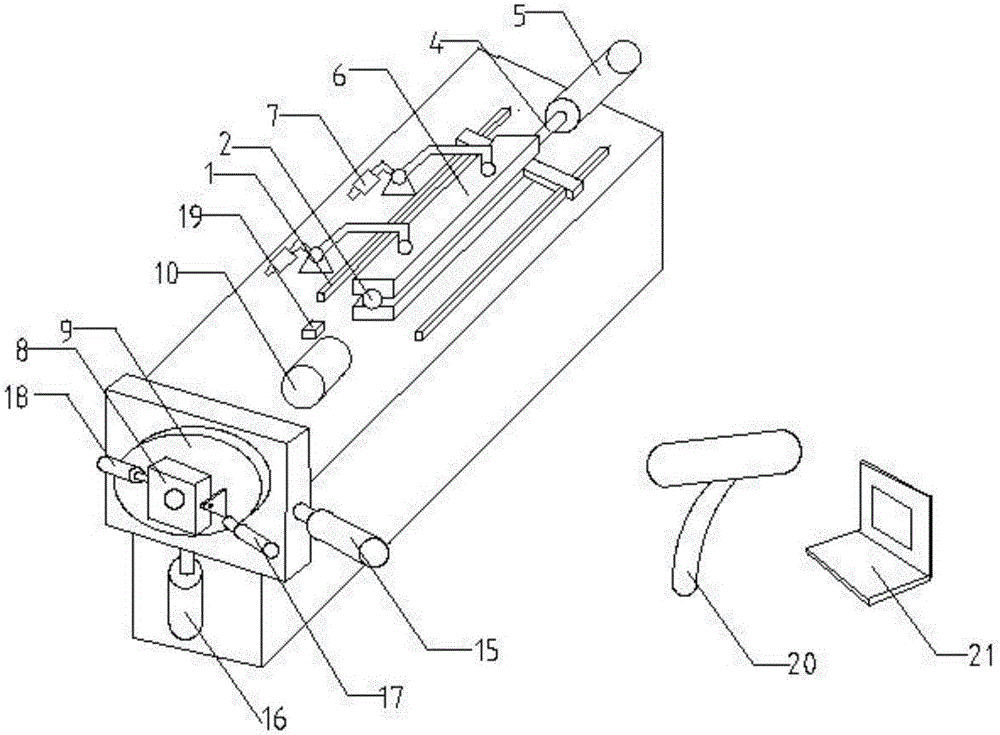

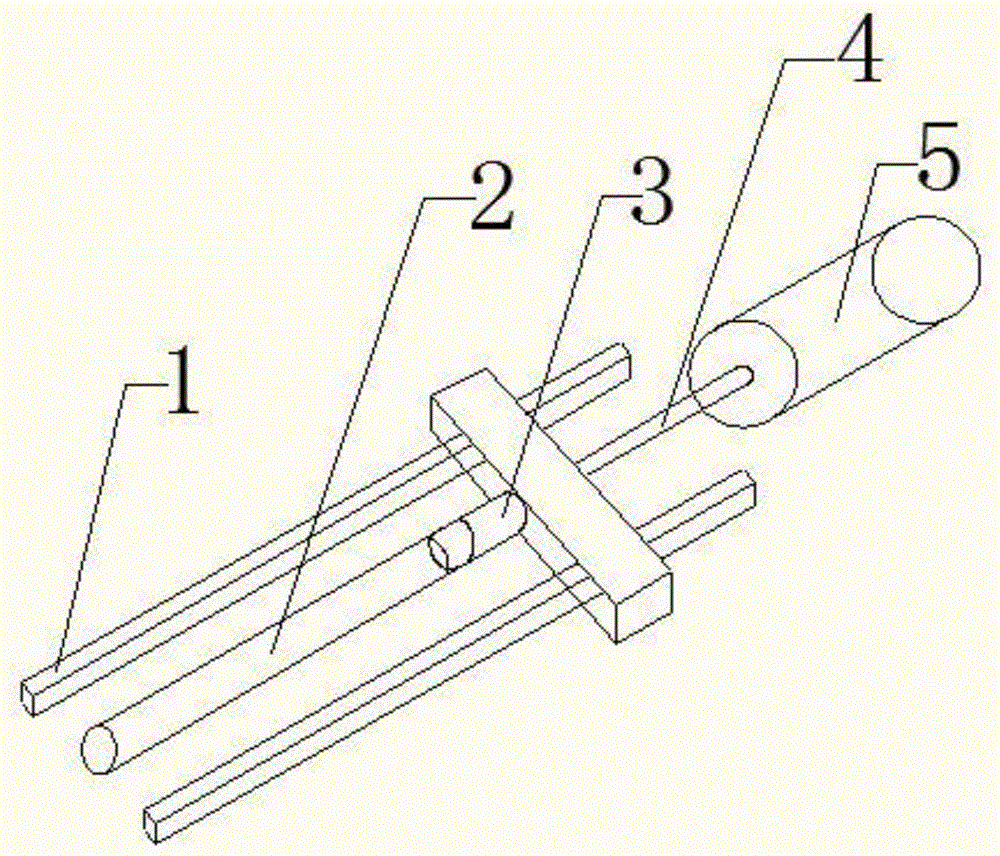

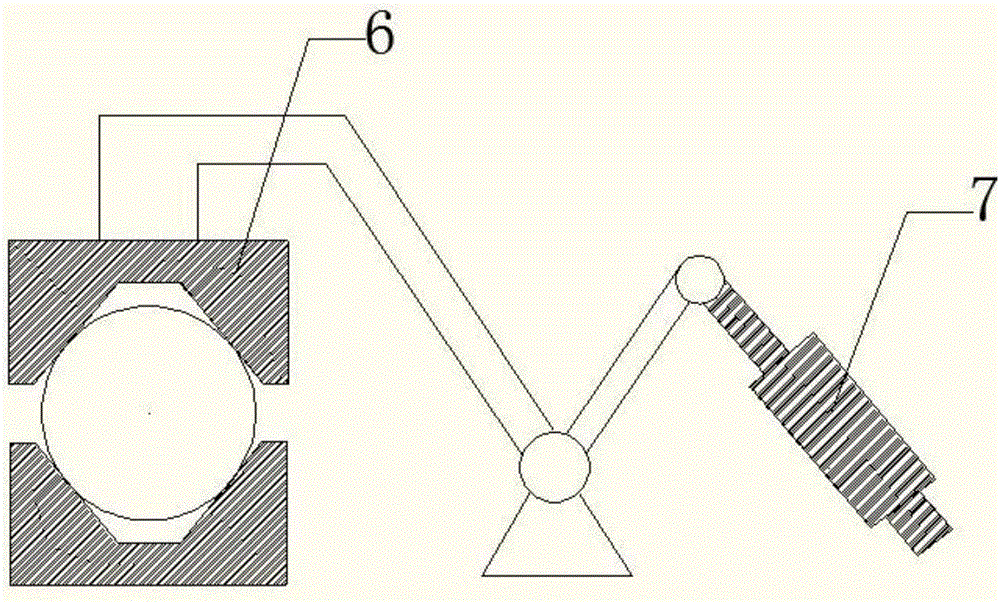

3D free-bending forming method and five-axis free bending device for metal pipes

A metal pipe and bending technology, applied in the field of metal pipe 3D free bending forming method and five-axis free bending equipment, can solve the problems of uneven surface of welded pipe bend, reduced pipe strength, large fluid resistance, etc. Distortion, good forming quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1) Use a 3D scanning measuring instrument to perform reverse scanning on the target "L"-shaped elbow formed by a semi-automatic method to obtain its three-dimensional geometric model;

[0061] 2) In the reverse scanning and measuring workstation, the three-dimensional geometric model is analyzed to obtain the size parameters of the "L"-shaped elbow: the outer diameter is 20mm, the length of the straight section at both ends is 200mm, and the radius of the arc section is 87.85mm , The "L" shaped elbow is carried out as follows Figure 8 segment shown. Take the pipe axial feeding speed u z =10mm / s, the distance A from the bending die to the center of the bending die base is 30mm. Convert this size parameter into the actual bending process parameters of each small segment, as shown below, where u x is the movement speed of the bending die in x direction, u y is the movement speed of the bending die in the y direction, w is the rotational angular velocity of the bendi...

Embodiment 2

[0081] 1) Use a 3D scanning measuring instrument to perform reverse scanning on the target "U"-shaped elbow formed by a semi-automatic method to obtain its three-dimensional geometric model;

