System and method for forming hydrophobic structures in a hydrophilic print medium

A printing medium, hydrophobic technology, used in printing devices, conductive pattern formation, post-processing of printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

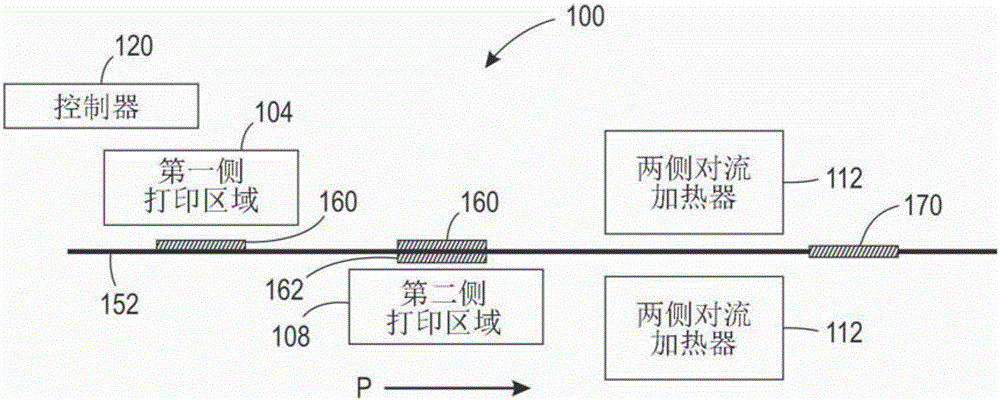

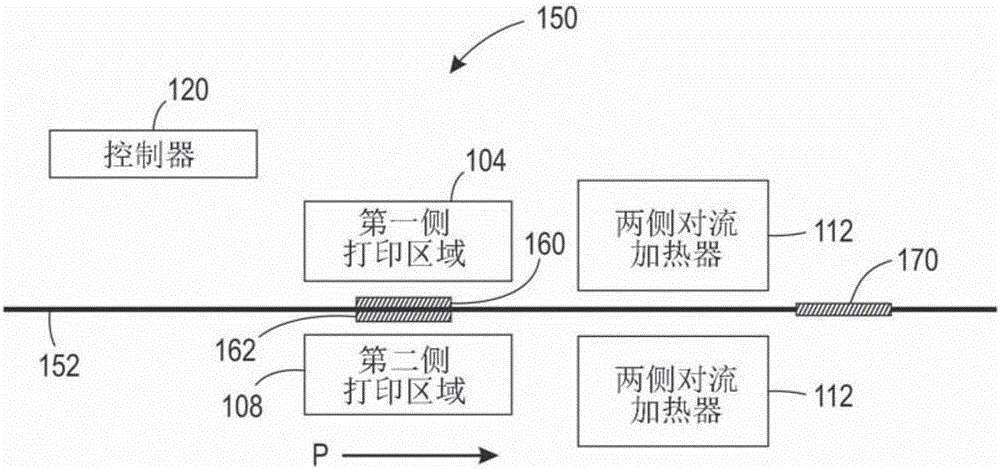

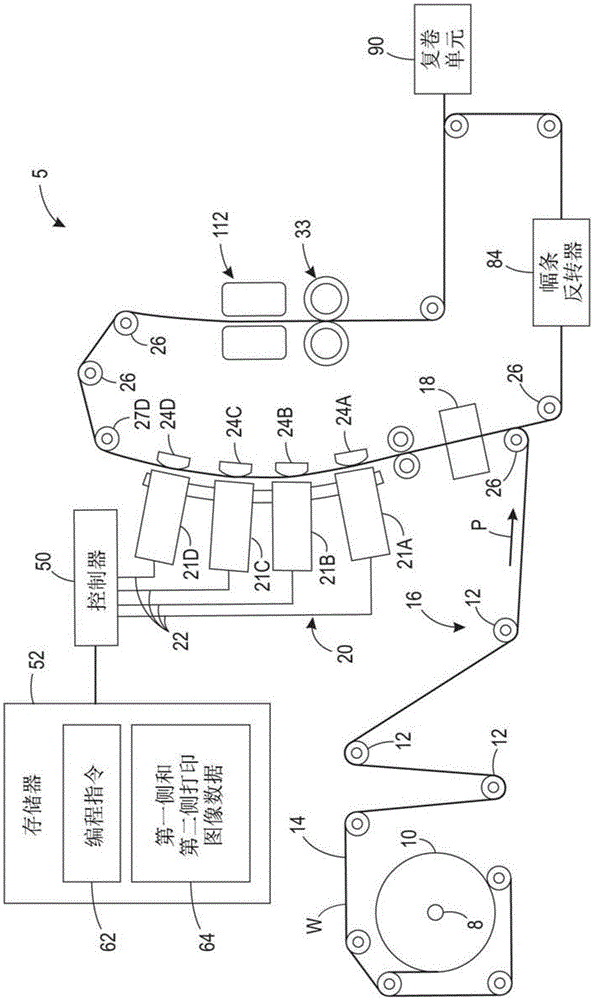

[0017] For a general understanding of the context of, and details of, the systems and methods disclosed herein, reference is made to the accompanying drawings. In the drawings, like reference numerals are used to refer to like elements throughout. As used herein, the term "printer" includes any device that produces an image on a medium with resin or colorant, such as a digital copier, book-finishing machine, facsimile machine, multifunction machine, and the like. In the description below, the printer is also configured to deposit molten wax, phase change ink, or other hydrophobic material onto a porous substrate such as paper. Although the printers described below are inkjet printers and in some embodiments the hydrophobic phase change material may be phase change ink, in some configurations the hydrophobic material is an optically clear wax or other material that does not have a particular color. The visual representation of the hydrophobic material provided below is for exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com