Touch display device

A touch display device and touch sensing technology, applied in static indicators, instruments, computing, etc., can solve problems such as difficulty in conforming to thin shape, cumbersome assembly process, and increased assembly thickness, so as to reduce manufacturing costs and finished products Thickness, reduced packaging and shipping costs, and reduced assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms used are illustrative and not limiting of the invention.

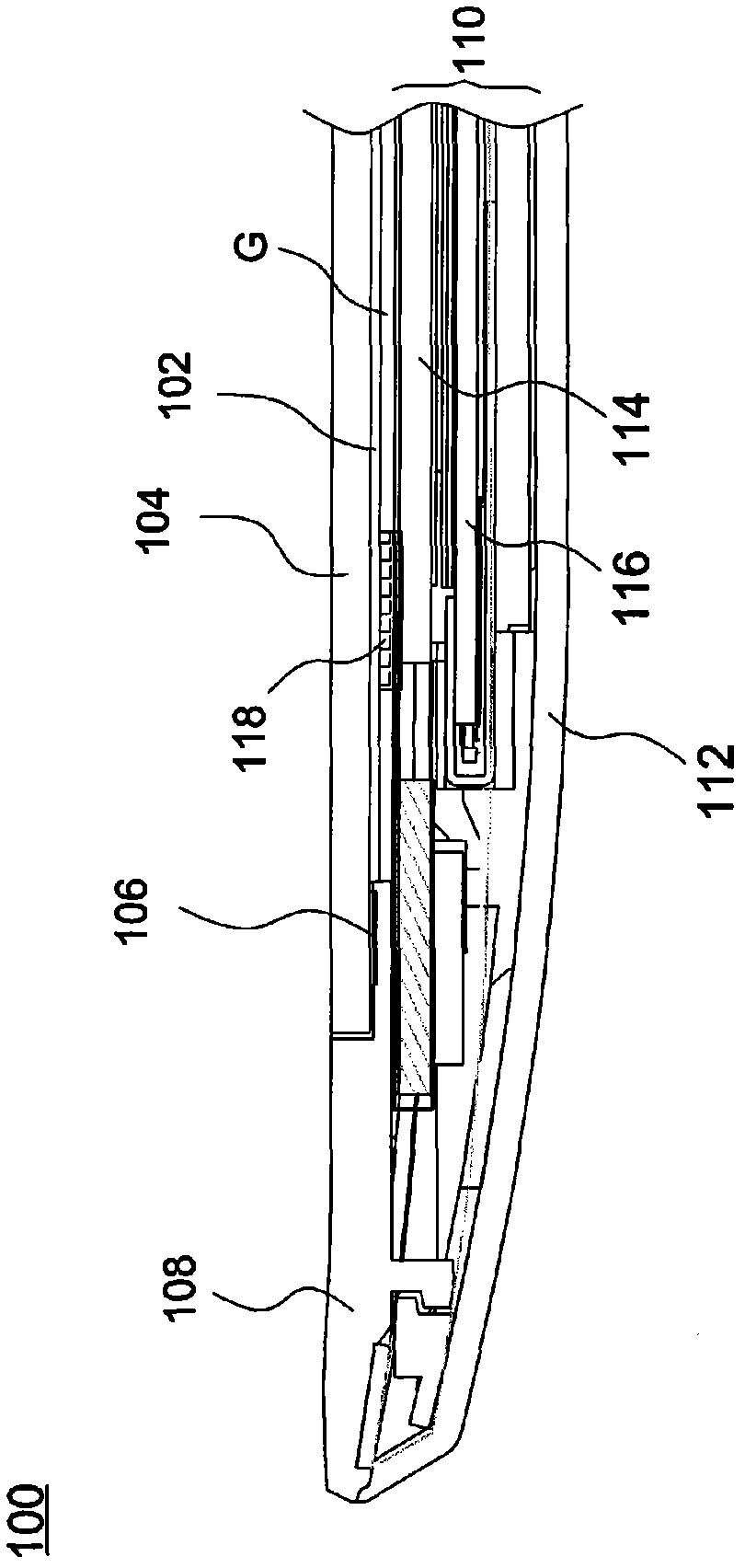

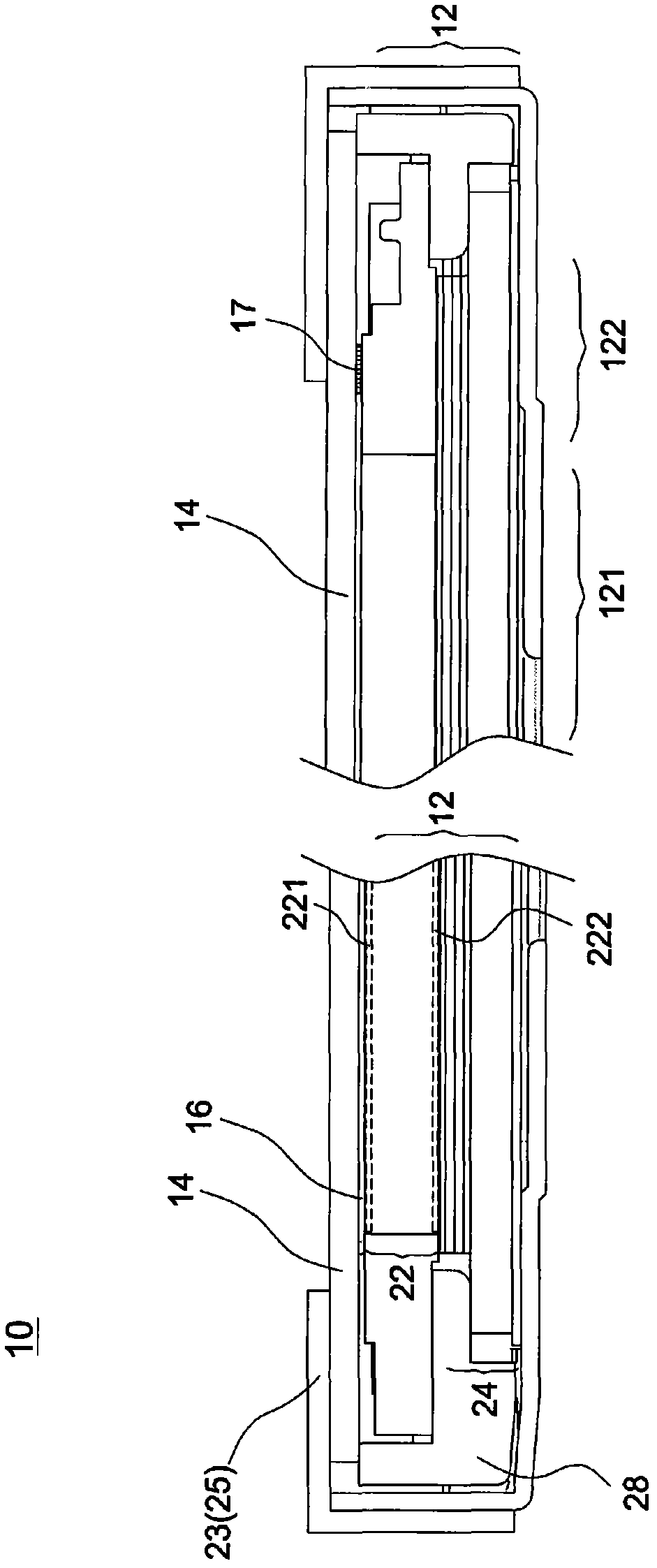

