Method for positioning and clamping welding receiver lathing installation edges and device

A technology of welding casing and turning processing, which is applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., to solve the assembly error and the low efficiency of the clamping alignment process, meet the machining requirements, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

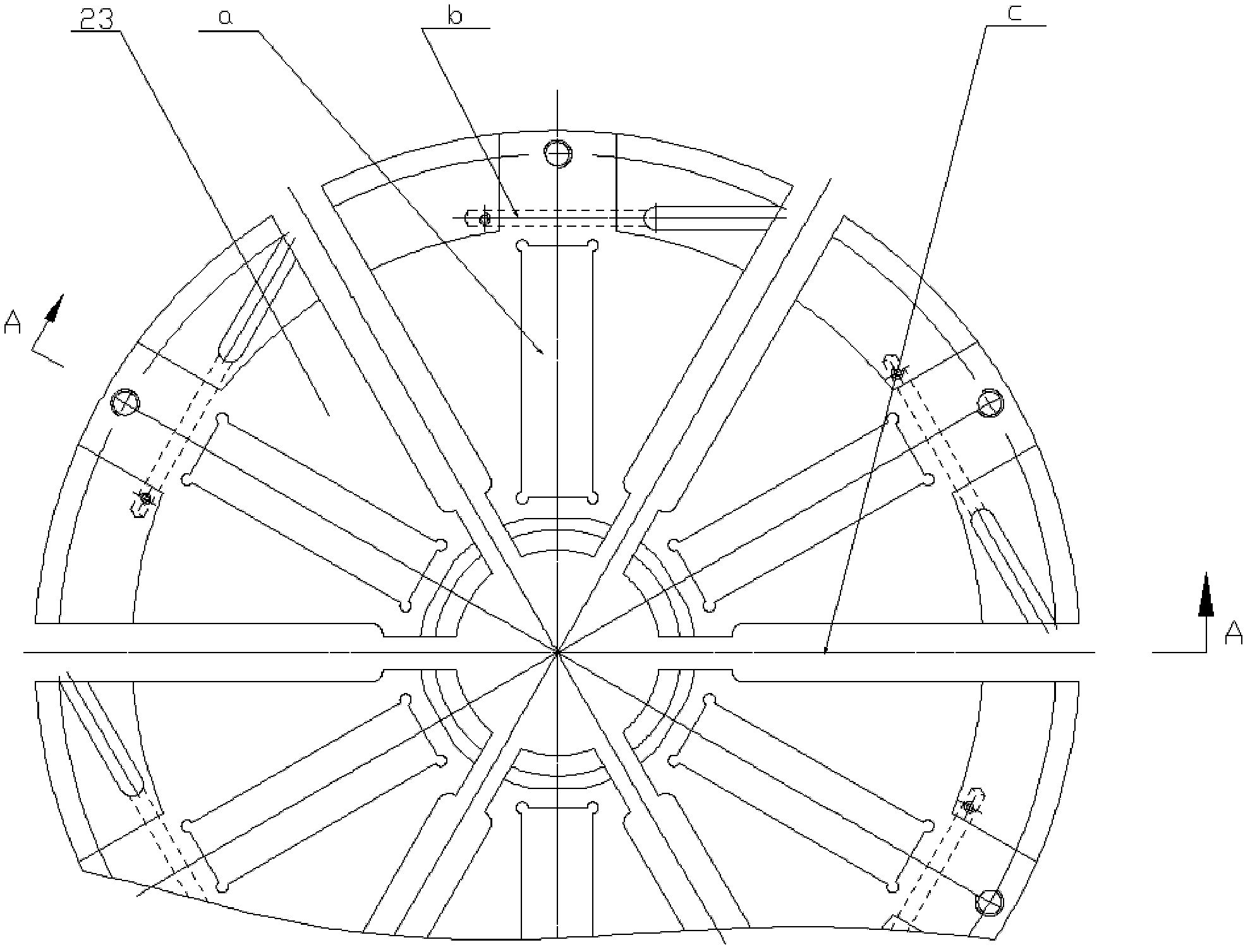

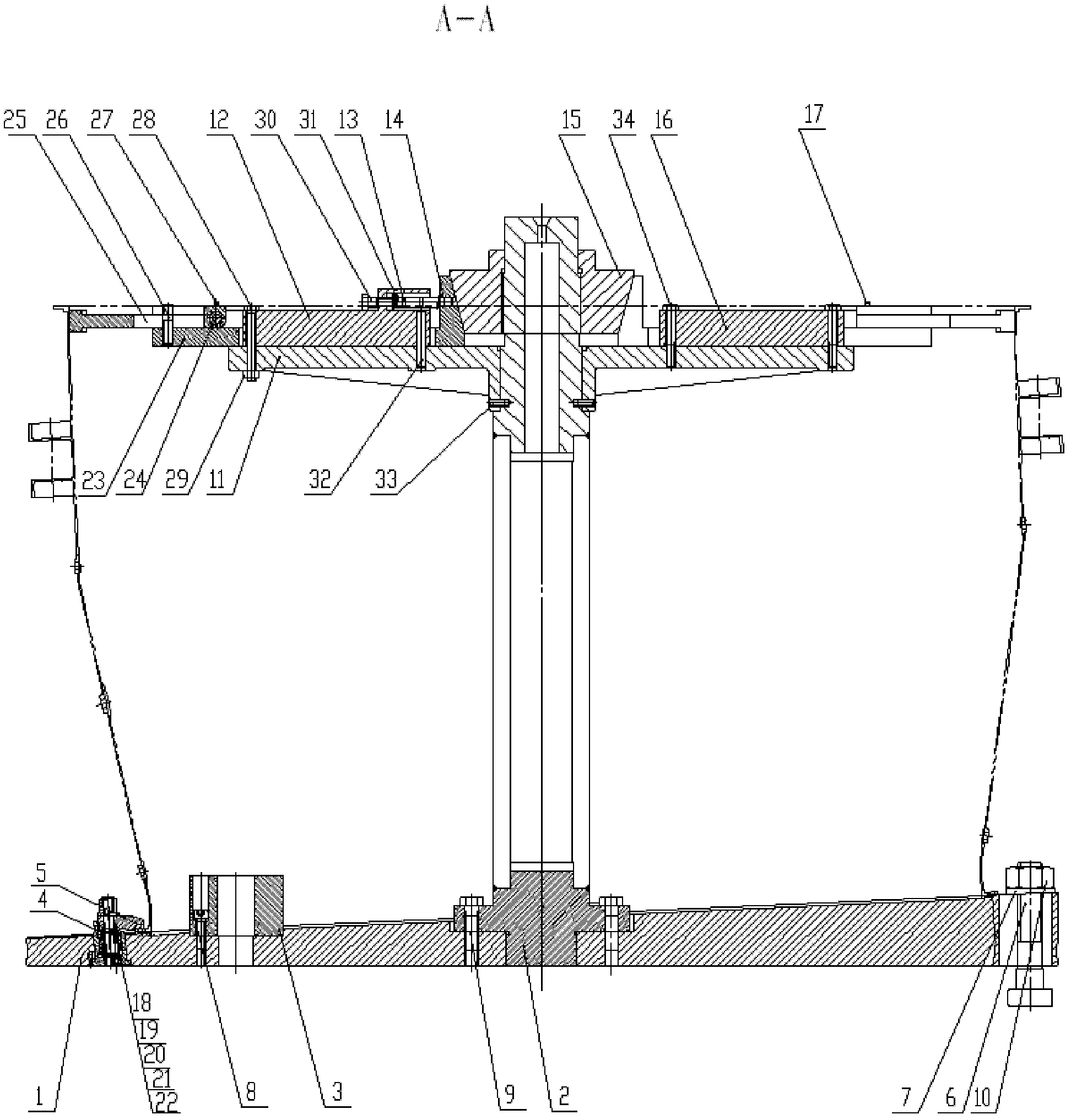

