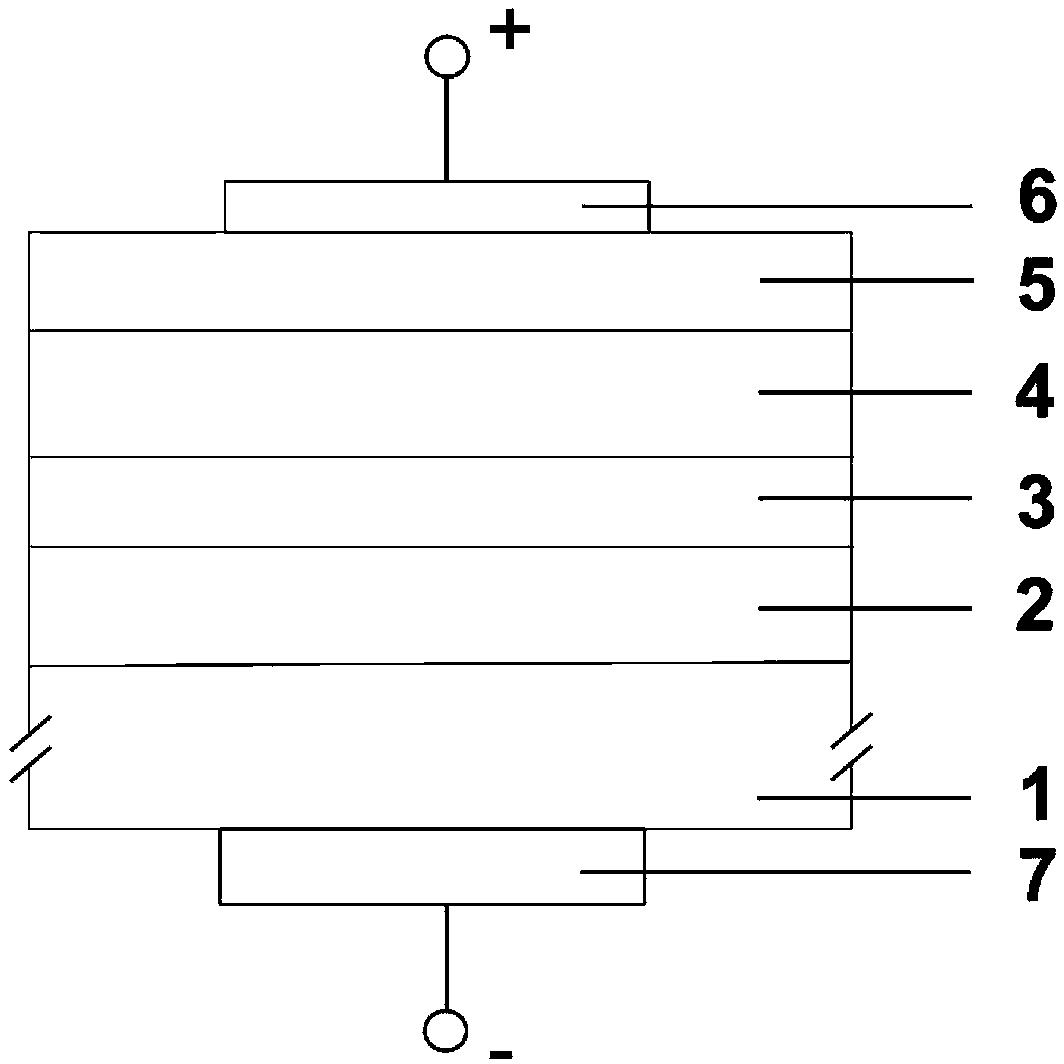

Electrically pumped random laser device based on dual SiO2-ZnO structure and preparation method and application thereof

A random laser and electrical pumping technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem of high threshold current of devices, and achieve the effect of reducing threshold current, improving utilization efficiency, and high optical gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

