Camera module

A camera module and lens assembly technology, applied in the field of photography, can solve the problems of reducing production efficiency, wasting man-hours, increasing the production cost of electronic devices, etc., and achieve the effect of saving production costs and reducing assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

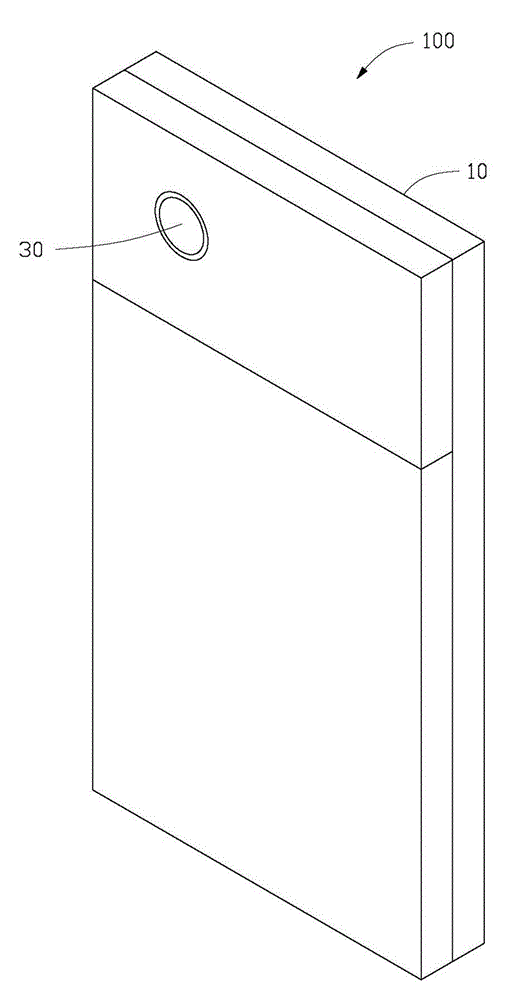

[0027] see figure 1 , the embodiment of the present invention provides an electronic device 100 , which includes a casing 10 and a camera module 30 housed and installed in the casing 10 . In this embodiment, the electronic device 100 is a mobile phone, and it can be understood that the electronic device 100 may also be other electronic devices, such as a tablet computer.

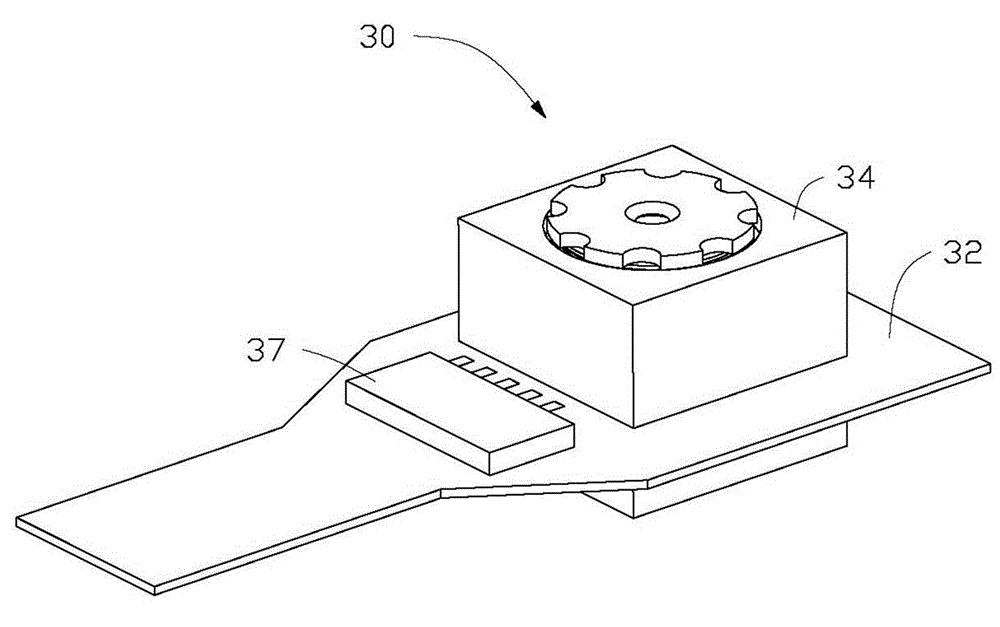

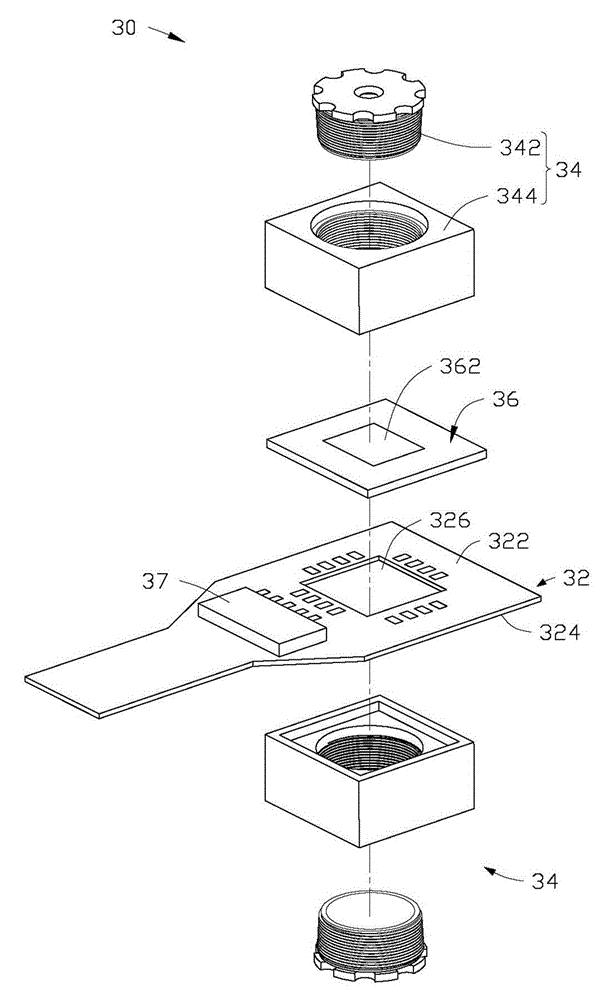

[0028] Please also see Figure 2 to Figure 3 , the first embodiment of the present invention provides a camera module 30 , which includes a circuit board 32 , a lens assembly 34 electrically connected to the circuit board 32 , a double-sided image sensor 36 and a connector 37 . The circuit board 32 is used to connect with the main board (not shown) of the electronic device 100 . There are two lens assemblies 34 , and the two lens assemblies 34 are respectively electrically connected to the circuit board 32 , and serve as a front camera and a rear camera of the electronic device 100 respectively. The doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com