Droplet deposition apparatus

A deposition device and droplet technology, applied in printing and other directions, can solve problems such as reducing the speed of sprayed droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

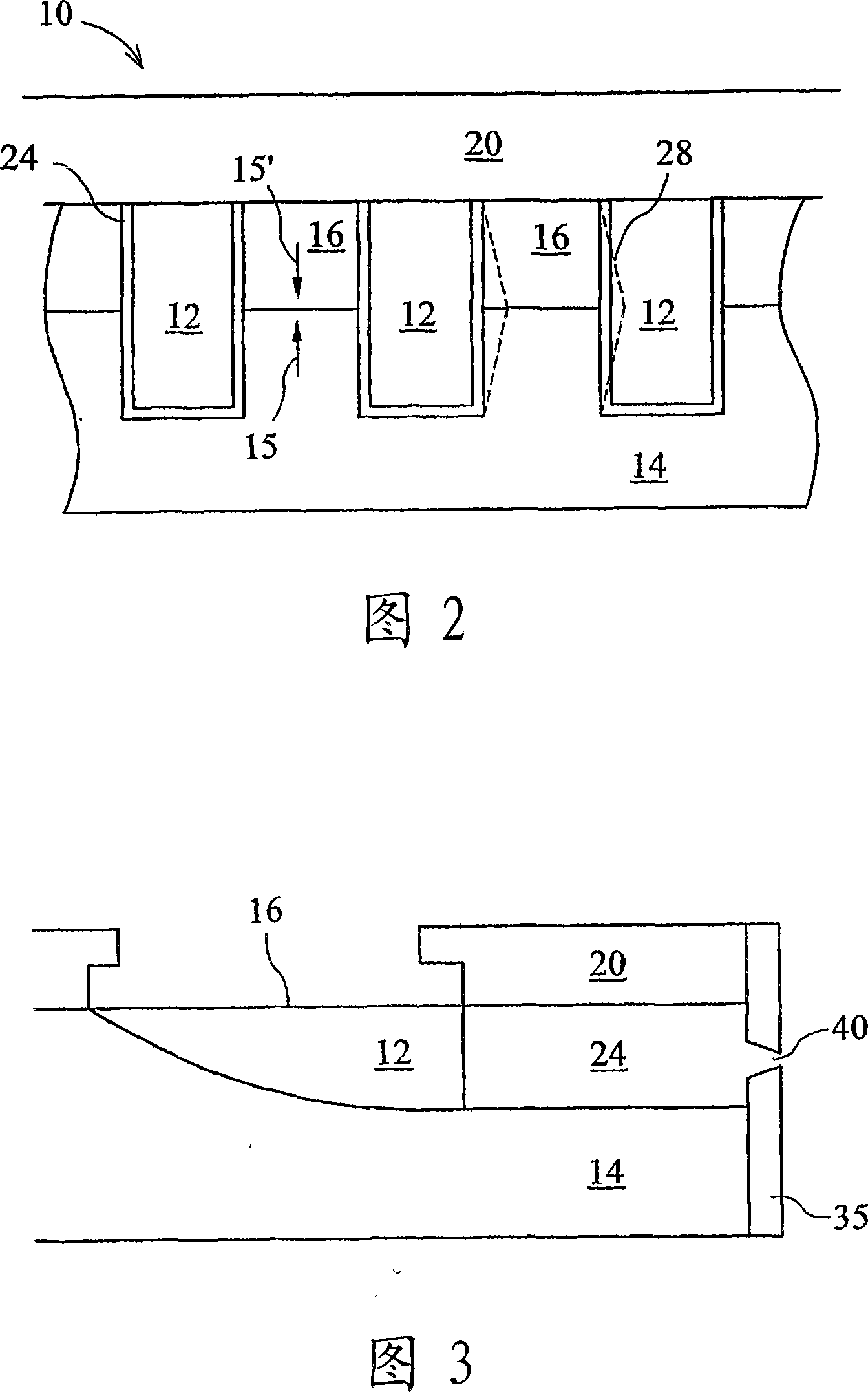

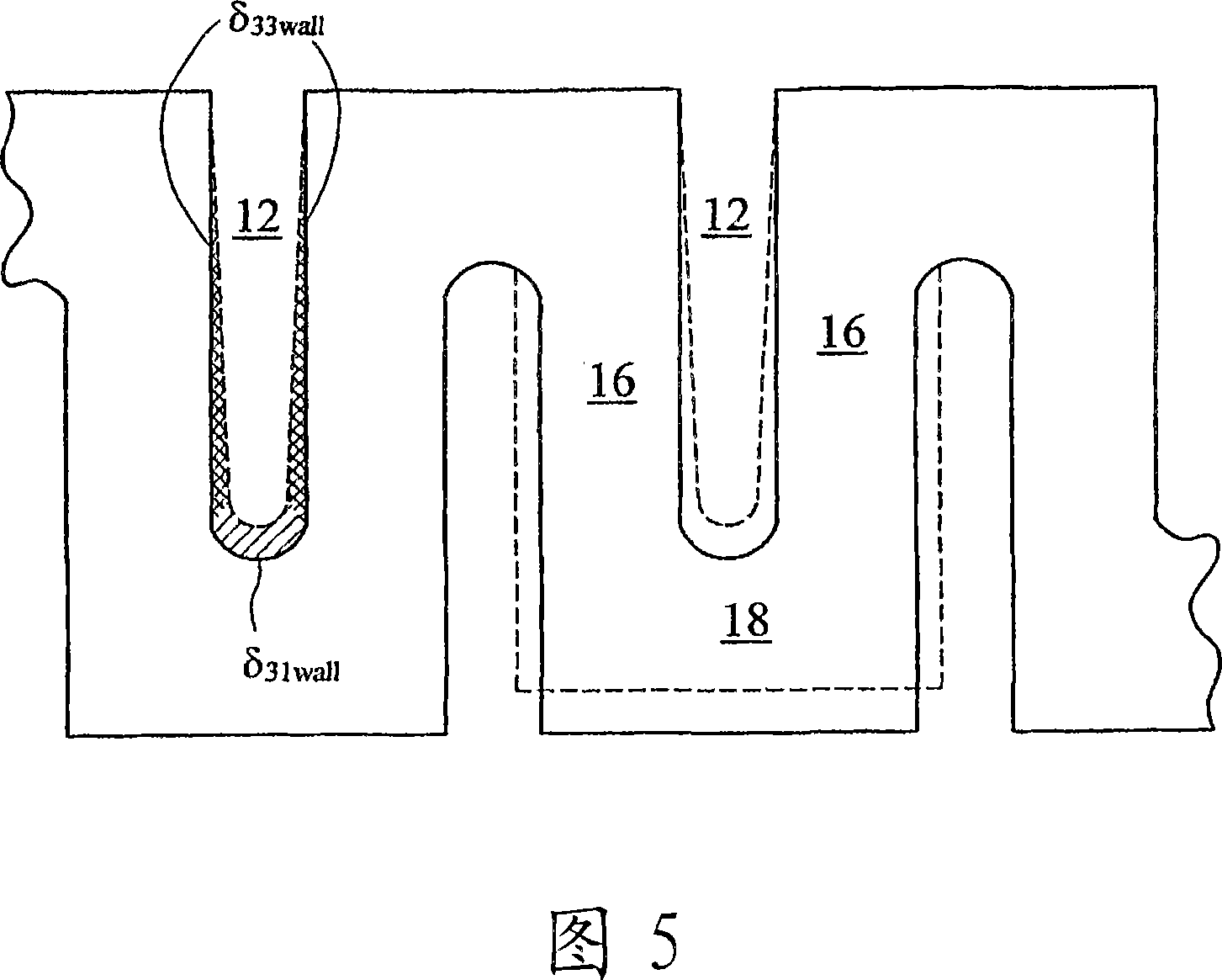

[0035]Referring to Figure 2, the ink jet printhead 10 includes a plurality of parallel ink channels 12 forming an array in which the channels are spaced from each other in an array direction perpendicular to the length of the channels. Said channels are formed at a density of two or more channels per mm in a laminate 14 made of piezoelectric material, suitably PZT, which is polarized in the direction of arrows 15, 15'. , and each channel is defined by sidewalls 16 and a bottom surface, the thickness of the PZT is greater than the depth of the channel. The channel 12 is open at the top and closed in the print head by a top sheet 20 of insulating material thermally mated to the sheet 14 and arranged parallel to the bottom surface of the channel and bonded to the top 22 of the wall 16 . The channels 12 are lined with metallized electrode layers 24 on their sidewalls and bottom surfaces. Thus, when a potential difference of similar magnitude but opposite sign is applied to the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com