Molecular electronic device fabrication methods and structures

A device structure and technology of electronic devices, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., to achieve the effect of eliminating short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

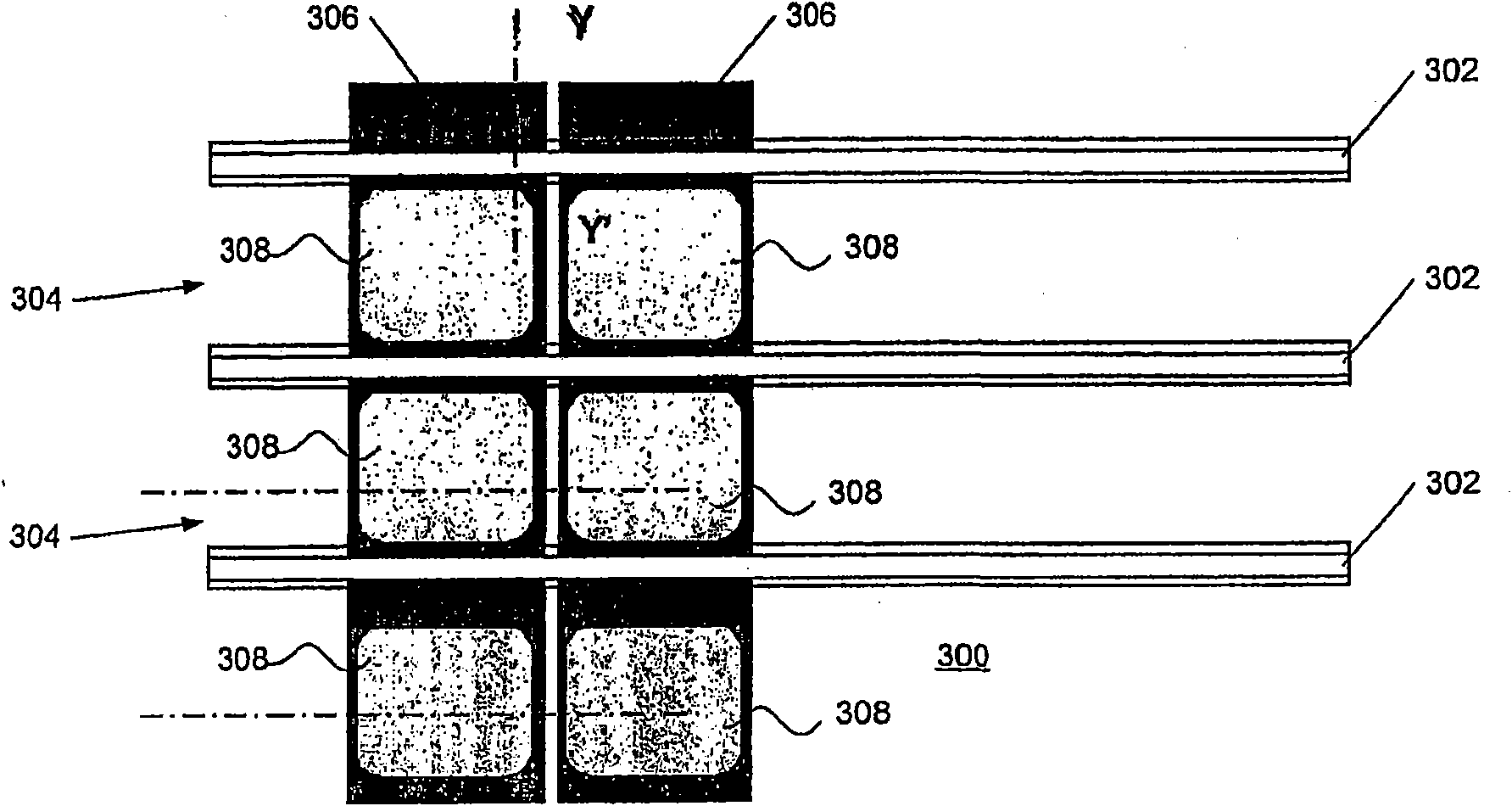

[0060] now refer to Figure 5 , which shows a well bounded on either side by banks that has been filled with a total ink volume V 1 until it overflows above the top of the well (can be measured by microscope). The banks in this figure have a height of about 1.5 μm, are flat on top and are shared by adjacent wells, and have a spacing of x b2 Separates two adjacent ink volumes in adjacent wells. The solution forms a contact angle with the bank material of approximately 35°; this is the angle formed by the surface of the dissolved material and the bank material it contacts. The tapered edge of the bank forms a similar bank angle, eg about 40°, with the plane of the substrate. The dotted lines in this figure represent the contours of the solutions in adjacent wells; it can be seen that careful control of the solution volume is required to avoid the spacing x b2 Reduced to the point where adjacent solutions merge.

[0061] Figure 6 shows that once the solvent has evaporated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com