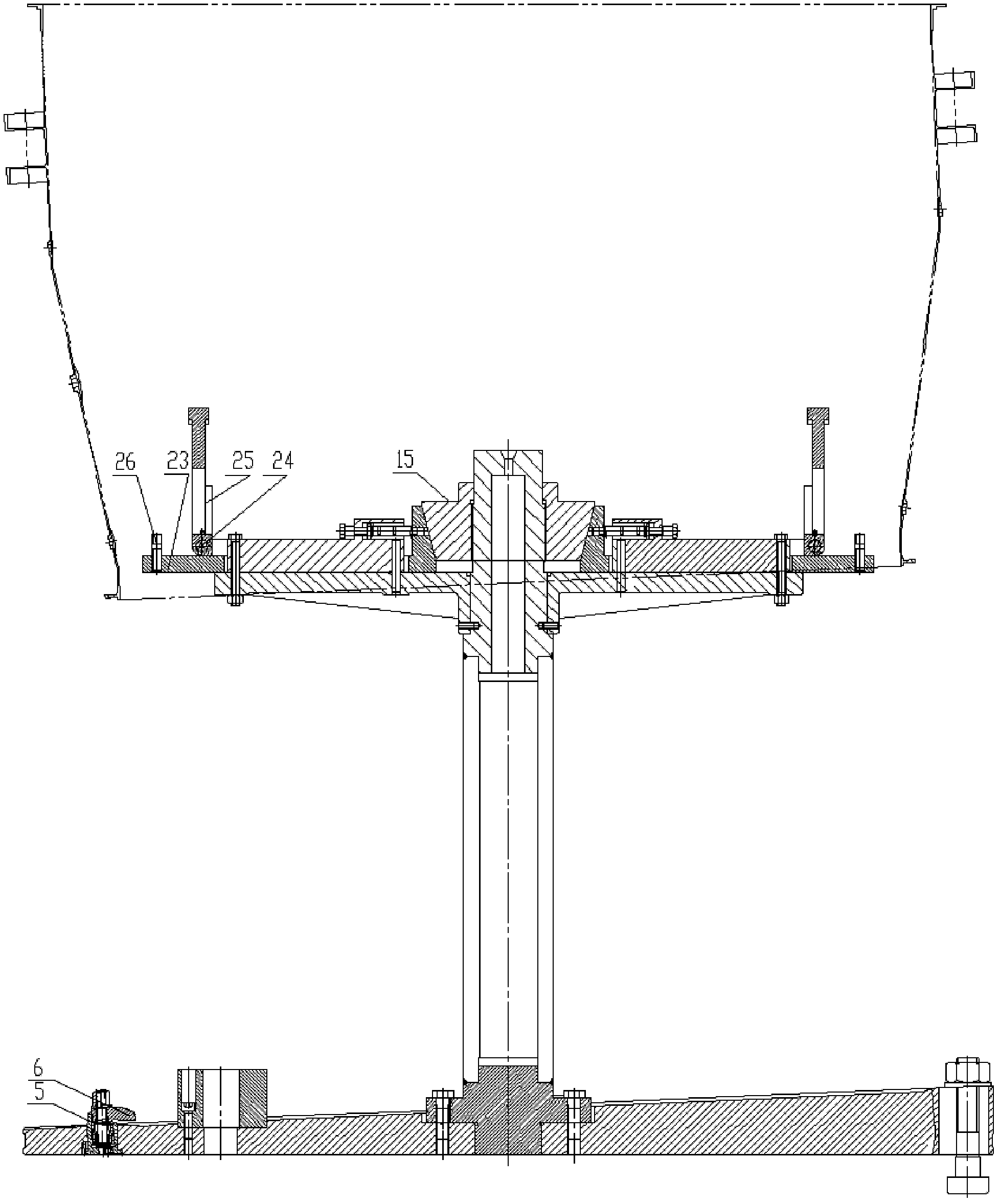

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The device provided by the present invention for clamping while machining and installing welding casings is composed of a fixed clamping mechanism and an expansion and positioning mechanism. The fixed clamping mechanism includes a chassis 1, a mandrel 2, a counterweight 3 and a pressure hook 5 , the chassis 1 with a positioning notch is fixed on the fixture installation base by the compression bolt 6, the mandrel 2 is coaxial with the chassis 1 and the lower end is fixedly connected to the chassis 1 by the bolt I9, and the counterweight 3 is fixed by the stop screw 8 Fixed on the side of the small end of the chassis 1, the pressure hook 5 is installed on the end of the chassis 1 through the assembly formed by the stud 19, the nut II18 and the nut III21, and the stud 19 is provided with a spring I20 and a sleeve 4 for fixing and pressing Parts; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com