Engine timing system assembling tool

A timing system and assembly tooling technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of changing the engine and poor versatility, and achieve the effects of shortened assembly hours, strong versatility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

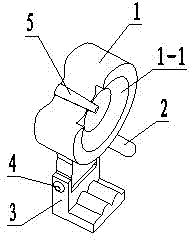

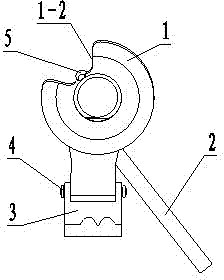

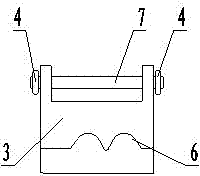

[0029] See Figure 1, Figure 2, image 3 , the present invention is composed of a camshaft timing sprocket adjustment device and a crankshaft timing sprocket adjustment device. The camshaft timing sprocket adjustment device includes a camshaft timing sprocket adjustment device body 1, a locking seat 3, a positioning Pin 5 and pull rod 2, the body 1 of the camshaft timing sprocket adjustment device is a disc-shaped structure, and a positioning pin avoidance groove 1-2 is provided on its outer circular surface, and the positioning pin 5 is installed in the positioning pin avoidance groove 1-2, the working end surface of the camshaft timing sprocket adjustment device body is provided with a stepped concave structure 1-1, and the stepped groove structure 1-1 is matched with the camshaft timing sprocket hub 28, One end of the pull rod 2 is fixedly assembled with the camshaft timing sprocket adjusting device body 1 , and the locking seat 3 is hinged with the camshaft timing sprocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com