Liquid transfer device and suction unit

a technology of liquid transfer device and suction unit, which is applied in the direction of positive displacement liquid engine, machine/engine, bend, etc., can solve the problem that the tube may suffer permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

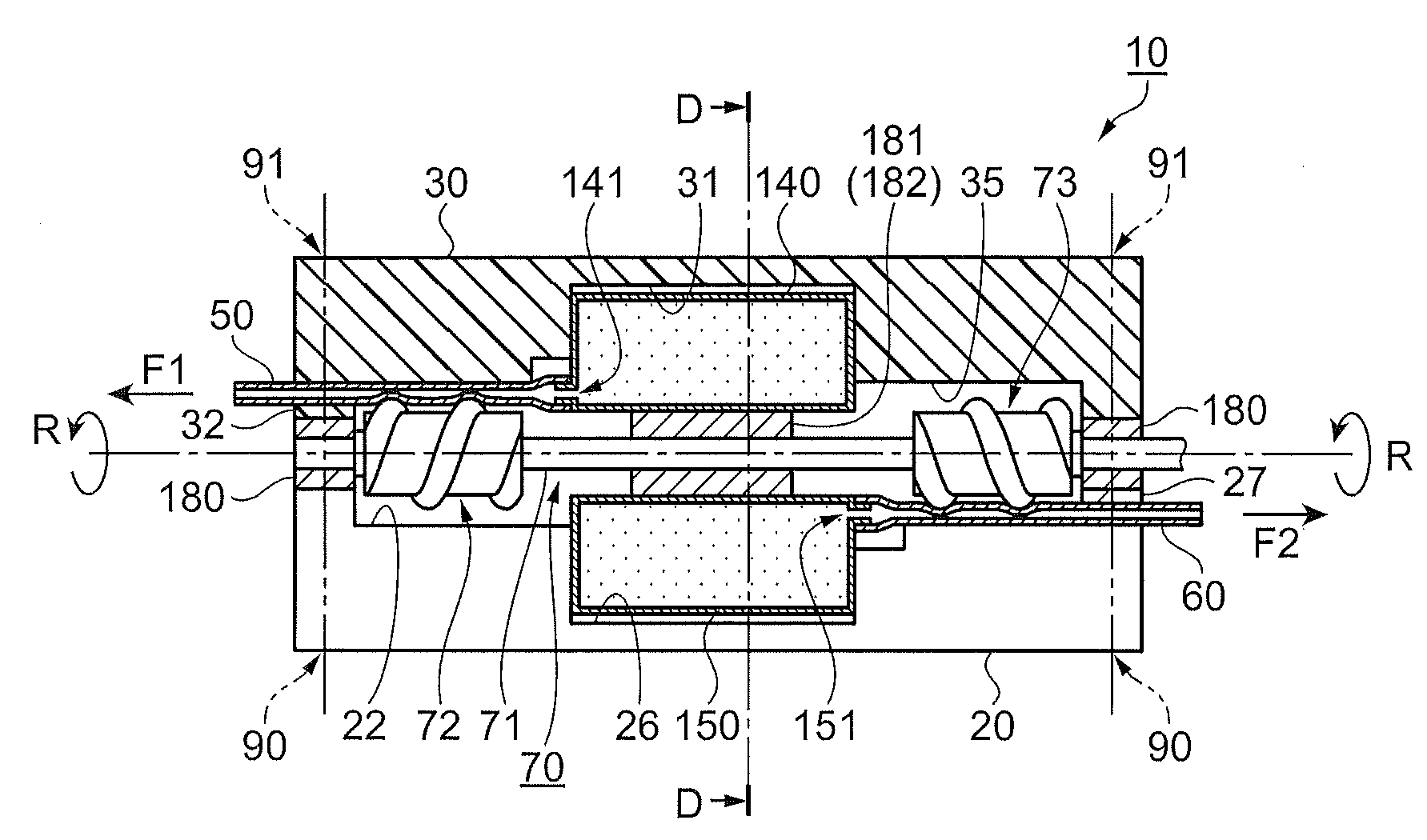

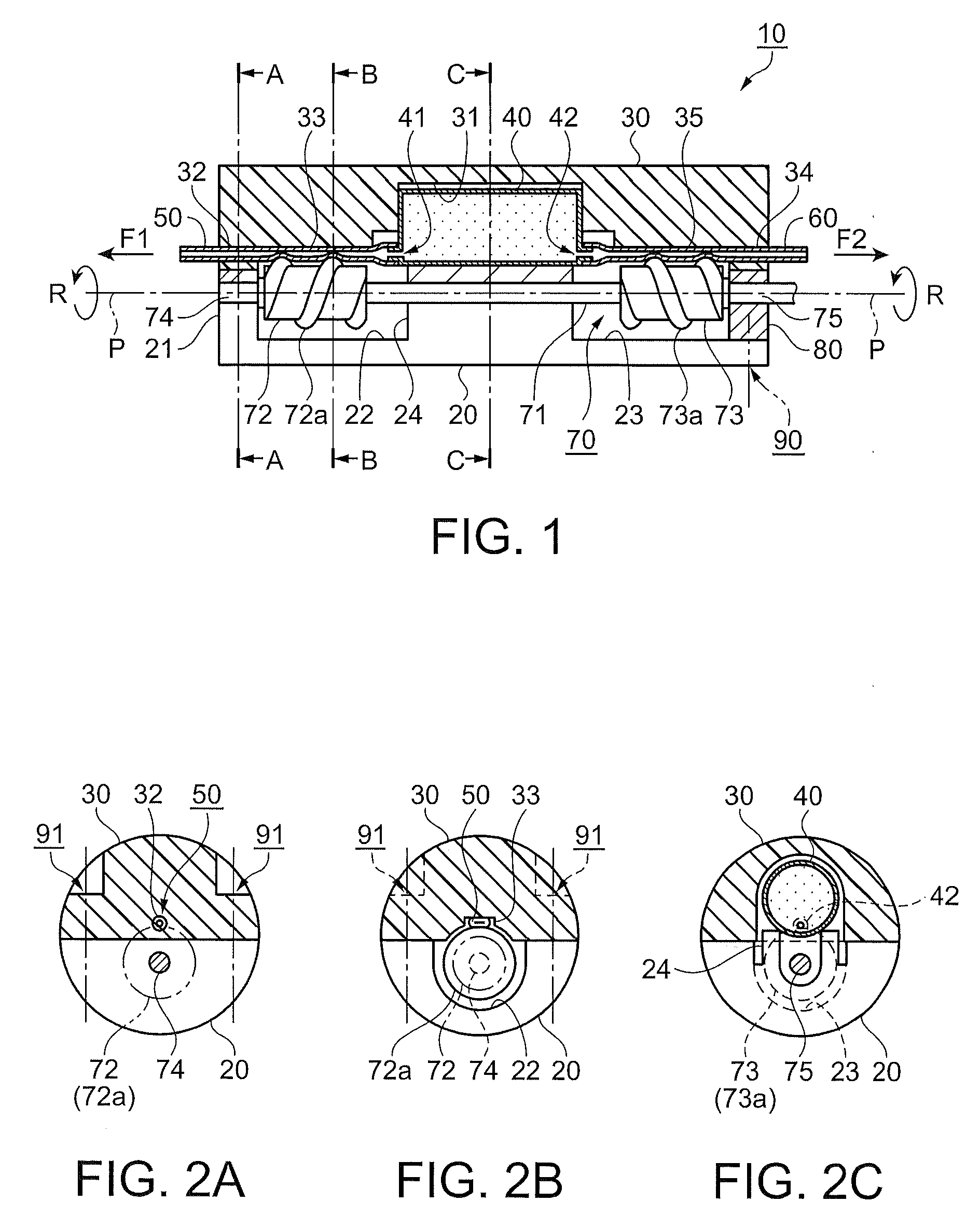

[0067]FIG. 1 is a vertical cross sectional view of a liquid transfer device of a first embodiment, and FIGS. 2A to 2C are horizontal cross sectional views of the liquid transfer device of FIG. 1, i.e., FIG. 2A is a cross sectional view of the device along a line A-A, FIG. 2B is a cross sectional view of FIG. 2A along a line B-B, and FIG. 2C is a cross sectional view of FIG. 2A along a line C-C. In FIGS. 1 to 2C, a liquid transfer device 10 is configured to include a reserver 40 storing therein a liquid, first and second tubes 50 and 60, and a tube depressing member 70. The first tube 50 is made elastic, and is extended in one direction after being linked to the reserver 40. The second tube 60 is also made elastic, and is extended in a direction opposite to that of the first tube 50 after being linked to the reserver 40. The tube depressing member 70 is provided for depressing both the first and second tubes 50 and 60.

[0068]As shown in FIG. 1, at the lower portion of the reserver 40,...

