A laser beam astigmatism compensation method and laser processing system

A laser processing and laser beam technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as inconsistent line width and depth, affecting the quality of laser processing, etc., to reduce processing costs, improve processing effects, and design The effect of improved consistency of line width and depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

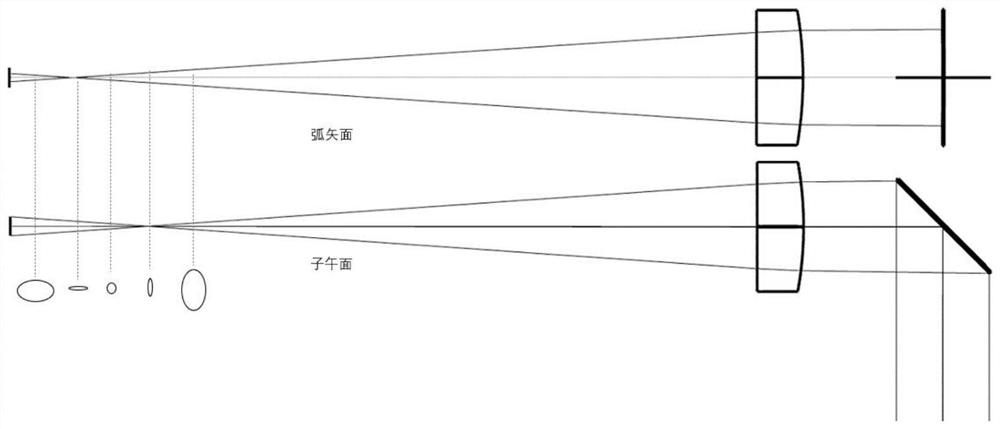

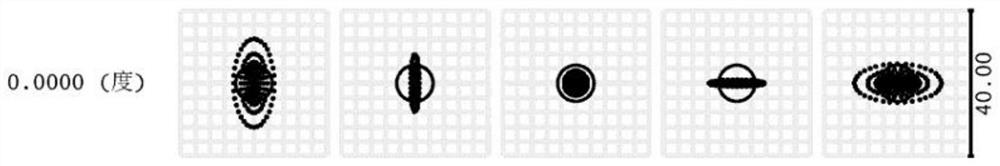

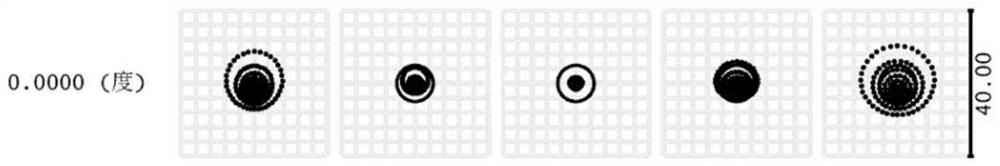

[0036] This embodiment discloses a laser beam astigmatism compensation method, including the following steps:

[0037] An astigmatism compensation device is added to the external optical path of the laser processing system, and the astigmatism is generated after the laser beam passes through the astigmatism compensation device;

[0038] Adjust the rotation angle of the optical elements in the astigmatism compensation device, change the size and direction of the astigmatism generated by the astigmatism compensation device, so that the astigmatism generated by the astigmatism compensation device is equal to the astigmatism of the original laser processing system and opposite in direction. The astigmatism of the whole laser processing system is reversely compensated.

[0039] The patent can manually adjust the rotation angle of the astigmatism compensation optical element, and can also automatically adjust the rotation angle of the astigmatism compensation optical element. In th...

Embodiment 2

[0061] Figure 8 What is shown is a schematic diagram of a common laser processing optical path application debugging. This embodiment discloses a laser processing system, including a laser 1, a vibrating mirror 3, a field lens 4, and an astigmatism compensation device 5. The laser 1 is used for generate and emit laser beams;

[0062] The vibrating mirror 3 is used to receive the laser beam, and the motor drives the mirror to swing to change the processing path of the laser beam;

[0063] The field lens 4 is used to focus the laser beam passing through the galvanometer onto the surface of the sample to be processed for processing;

[0064] The astigmatism compensation device 5 is located on the optical path before or after focusing, and the astigmatism compensation device is used to generate the reverse astigmatism equivalent to the astigmatism of the original laser processing system, and compensate the laser and laser in the laser processing system. Astigmatism formed compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com