New method for assembling motor stator core

A technology of motor stator and new method, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of difficulty in controlling the straightness of the inner diameter of the stator core, increasing the eddy current loss of the stator core, and increasing the number of grinding times, so as to achieve small gaps and reduce assembly The effect of less man-hours and grinding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

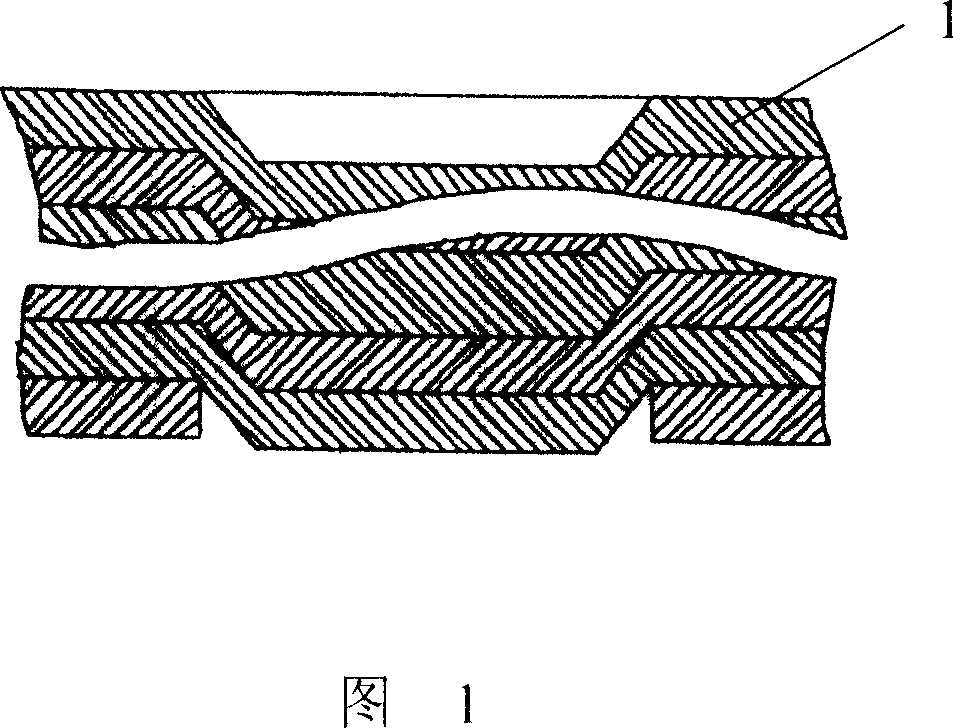

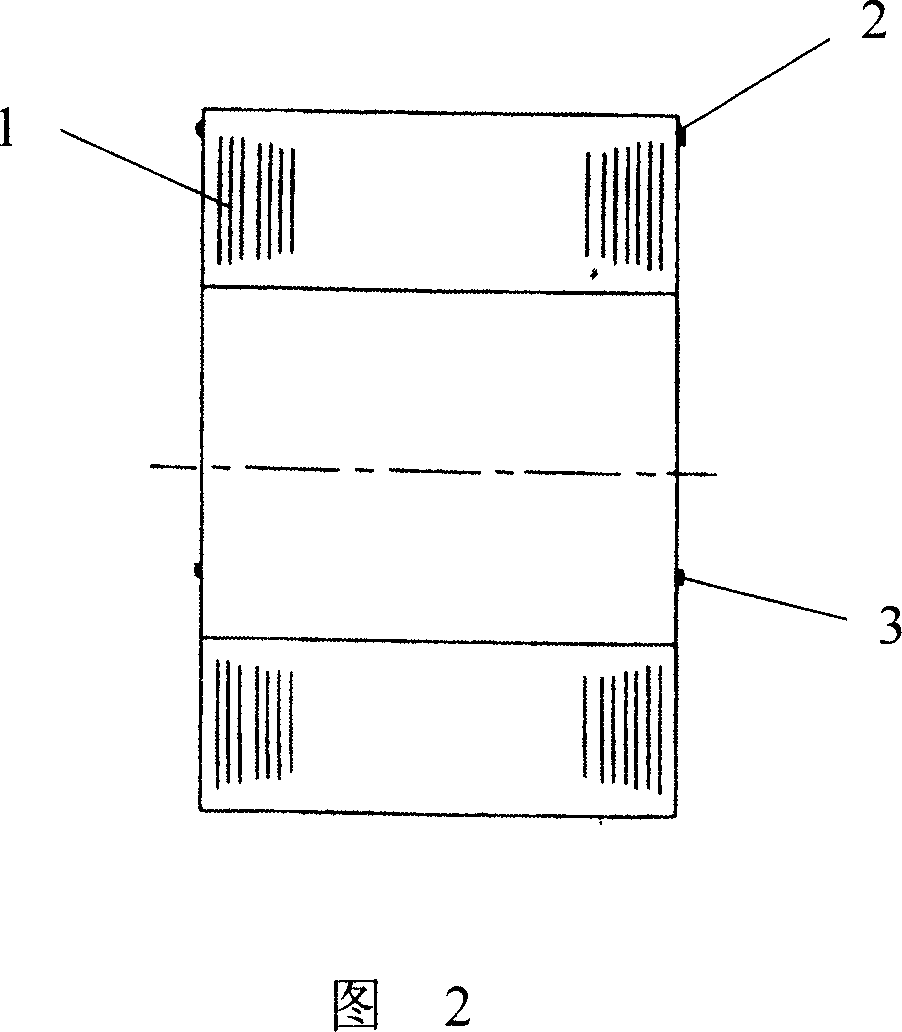

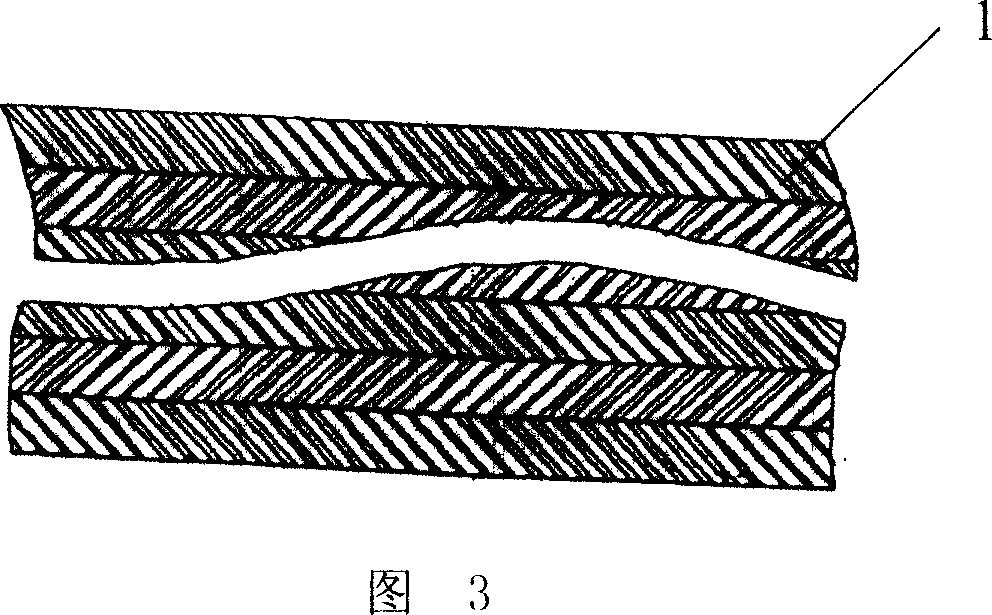

[0026] Now further illustrate specific embodiments of the present invention in conjunction with accompanying drawings. Fig. 4 shows the process of assembling the stator core by bonding method of the present invention. As shown in FIG. 4 , the new method for assembling the stator core of the motor involved in the present invention completes the assembly of the stator core through the assembly procedure of positioning lamination, bonding molding and assembling.

[0027] Position the lamination, stack the iron sheets together and align the inner diameter and outer circle of the iron sheets through mold positioning.

[0028] Adhesive molding, applying adhesive around the iron core formed by positioning laminations of iron chips, so that the iron core is bonded and formed. The binder used is insulating varnish for motor impregnation.

[0029] Assemble into one, press the bonded and formed iron core from both ends of the iron core at a high temperature where the insulating paint i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com