Regenerative refrigerator

a refrigerator and regenerative technology, applied in refrigeration machines, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of lead use restrictions, indium is a very soft metal, and cannot be used as a regenerative material, etc., and achieves low thermal conductivity and high air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]However, in the case of mixing bismuth with other regenerator materials as described above, it is difficult to determine the mixture ratio of bismuth and other regenerator materials. Further, there is also the problem of an increase in the prices of regenerative refrigerators because other regenerator materials, which may be used as normal regenerator materials, are expensive.

[0032]According to one aspect of the present invention, a regenerative refrigerator may be provided that is capable of attaining cryogenic temperatures lower than or equal to 15 K while using bismuth as a regenerator material.

[0033]A description is given below, with reference to the accompanying drawings, of embodiments of the present invention.

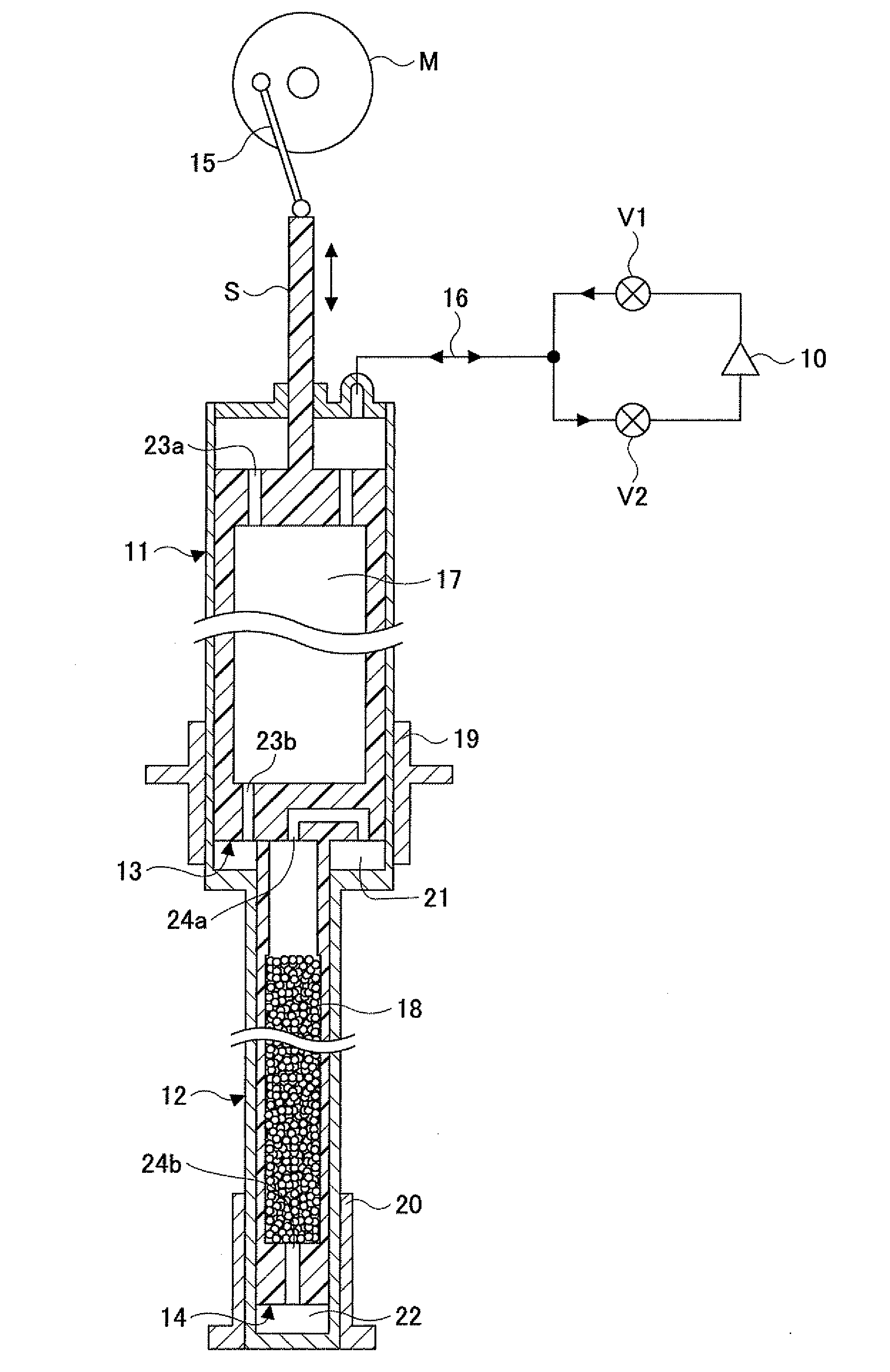

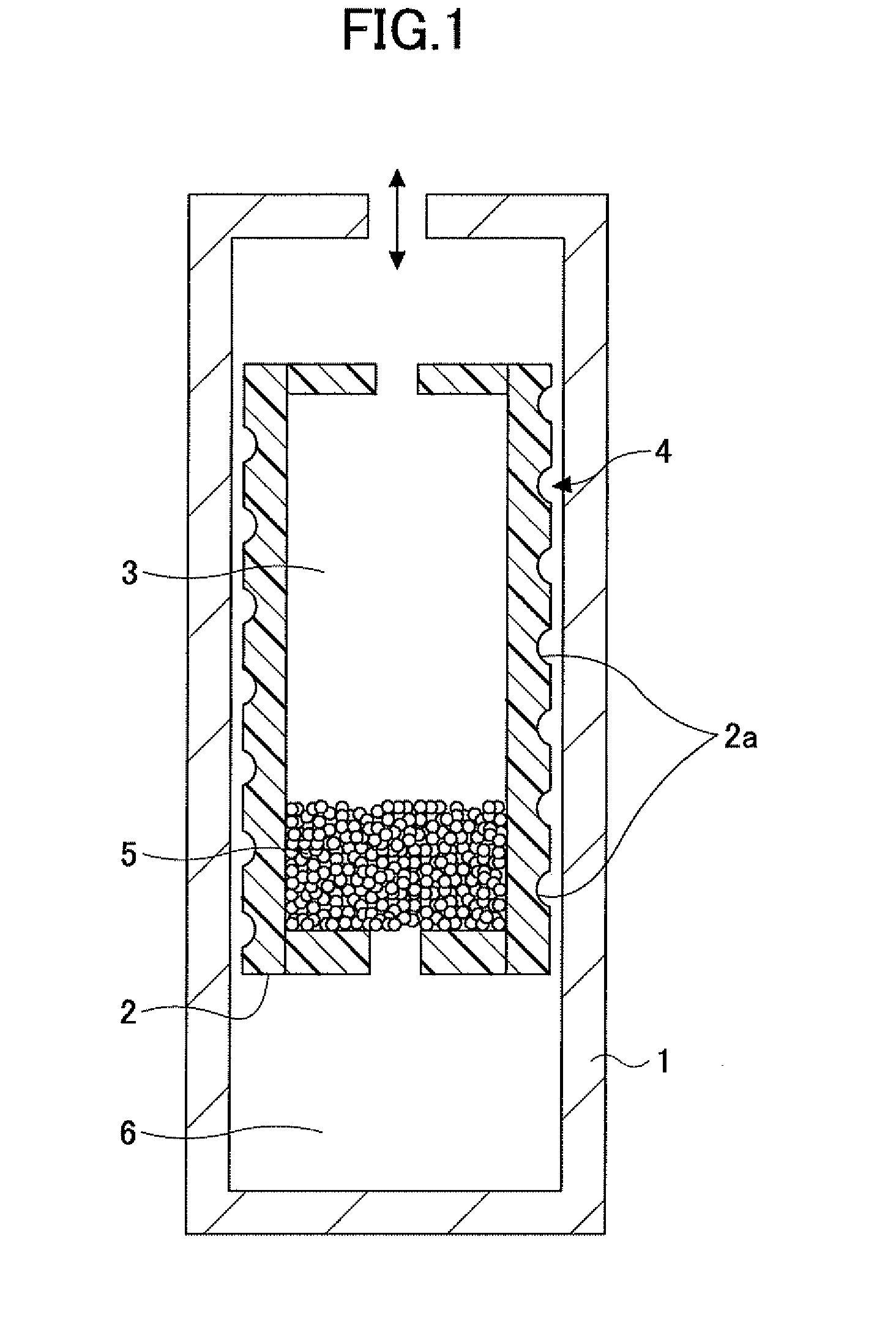

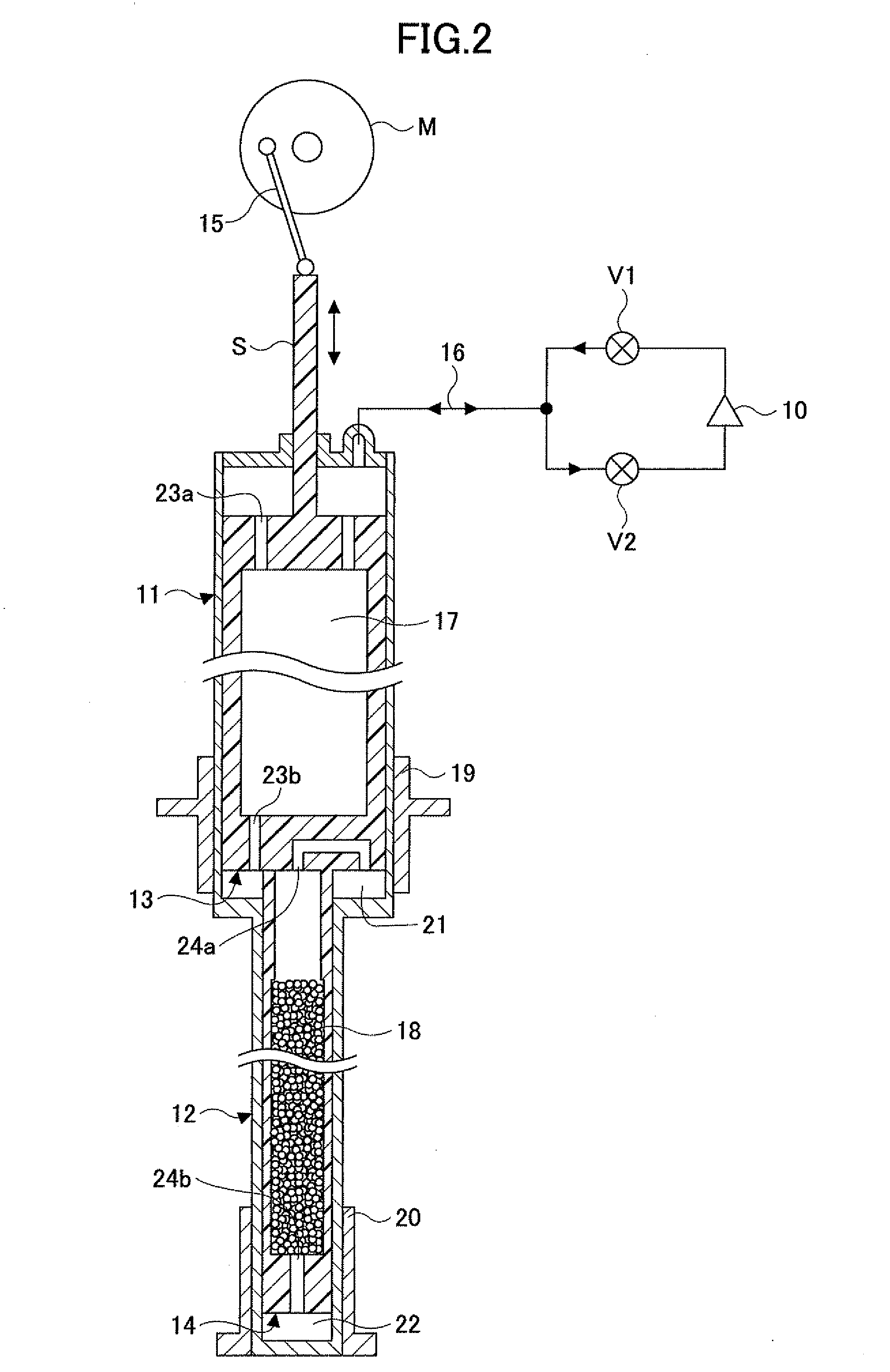

[0034]FIG. 1 is a diagram illustrating a basic configuration of a regenerative refrigerator according to a first embodiment of the present invention. The regenerative refrigerator includes a cylinder 1 and a cylindrical displacer 2 provided in the cylinder 1. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com