Combination yard maintenance apparatus

a maintenance apparatus and combinator technology, applied in the field of combinator yard maintenance apparatus, can solve the problems of large purchase and operating costs, large heat generation, and large friction disc surface area of friction discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Referring particularly to the drawings, the figures are for the purpose of illustrating embodiments of the invention only and not for the purpose of limiting same.

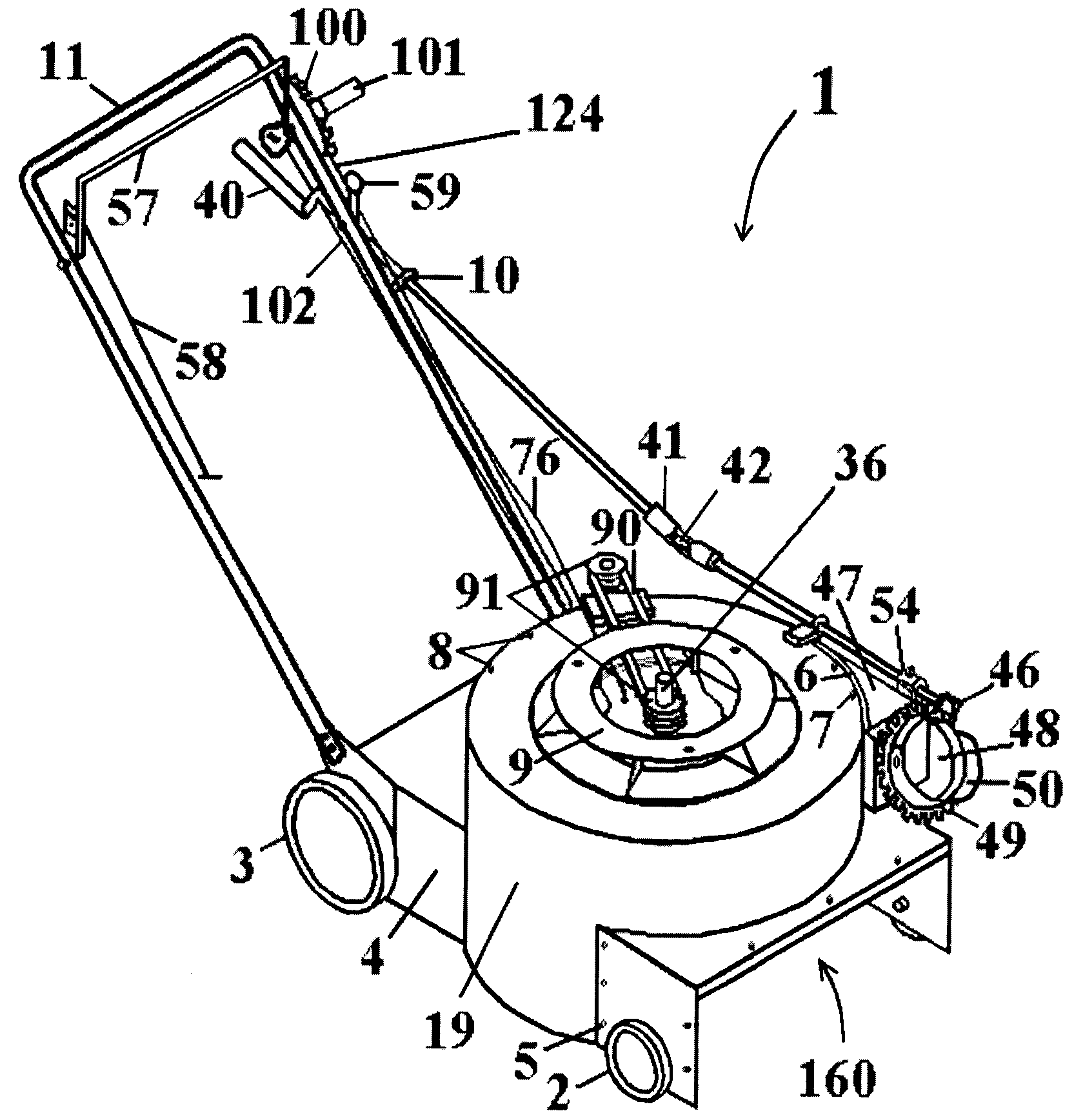

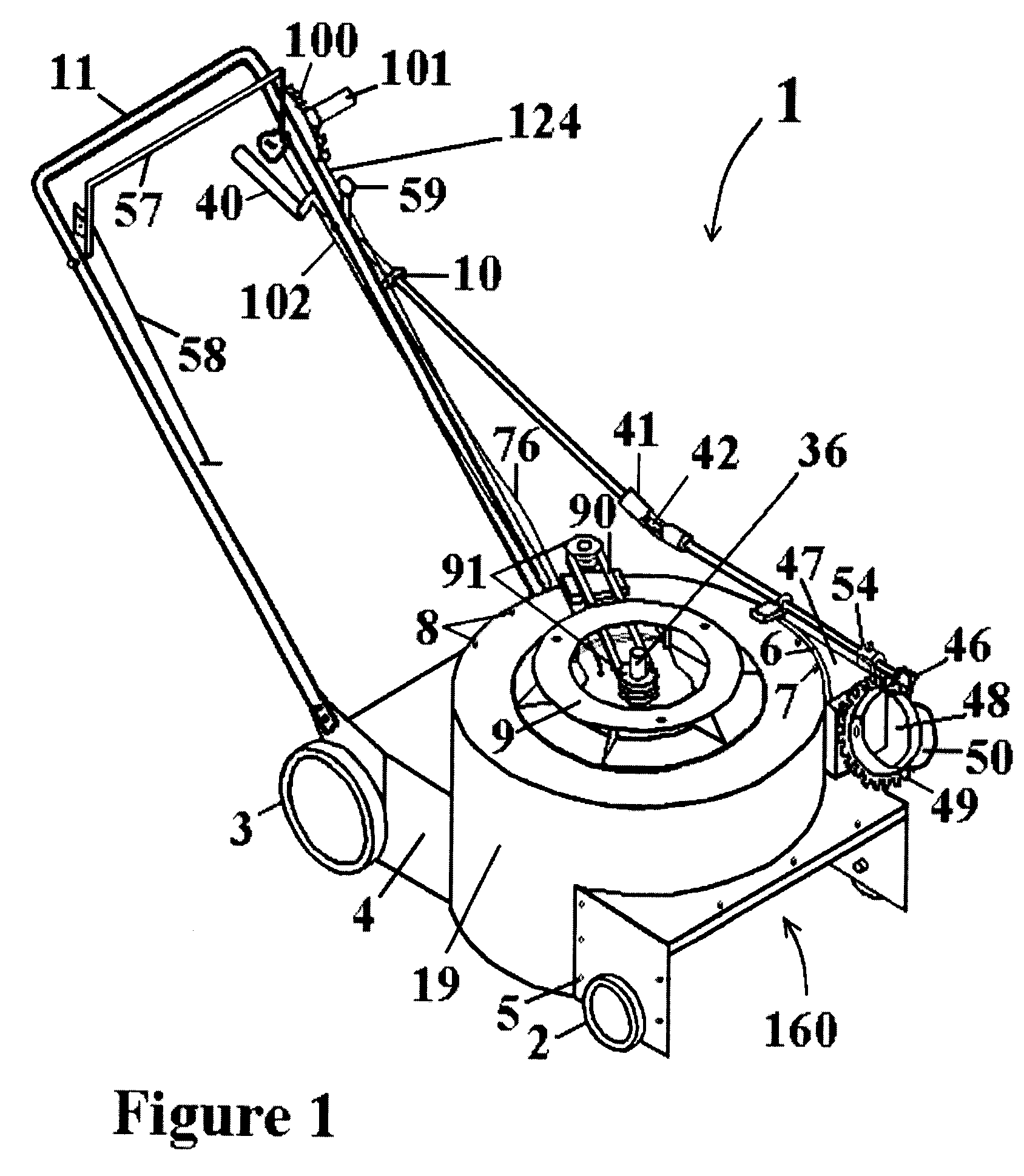

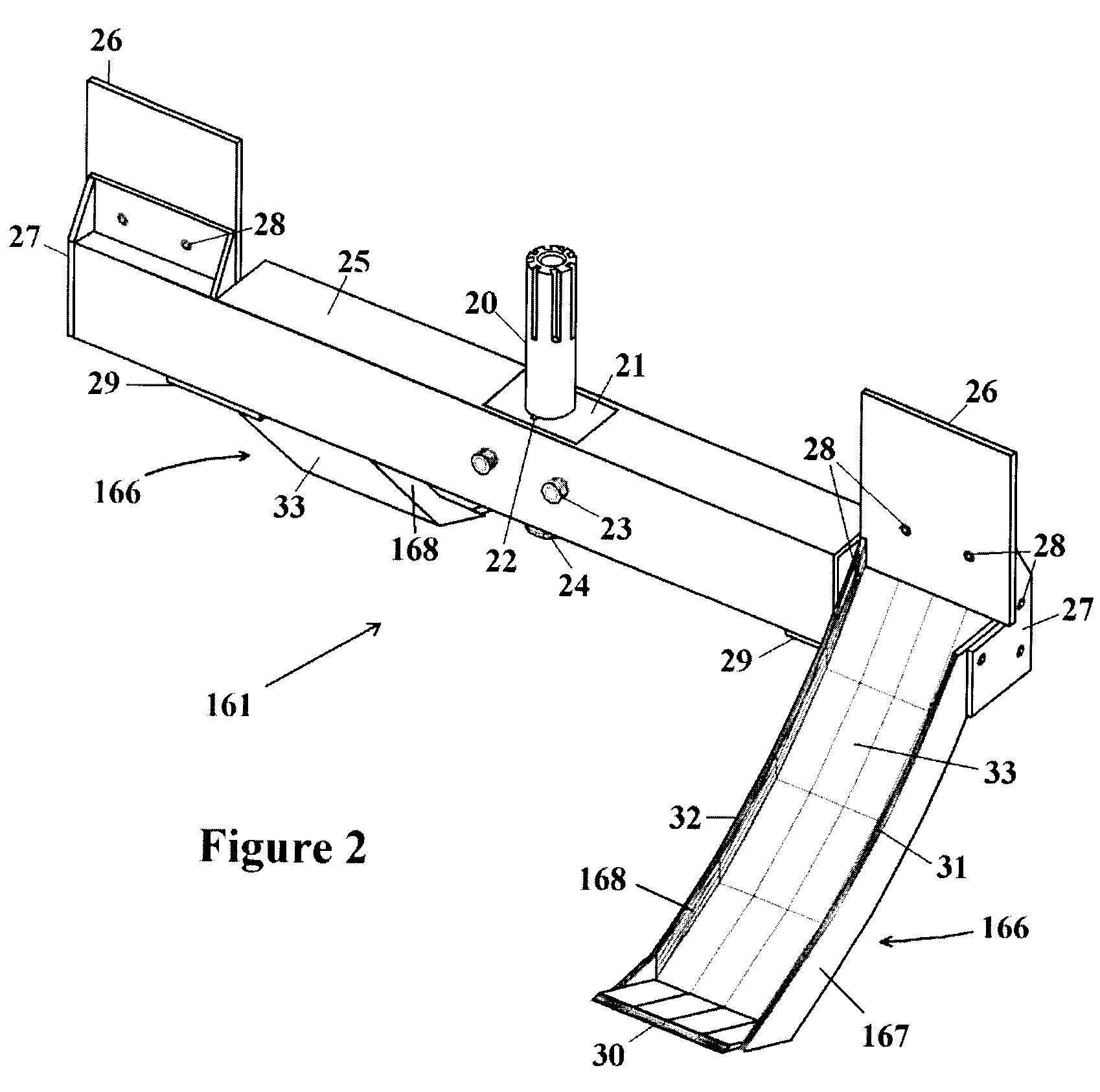

[0052]In FIG. 1, a combination yard maintenance apparatus 1 which is especially useful but not limited to mowing grass, clearing leaves and blowing snow is shown. The yard maintenance apparatus 1 comprises a chassis 4 with a cylindrical cavity 19 and a relatively light weight blade assembly that is rotatably mounted inside the cylindrical cavity 19 of the chassis 4. Different blade assembly configurations suitable for mounting into the chassis are shown as elements 161, 162 and 163 in FIGS. 2-7 and element 193 in FIG. 23. The yard maintenance apparatus 1 also has a push handle 11, two front wheels 2, and two rear wheels 3 wherein the height of the wheels 2 and 3 may be adjusted relative to the chassis 4. An engine brake bar control 57 and a brake-line cable 58 are also shown.

[0053]The annular platform 9 at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com