Sealing structure of wire inlet hole and explosion-proof lamp

A technology of sealing structure and wire inlet, which is applied in the field of explosion-proof lamps, can solve the problems of long curing time, complicated operation, unstable sealing, etc., and achieve the effect of simple replacement, simple operation and reliable sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

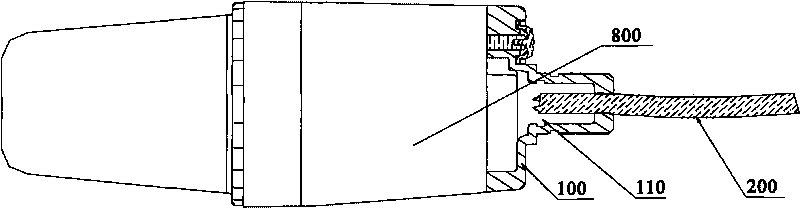

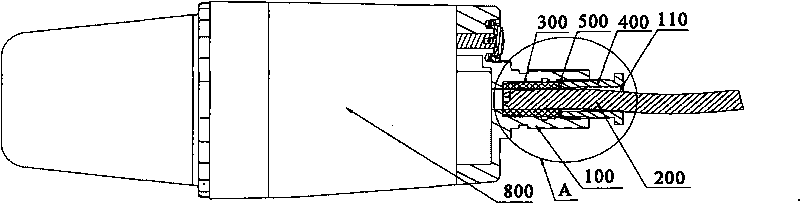

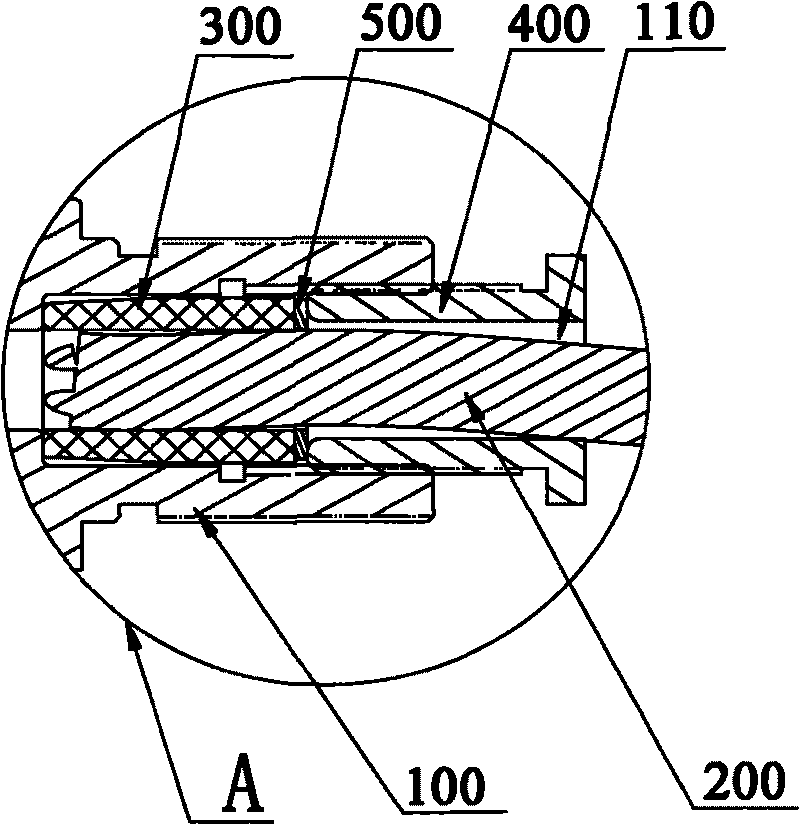

[0021] In this preferred embodiment, the explosion-proof lamp of the present invention includes a lamp body 800 and a lamp canister 100. A wire inlet hole 110 is opened on one side of the lamp canister 100, and the cable 200 enters the explosion-proof lamp body 800 through the wire inlet hole 110. connected to its internal wiring, such as figure 2 shown. In order to enhance the safety of the explosion-proof lamp, it is necessary to seal the radial gap between the wire inlet hole 110 and the cable 200 to prevent the outside gas and water from entering the lamp body and bring about potential safety hazards. Therefore, the wire inlet hole sealing structure adopted by the explosion-proof lamp of this embodiment is a preferred embodiment of the wire inlet hole sealing structure of the present invention, which includes a filler 300, a gasket 500 and a pressing member. The tightening piece is a compression nut 400.

[0022] image 3 for figure 2 A magnified view of part A of . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com