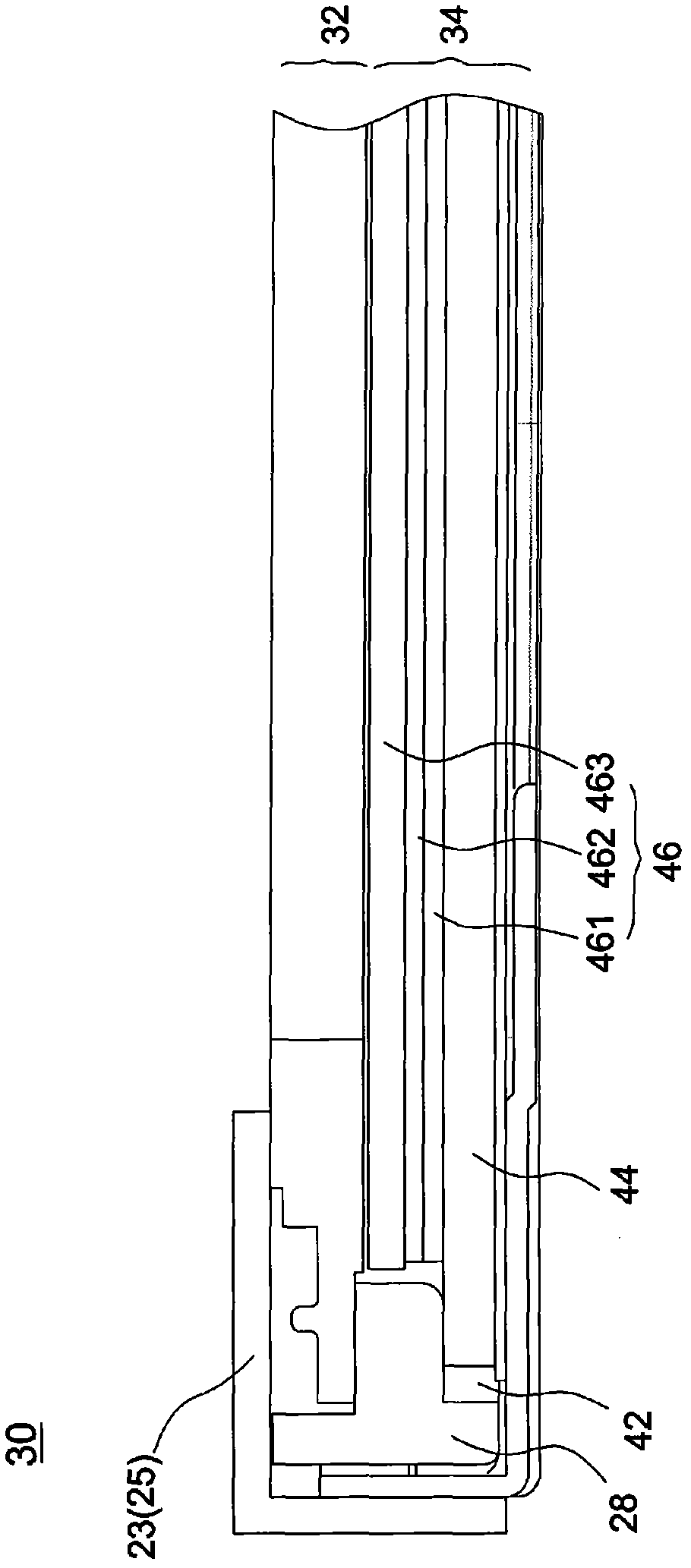

[0065] Such as figure 2As shown, the touch display device 10 includes a liquid crystal display module 12 and a touch sensing element 14 . The liquid crystal display module 12 may include, for example, a liquid crystal panel 22 and a backlight module 24 disposed on one side of the liquid crystal panel 22 . The liquid crystal display module 12 includes a visible area 121 and a non-visible area 122 . The touch sensing element 14 is placed on the liquid crystal display module 12 and attached to the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com