Automatic assembling system and method for vehicle windshield glass

A windshield, automatic assembly technology, used in motor vehicles, transportation and packaging, manipulators, etc., can solve the problems of difficulty in contour detection and spatial positioning, dependence on assembly accuracy, and high labor intensity of workers, reducing the need for photography and positioning. Time, high degree of automation, the effect of saving time for taking pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

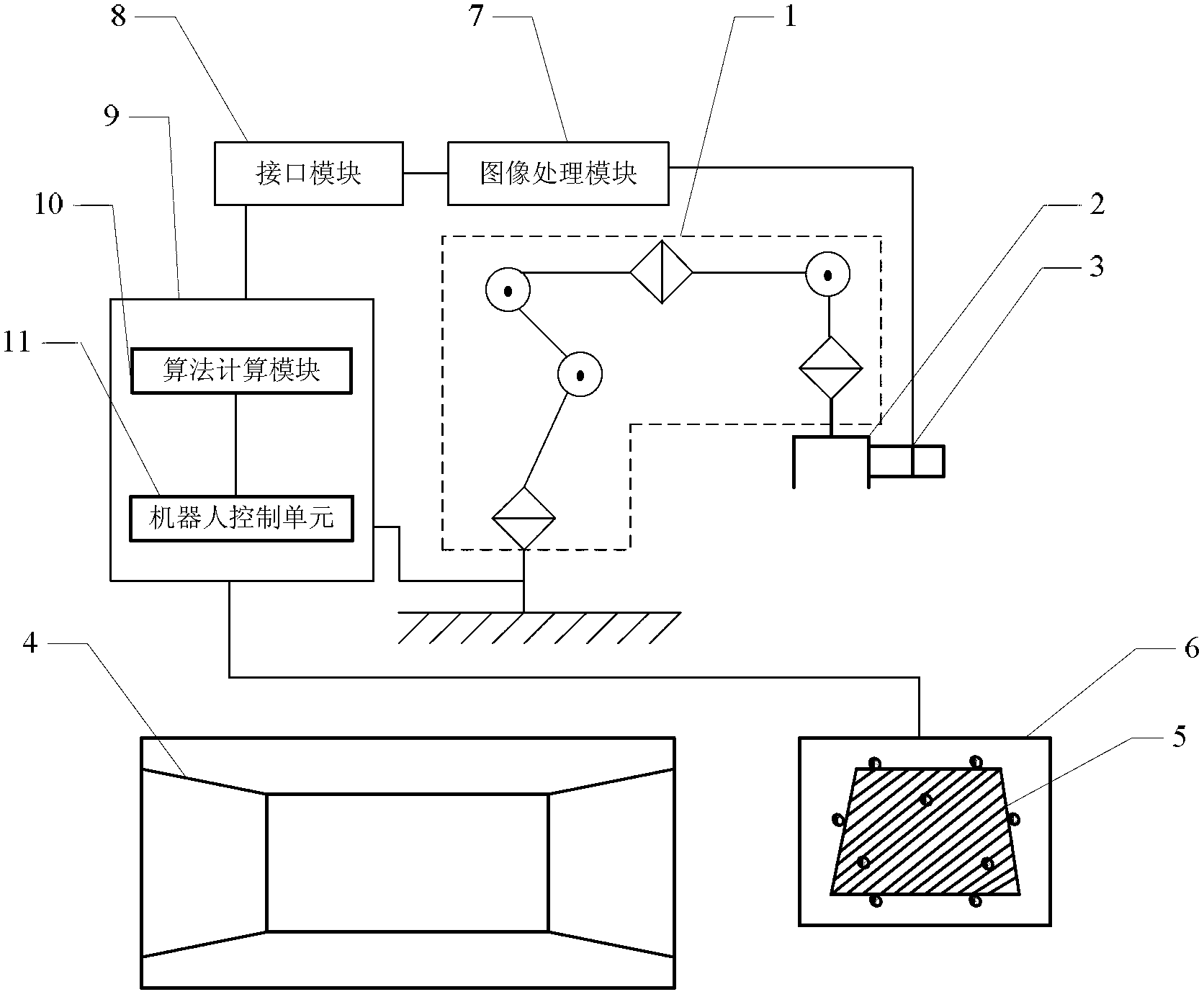

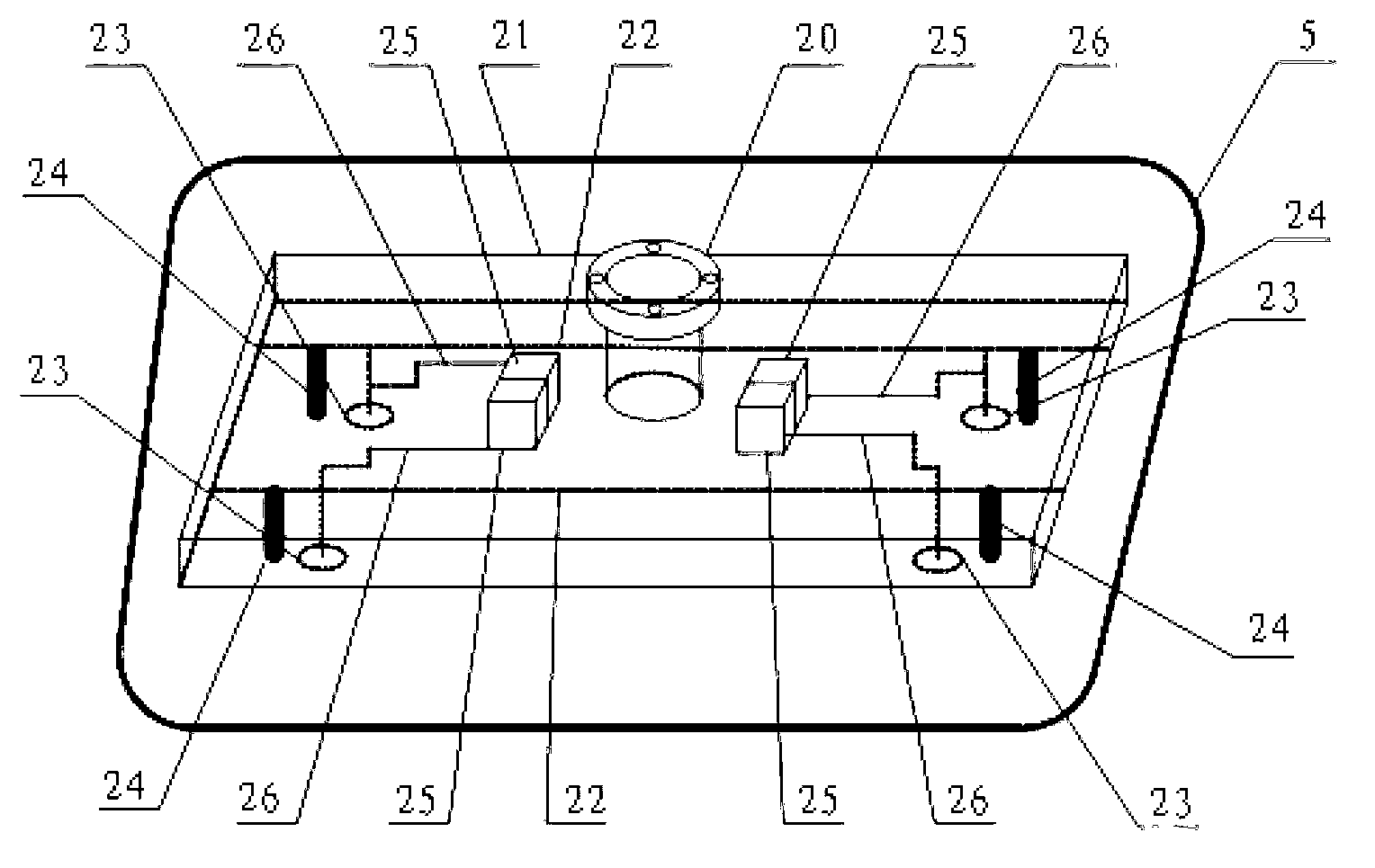

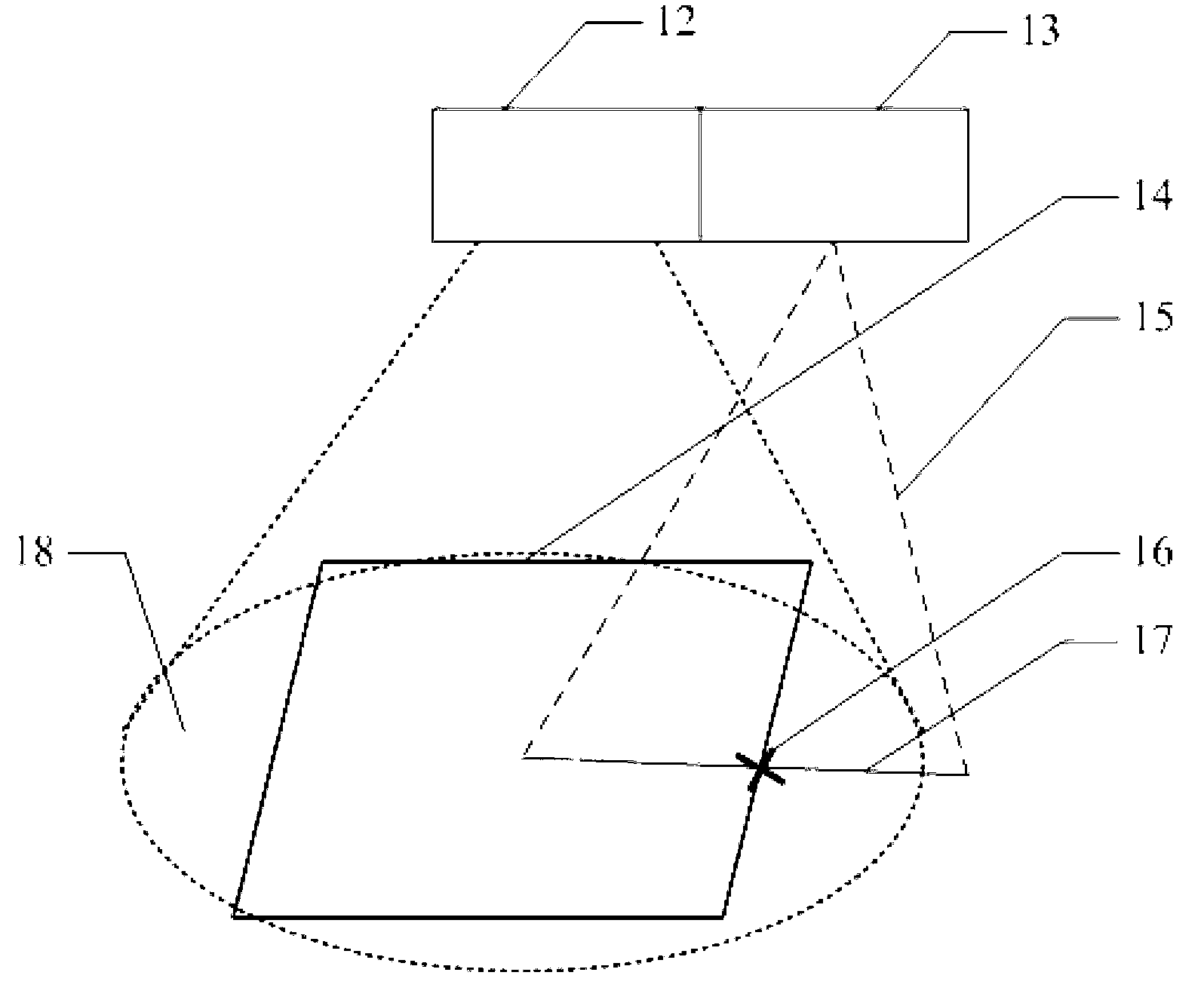

[0071] see Figure 1 to Figure 4 , the automatic assembly system of the automobile windshield of the present invention comprises a robot control cabinet 9, a robot module, a robot hand grip module 2, a visual inspection module, a glass centering module 6, a detected window frame 14 and a windshield glass 5.

[0072] The robot module includes a robot body 1, a robot control unit 11 that is connected to the robot body 1 and installed in a robot control cabinet. The robot body 1 is a standard six-degree-of-freedom joint robot or a robot with less degrees of freedom that can meet motion requirements or other similar equipment. The robot control unit 11 is the necessary software and hardware equipment for controlling the robot body 1, the first choice is the standard software or hardware supporting the robot body 1, but it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com