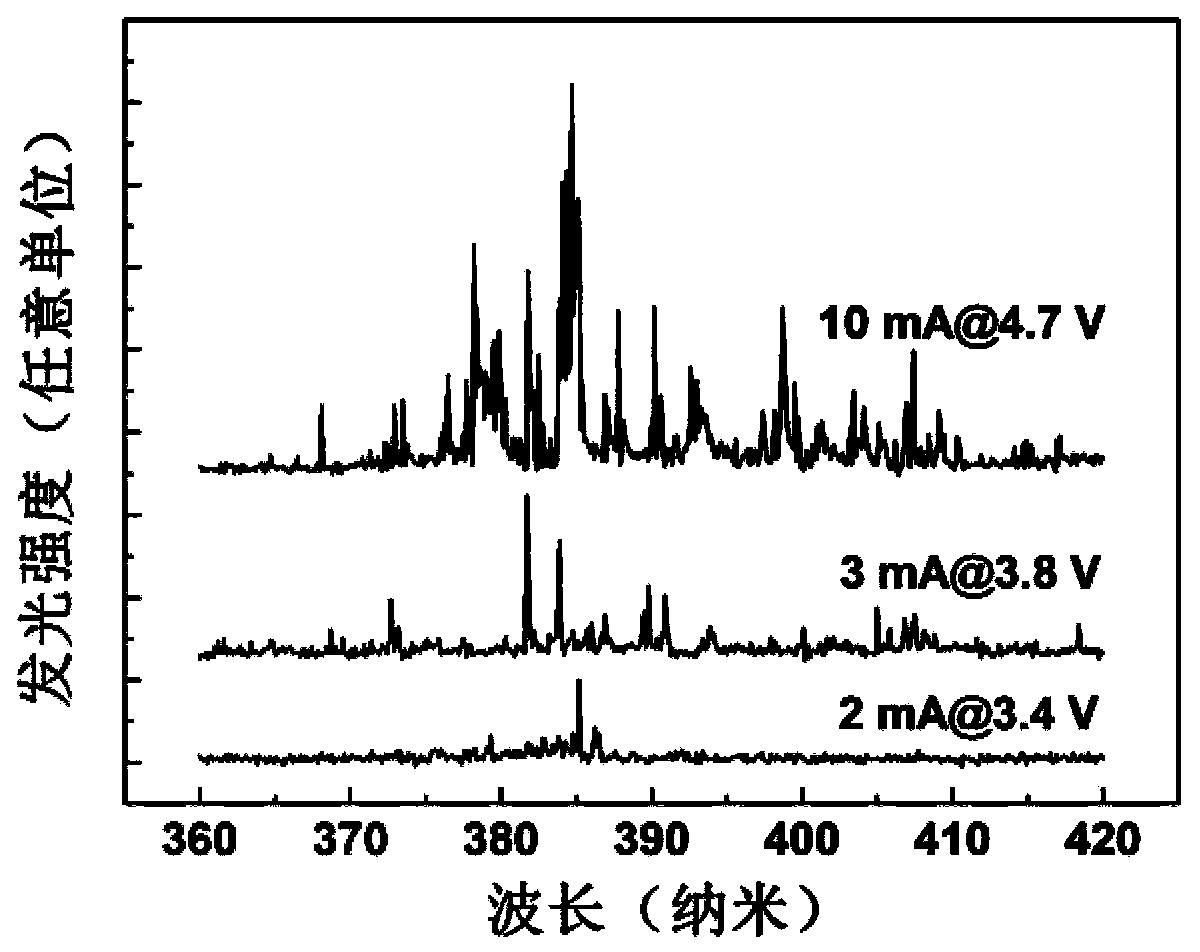

Embodiment 1

[0048] 1) The resistivity is 0.005 ohm? cm, and the size is 15′15 mm 2 , N-type silicon wafer with a thickness of 675 microns as the substrate, after cleaning, put it into the reaction chamber of the radio frequency sputtering device, and deposit the first ZnO film with a thickness of 100 nm on the front side of the silicon substrate by means of radio frequency sputtering , the sputtering condition is: the vacuum degree is 5×10 -3 Pa, using a ceramic ZnO target for sputtering, the substrate temperature is 500 °C, the sputtering power is 100 W, and the 2 Mixed gas with Ar, O 2 The flow ratio to Ar is 1:2, and the working pressure is 4 Pa;

[0049] 2) heat-treating the first ZnO thin film in an oxygen atmosphere at a temperature of 700 °C for 2 hours;

[0050] 3) Deposit the first SiO on the first ZnO film by sol-gel method 2 Thin film, the specific steps are as follows: prepare a precursor solution of tetraethyl orthosilicate (TEOS): ethanol (EtOH) = 1:10 (molar ratio), an...

