Well Servicing Rig and Manifold Assembly

a technology for servicing rigs and manifolds, which is applied in the direction of drilling machines and methods, drilling accessories, fluid removal, etc., can solve the problems of high labor intensity, large work area footprint created by such set-ups, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

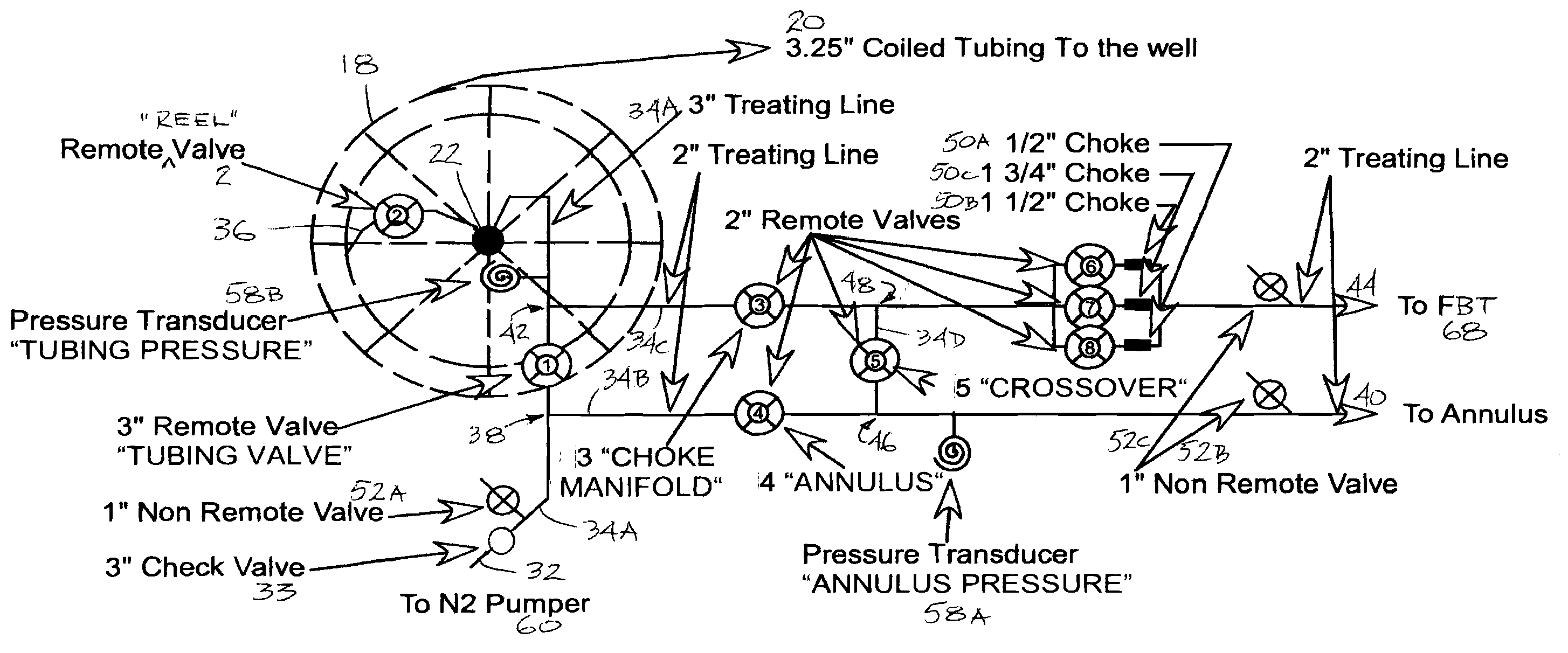

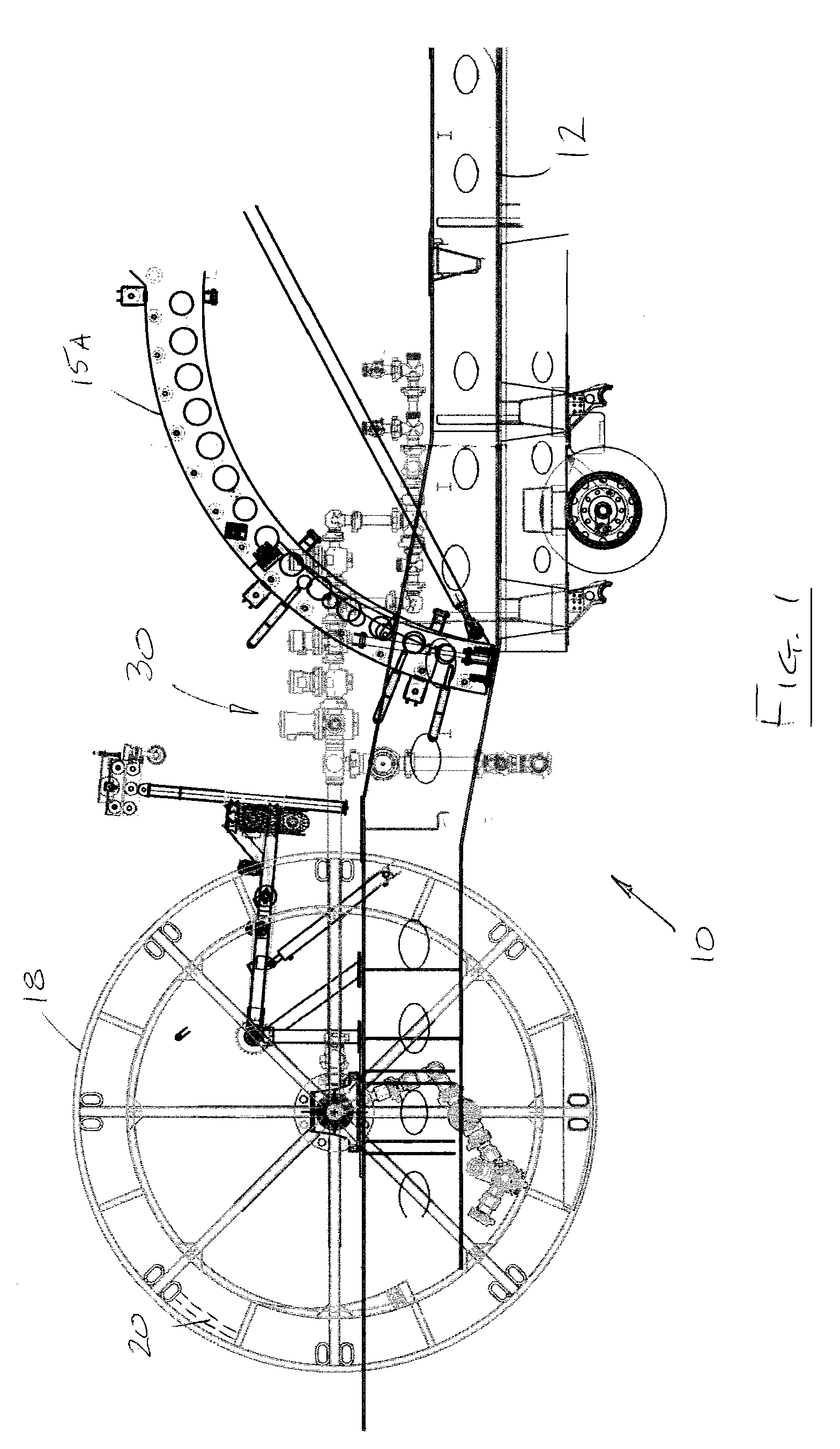

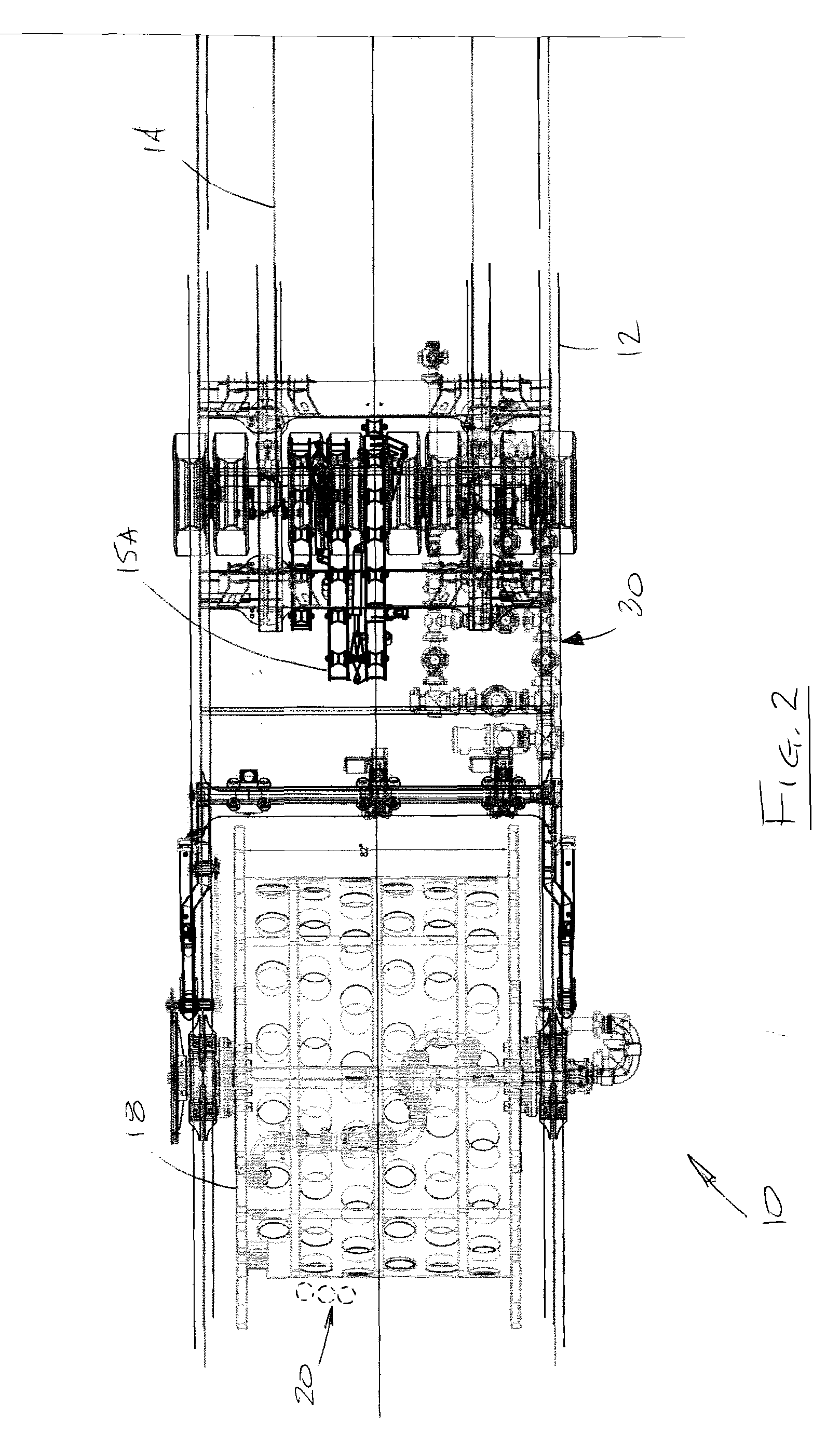

[0032] Reference is first made to FIGS. 1 to 3c which show a servicing unit for an underground formation which in the preferred embodiment is in the form of a coiled tubing unit, or rig, generally indicated by the reference numeral 10. The present rig can service various types of hydrocarbon bearing formations, including coal formations (or beds). It is suited for typical coiled tubing functions, such as conventional stimulation operations relating to coiled tubing, as well as for fracturing (“fracing”) operations of coal beds to enhance production of coal bed methane.

[0033] Some of the basic components of the rig are a base, a mast pivotally mounted relative to the base, and servicing equipment for a well, or wellbore, leading to the underground formation. “Servicing” is defined herein as typical functions related to coiled tubing, including stimulation and fracing operations. The base is a mobile carrier in the form of a wheeled trailer 12 adapted to be pulled by a motorized vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com