Height adjustable multi-roller transmission device

A transmission device and adjustable technology, applied in the directions of transportation, packaging, roller table, etc., can solve the problems of belt slippage, easy damage to the belt, inconvenient use, etc., and achieve the effect of convenient use and easy friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

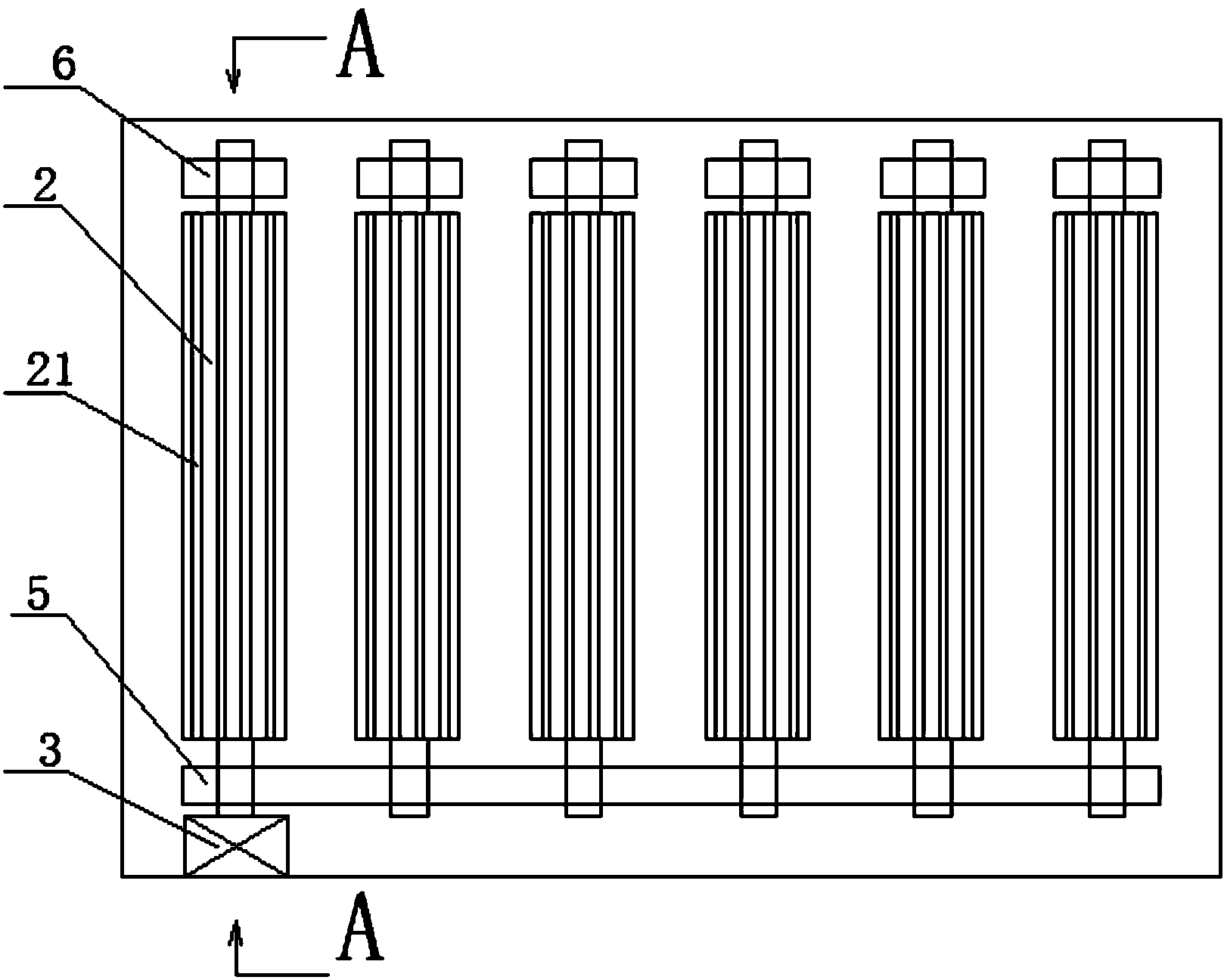

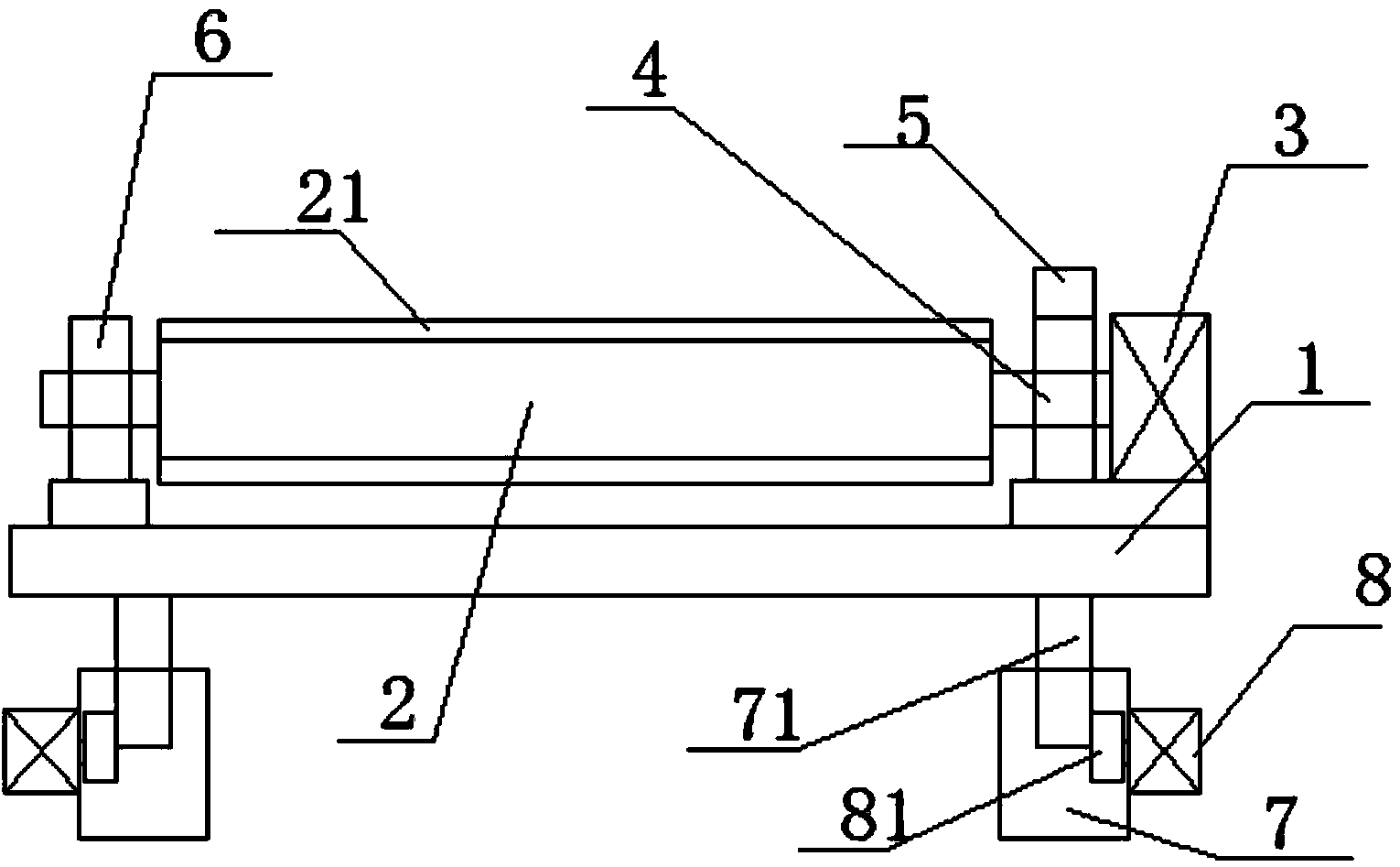

[0015] A height-adjustable multi-roller conveying device of this embodiment, such as figure 1 , 2 As shown, it includes a workbench, a motor, a bracket and more than one roller. The rollers are all positioned on the workbench through the bracket, and the two ends of the roller are connected to the bracket through bearings. At the same time, the roller The rollers are evenly distributed on the workbench; the same end of the rollers is provided with a sprocket, and the rollers are connected to each other through a sprocket and a chain, and the motor is connected to one of the sprockets; The roller is evenly provided with anti-skid grooves along the circumferential direction, and the anti-skid grooves are each on a straight line, and the anti-skid grooves extend to both ends of the roller; the workbench is provided with more than two sets of legs, and the legs include First and second legs, the first leg and the second leg are connected by sliding, the second leg is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com