[0082] 2) In the reverse scanning and measuring workstation, the three-dimensional geometric model is analyzed to obtain the size parameters of the "U"-shaped elbow: the outer diameter is 15mm, the length of the straight section at both ends and the bottom is 200mm, and the radius of the arc section is 63.75mm, two arc segments Both are 90°. The "U" bend is carried out as follows Figure 9 segment shown. Take the pipe axial feeding speed u z =10mm / s, the distance from the bending die to the center of the bending die base is 22.5mm. The conversion of this size parameter into actual bending process parameters is as follows, where u x is the movement speed of the bending die in x direction, u y is the movement speed of the bending die in the y direction, w is the rotational angular v...

Embodiment 3

[0111] 1) Use a 3D scanning measuring instrument to perform reverse scanning on the target "S"-shaped elbow formed by a semi-automatic method to obtain its three-dimensional geometric model;

[0112] 2) In the reverse scanning and measuring workstation, the three-dimensional geometric model is analyzed to obtain the size parameters of the "S"-shaped elbow: the outer diameter is 15mm, the radius of the two semicircles is 100mm, and the radius of the two arc segments is The values are all 90°. The "S" bend is carried out as follows Figure 10 segment shown. Take the pipe axial feeding speed u z =10mm / s, the distance from the bending die to the center of the bending die base is 22.5mm. The conversion of this size parameter into actual bending process parameters is as follows, where u x is the movement speed of the bending die in x direction, u y is the movement speed of the bending die in the y direction, w is the rotational angular velocity of the bending die around its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com