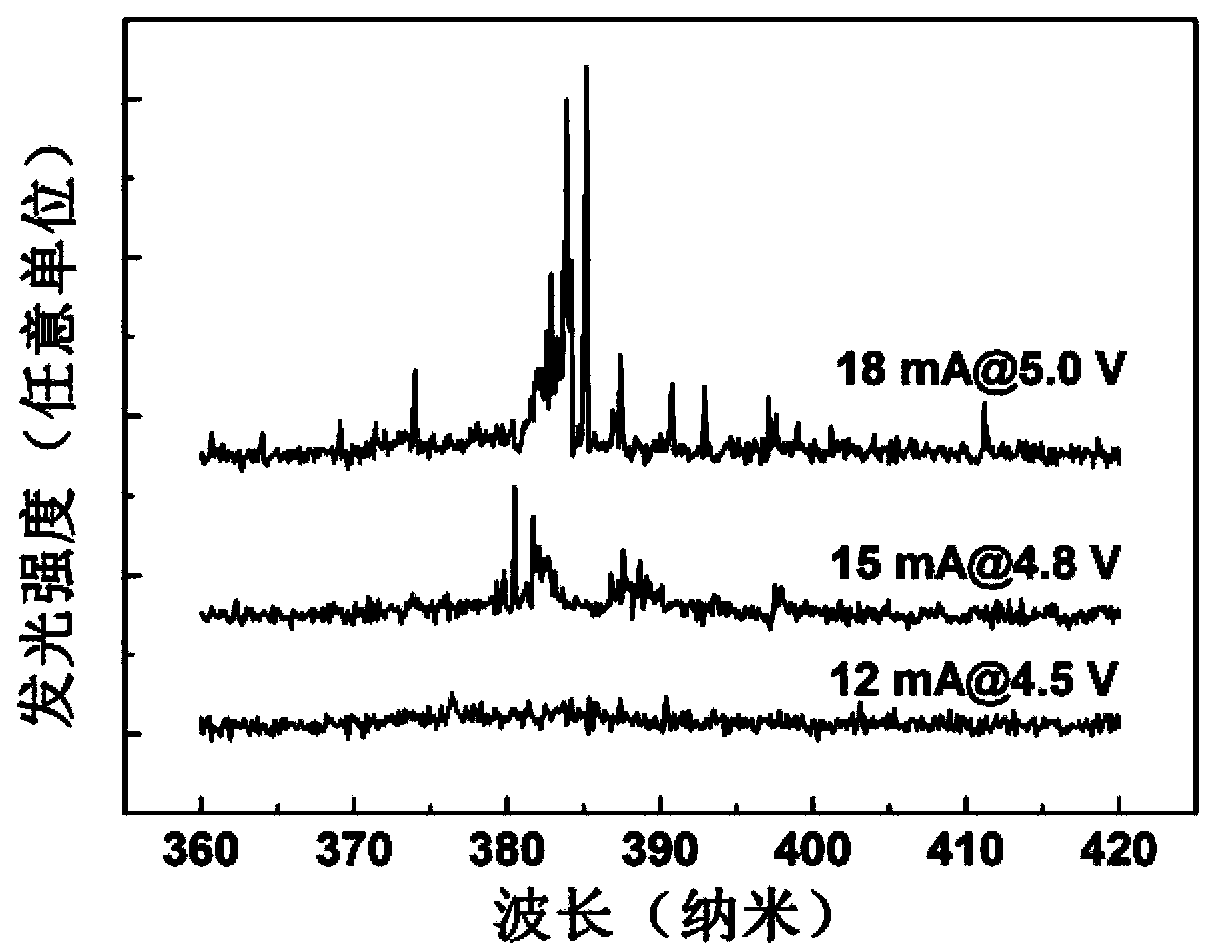

Embodiment 2

[0063] 1) The resistivity is 0.005 ohm? cm, and the size is 15′15 mm 2 , N-type silicon wafer with a thickness of 675 microns as the substrate, after cleaning, put it into the reaction chamber of the radio frequency sputtering device, and deposit the first ZnO film with a thickness of 300 nm on the front of the silicon substrate by means of radio frequency sputtering , the sputtering condition is: the vacuum degree is 5×10 -3 Pa, using a ceramic ZnO target for sputtering, the substrate temperature is 500 °C, the sputtering power is 100 W, and the 2 Mixed gas with Ar, O 2 The flow ratio to Ar is 1:2, and the working pressure is 4 Pa;

[0064] 2) heat-treating the first ZnO thin film in an oxygen atmosphere at a temperature of 600 °C for 1 hour;

[0065] 3) Deposit the first SiO on the first ZnO film by sol-gel method 2 Thin film, the specific steps are as follows: prepare a precursor solution of tetraethyl orthosilicate (TEOS): ethanol (EtOH) = 1:10 (molar ratio), and add ...

Embodiment 3

[0074] 1) The resistivity is 0.005 ohm? cm, and the size is 15′15 mm 2 , N-type silicon wafer with a thickness of 675 microns as the substrate, after cleaning, put it into the reaction chamber of the radio frequency sputtering device, and deposit the first ZnO film with a thickness of 30 nm on the front of the silicon substrate by means of radio frequency sputtering , the sputtering condition is: the vacuum degree is 5×10 -3 Pa, using a ceramic ZnO target for sputtering, the substrate temperature is 500 °C, the sputtering power is 100 W, and the 2 Mixed gas with Ar, O 2 The flow ratio to Ar is 1:2, and the working pressure is 4 Pa;

[0075] 2) heat-treating the first ZnO thin film in an oxygen atmosphere at a temperature of 300 °C for 0.5 hours;

[0076] 3) Deposit the first SiO on the first ZnO film by sol-gel method 2 Thin film, the specific steps are as follows: prepare a precursor solution of tetraethyl orthosilicate (TEOS): ethanol (EtOH) = 1:10 (molar ratio), and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com