Automatic aligning assembling system of parts

An automatic alignment and assembly system technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to complete automatic assembly, inability to automatically detect and adjust other workpieces, etc., to improve assembly accuracy and assembly efficiency, consistent Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

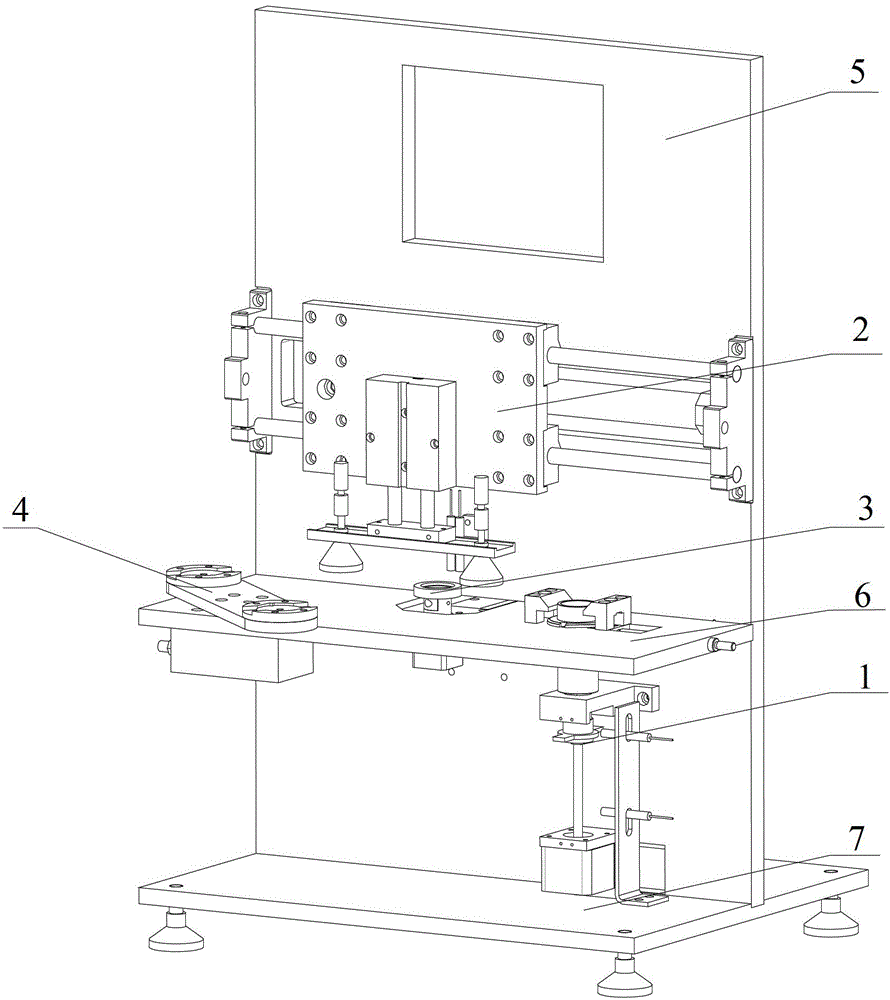

[0033] Such as figure 1 As shown, it is an automatic alignment assembly system for parts of the present invention, including: a vertically arranged bracket; a feeding device 1 for feeding parts at a designated position; a material shifting device 2 for transferring parts; orientation detection and adjustment The device 3 is used to detect and adjust the orientation of the parts; the assembly device 4 is used to accept and assemble the parts that have been aligned by the material transfer device 3; the feeding device 1, the orientation detection and adjustment device 3 and the assembly device 4 are placed on the platen 6 and set in sequence. The vertically arranged support includes a base plate 7, a vertical plate 5 and a platen 6, four supporting feet are installed under the base plate 7, the vertical plate 5 is vertically fixed on the base plate 7, the vertical plate 5 is the main support frame, and the platen 6 is horizontally fixed on the middle part of vertical plate 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com