Precise positioning platform with six freedom of motion

A technology of precise positioning and degrees of freedom, applied in the parts, instruments, casings and other directions of instruments, can solve the problems of difficult to guarantee assembly accuracy, limited adjustment stroke, complex structure, etc., to improve assembly accuracy, reduce manufacturing difficulty, structure and other problems. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

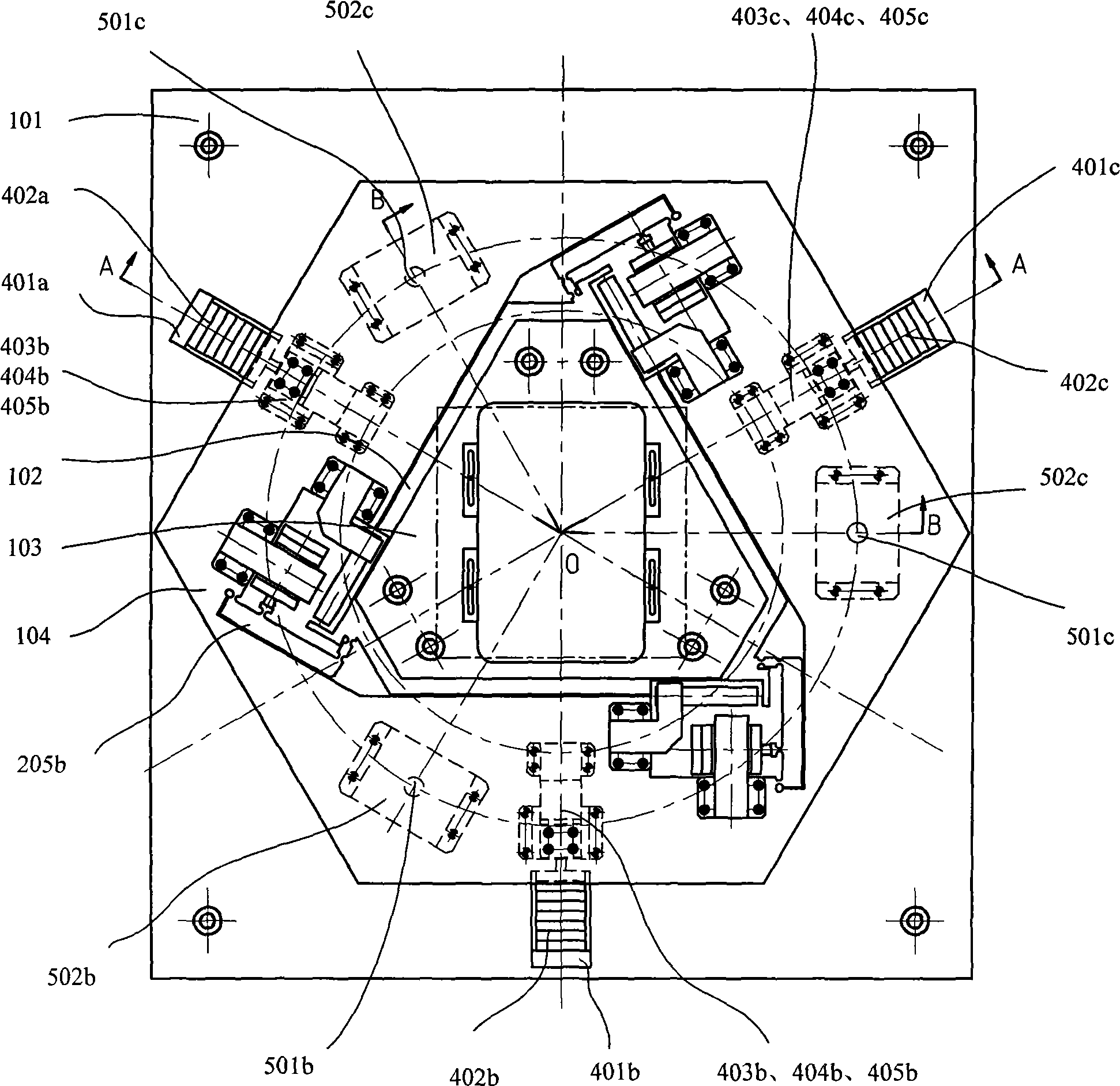

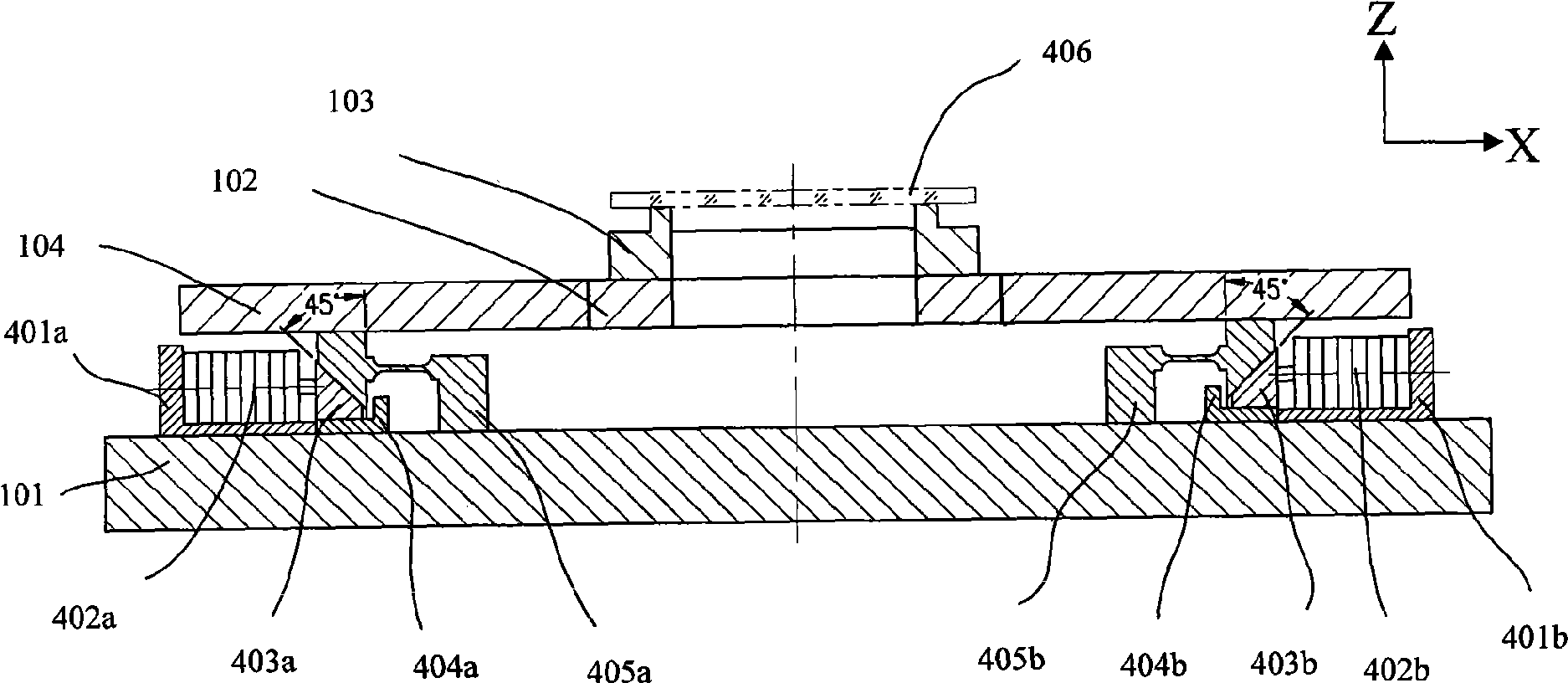

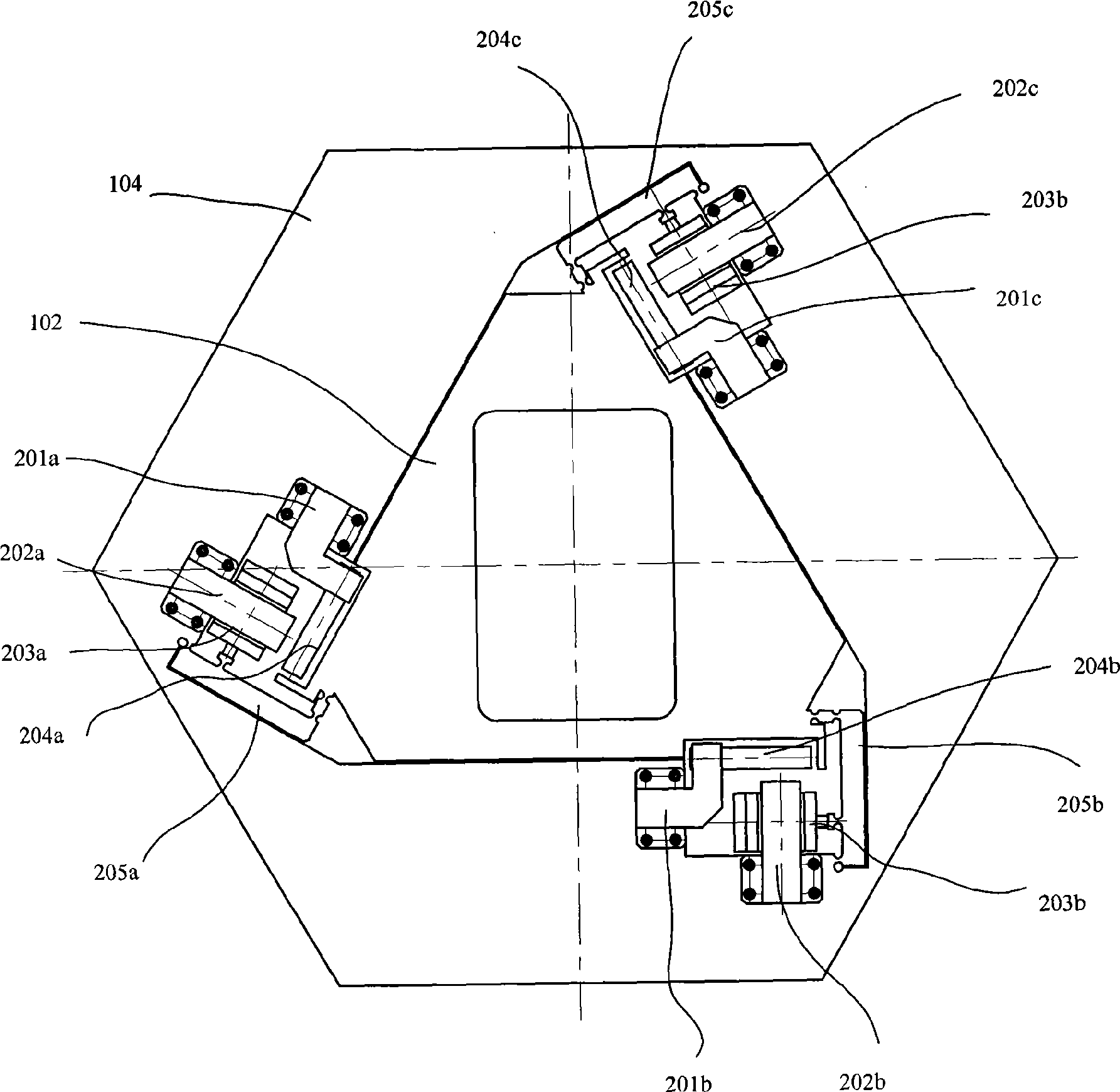

[0028] figure 1 Shown is the front view of the six-degree-of-freedom precision positioning platform of the preferred embodiment of the present invention; figure 2 shown as figure 1 The rotated sectional view along A-A in the center. Please refer to figure 1 and figure 2 .

[0029] The six-degree-of-freedom precision positioning platform disclosed in this embodiment is used to carry the reticle 406 printed with patterns for exposure, so as to position the pattern to be exposed to a designated position.

[0030] The overall structure of the six-degree-of-freedom precision positioning platform is divided into a suction plate 103 , a horizontal adjustment platform, a vertical adjustment platform and a base 101 from top to bottom.

[0031] The suction table 103 is used to vacuum absorb the retic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com