Backboard structure of backlight module

A backlight module and backplane technology, applied in optics, nonlinear optics, lighting devices, etc., can solve the problems of complexity, high process and material cost, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to save costs, the length of the drive circuit board has been shortened. Following the trend, the distance between the printed circuit board and the iron frame needs to be shortened, so the distance between the printed circuit board and the plastic frame is relatively shortened;

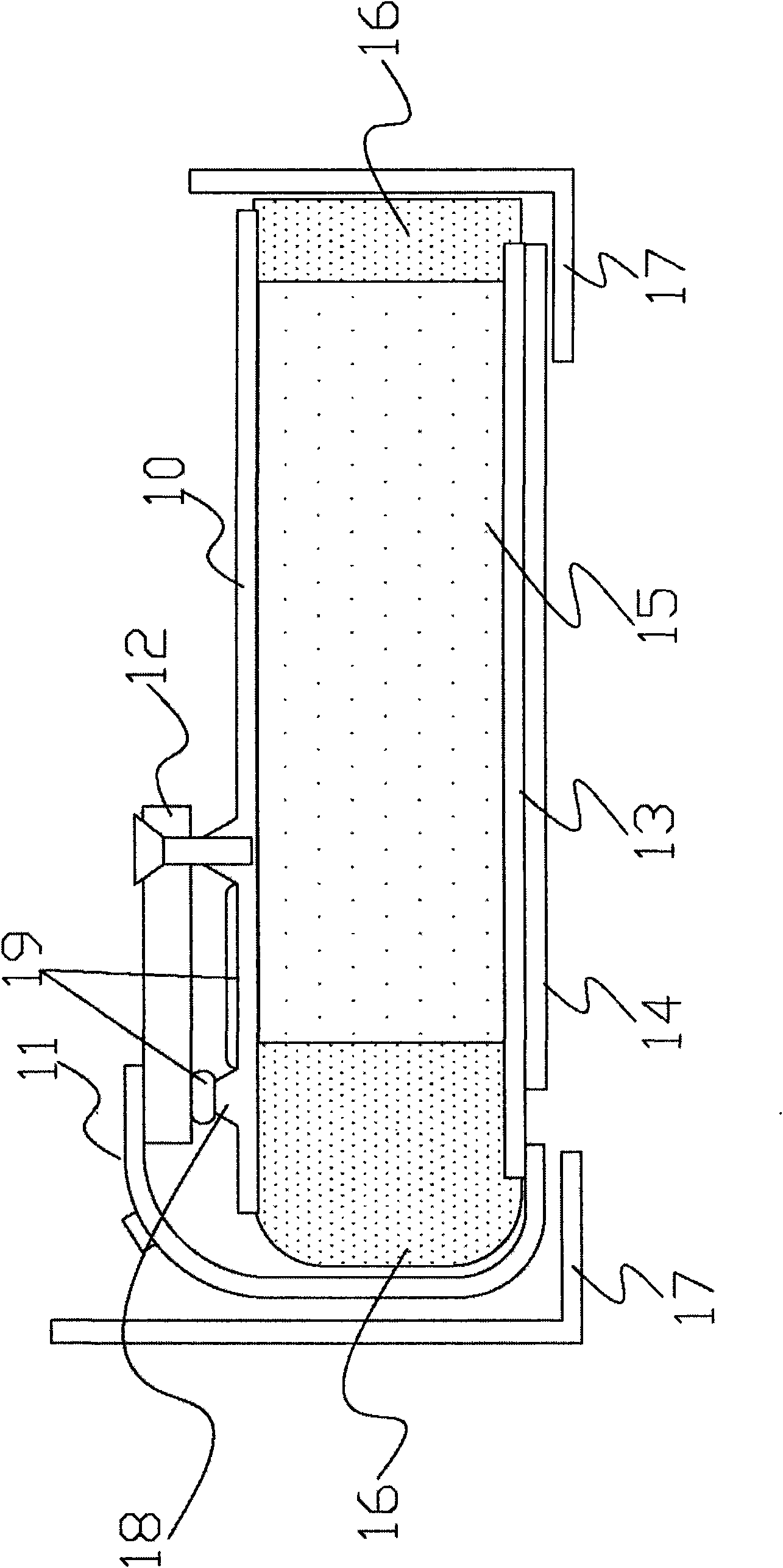

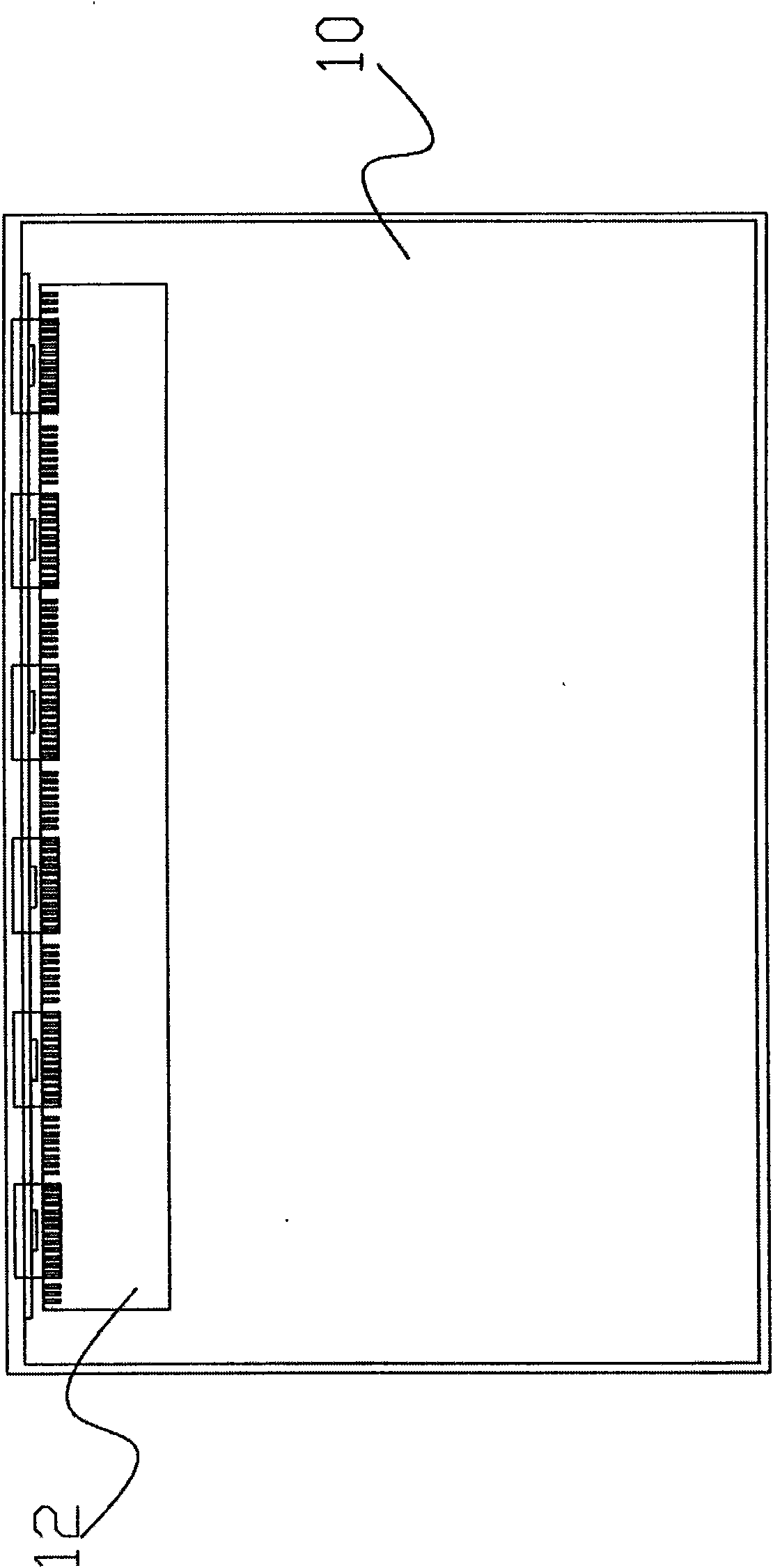

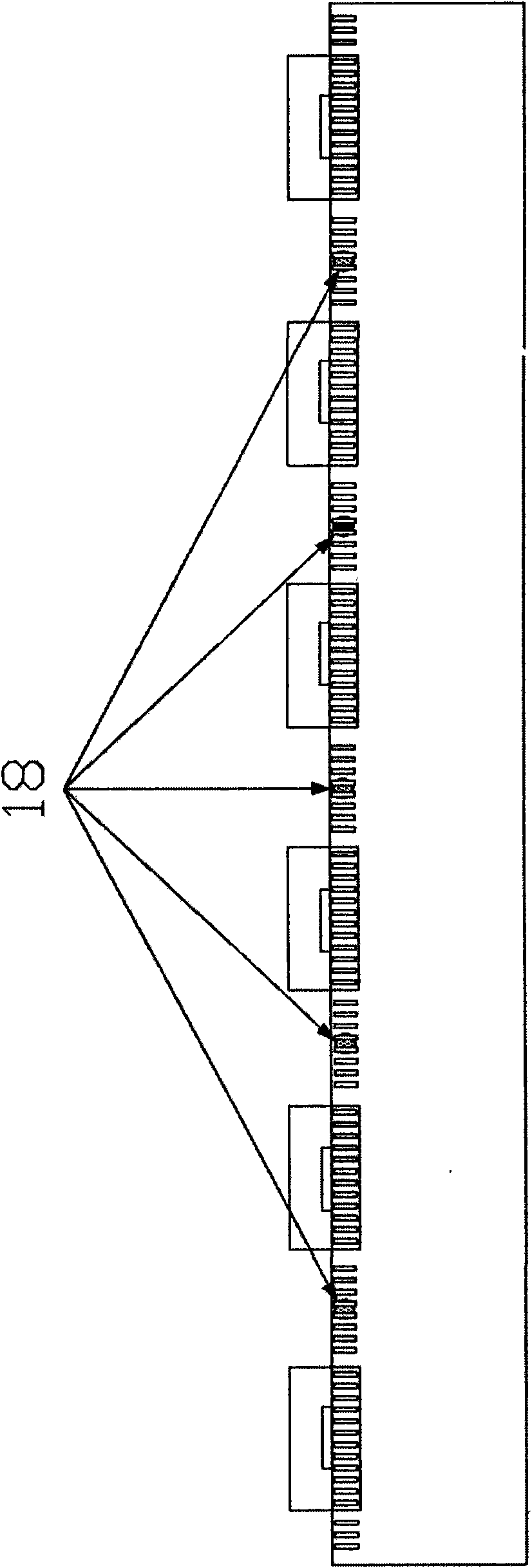

[0021] The present invention proposes a backplane structure of a backlight module, please refer to Figure 4 As shown, the backplane structure 20 of the backlight module includes a frame 21. In this embodiment, the frame 21 is an iron frame as an example for illustration; The back plate 22 has at least one through positioning hole 23 and at least one positioning portion 231, wherein the positioning hole 23 can be in the shape of a square or a circle, and this embodiment uses a circle as an example for illustration, and the positioning portion 231 is a screw hole; a drive circuit board 24, this drive circuit board 24 has an integrated circuit control chip (IC) 241 and a printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com