Control device and method for achieving wide-range scanning of electron beam and additive manufacturing device

A control device and electron beam technology, which is applied in the field of additive manufacturing, can solve the problems of small defocus and astigmatism, small deflection angle, and inability to realize wide-width scanning of electron beams, achieving high-quality scanning, strong operability, The effect of improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

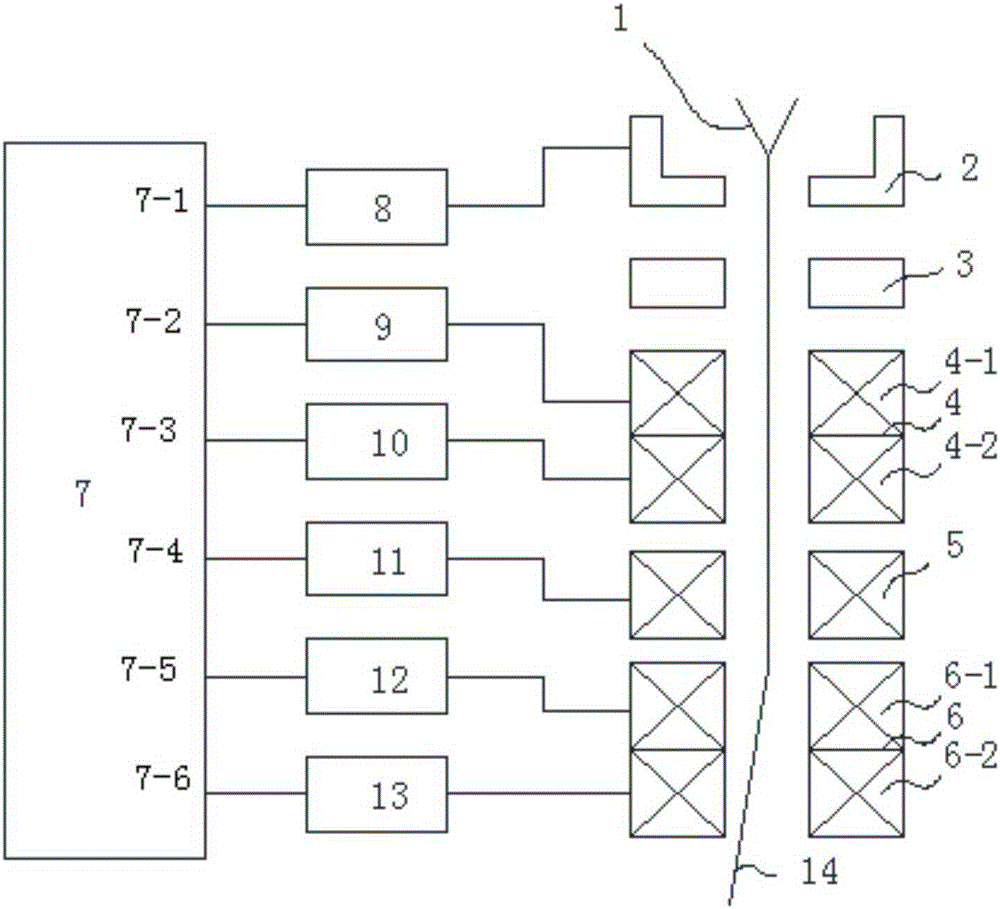

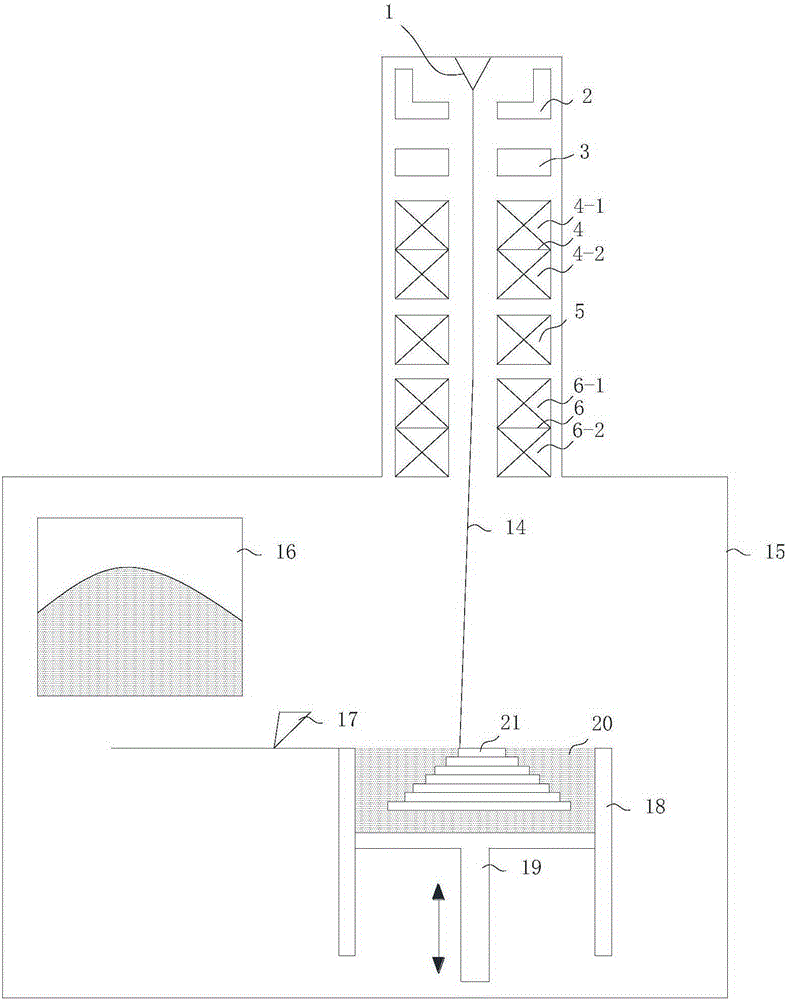

[0054] figure 1 It is a schematic diagram of the control device for electron beam wide scanning according to the present invention.

[0055] Electrons are generated from cathode 1 and pass through grid 2 , anode 3 , destigmatization coil 4 , focusing coil 5 , and deflection yoke 6 in sequence.

[0056] Wherein, electrons are accelerated between the cathode 1 and the anode 3, and the accelerated electrons can melt the metal powder.

[0057] The grid 2 is connected to a high-voltage power supply 8, and the electric field generated between the grid 2 and the cathode 1 can confine electrons. When the voltage on the grid 2 is changed, the electron beam current (ie power) will change accordingly.

[0058] The astigmatism el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com