second embodiment

Modified Example of Second Embodiment

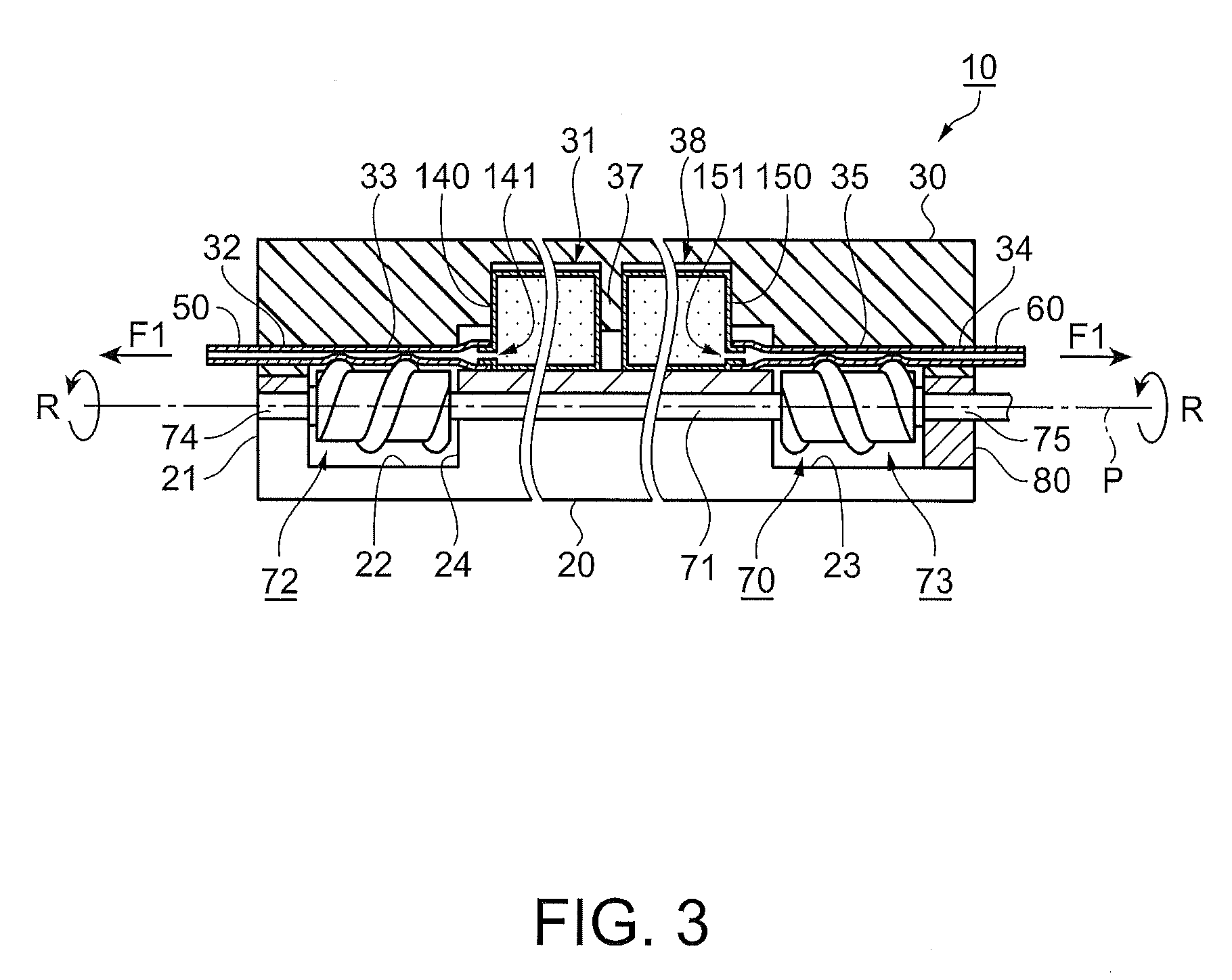

[0102]Described next is a modified example of the second embodiment by referring to the accompanying drawings. Compared with the second embodiment described above, this modified example is characterized in that the first and second reservers 140 and 150 are disposed around the rotation axis P, i.e., the tube depressing member 70. Therefore, any component similar to that of the second embodiment is provided with the same reference numeral, and any difference from the second embodiment is mainly described.

[0103]FIGS. 4A and 4B are each a diagram showing a liquid transfer device in the modified example of the second embodiment, i.e., FIG. 4A is a cross sectional view of the liquid transfer device when viewed from the above, and FIG. 4B is a cross sectional view of FIG. 4A along a line D-D. In FIGS. 4A and 4B, the second reserver 150 is disposed on the side opposite to the first reserver 140 with the tube depressing member 70 disposed therebetween. A...

third embodiment

[0114]Next, a liquid transfer device of a third embodiment is described by referring to the accompanying drawings. The third embodiment is characterized in the configuration of a tube depressing member, and any remaining components are structurally adaptable to those in the first and second embodiments described above. A description is thus given about the tube depressing member by referring to the drawing.

[0115]FIG. 5 is a front view of a tube depressing member of the third embodiment. In FIG. 5, a tube depressing member 170 is configured to include first and second depressing sections 172 and 173, a coupling shaft 171, and support shafts 176 and 177. The coupling shaft 171 serves to couple together the first and second depressing sections 172 and 173, and the support shafts 176 and 177 are respectively provided to end portions of the tube depressing member 170.

[0116]Note here that these components, i.e., the first and second depressing sections 172 and 173, the coupling shaft 171,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com