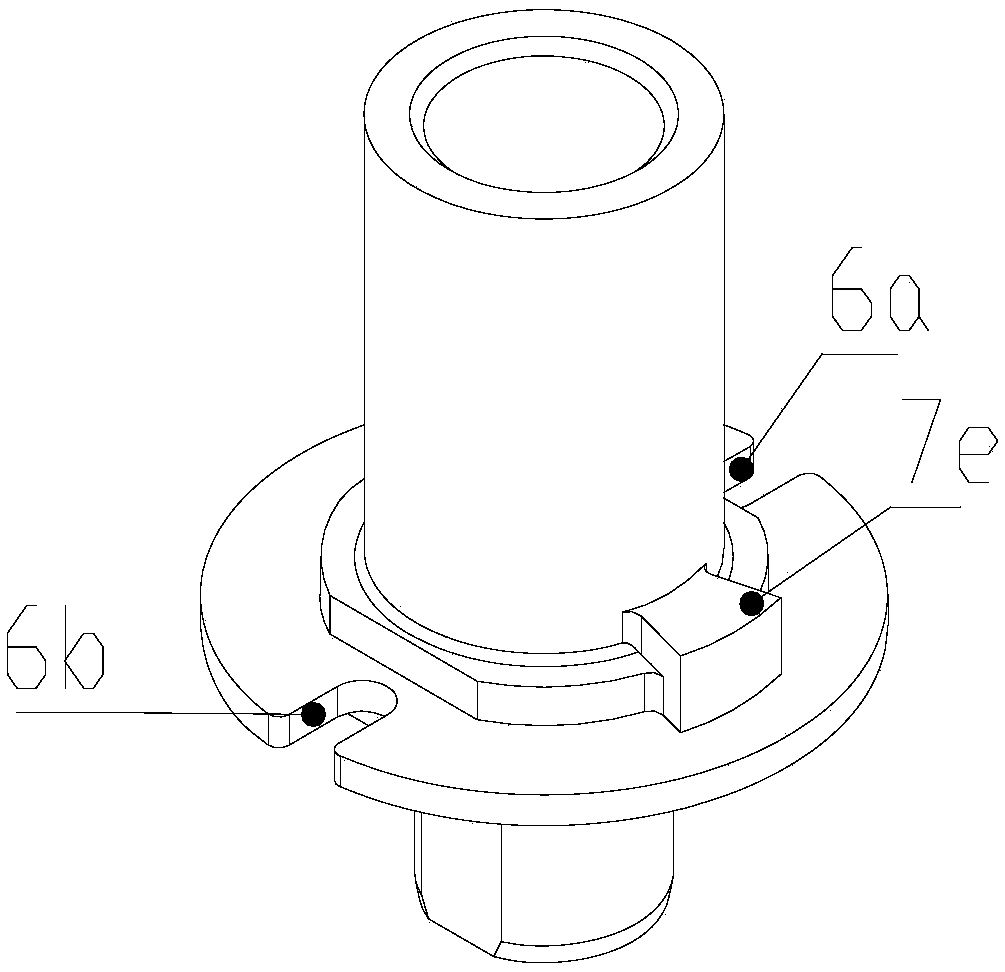

[0045] The nut assembly includes a nut 7 and a connecting plate 6 arranged on the outer ring of the middle section of the nut 7 . The connecting plate 6 is welded on the casing seat 5 . At least one first plate notch 6b is provided on the connecting plate 6, and the second plate notch 6a may also be provided, and of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com