Automatic assembling mechanism for long tail clamp

An automatic assembly and assembly mechanism technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., to achieve the effect of reliable action, high assembly precision, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

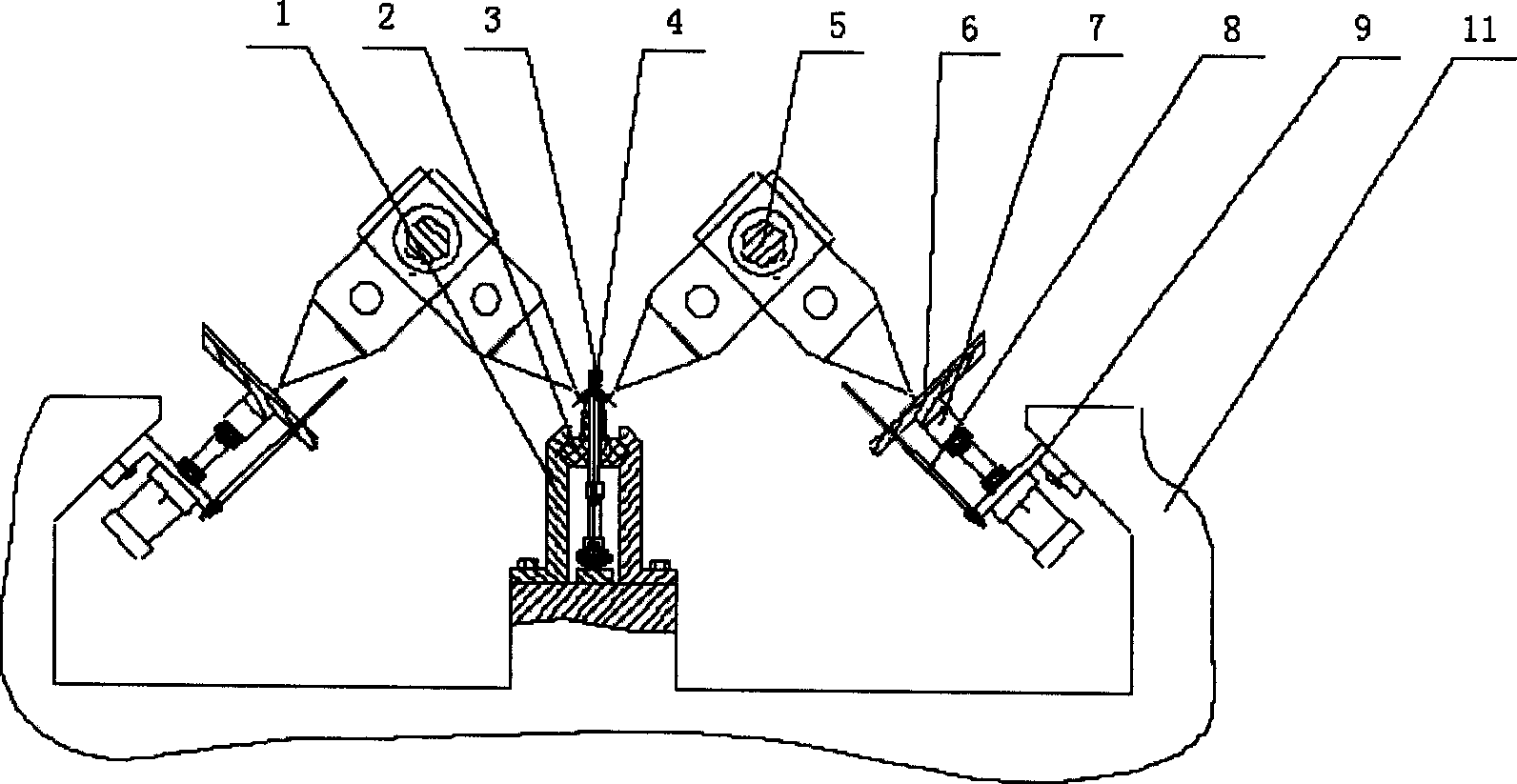

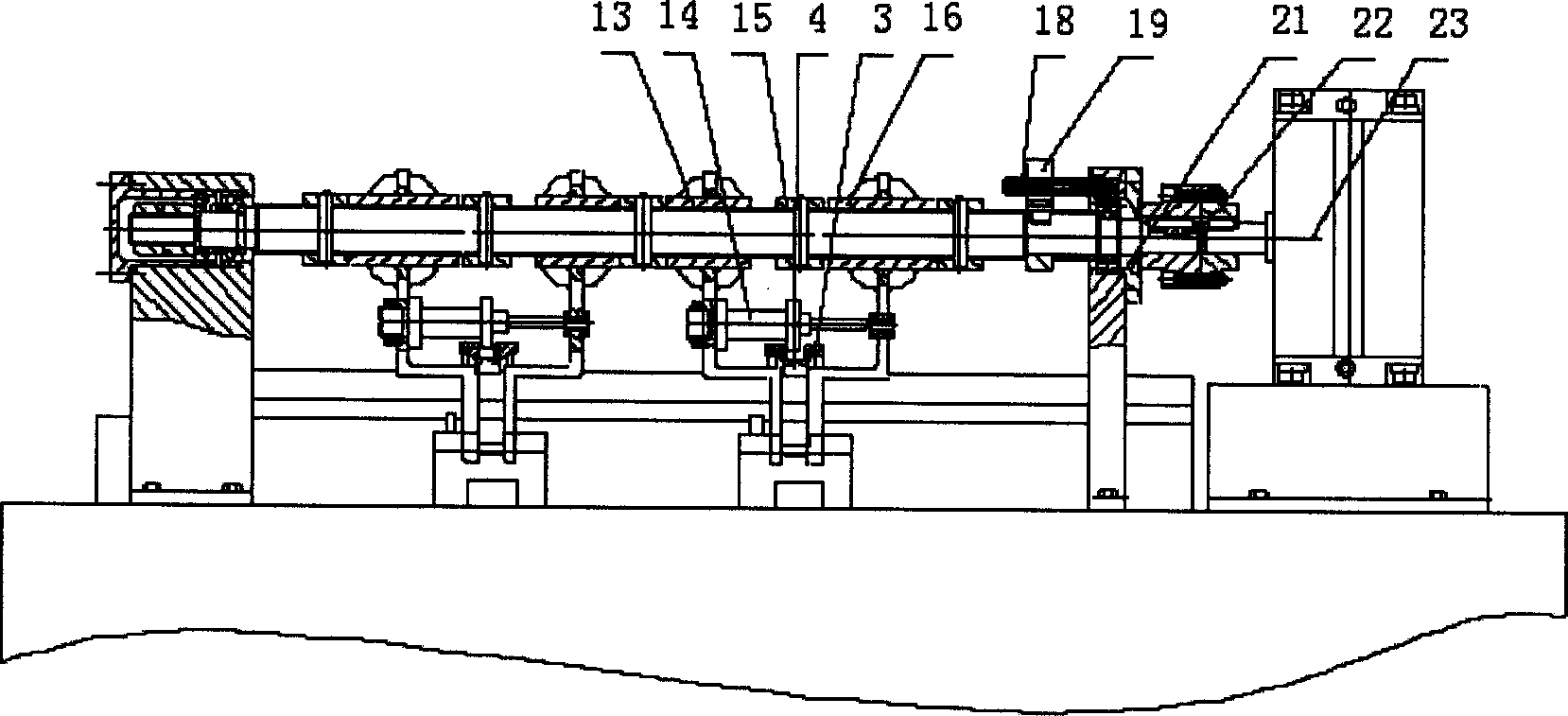

[0021] Embodiment 1: Referring to the accompanying drawings, an automatic assembly mechanism for long tail clips includes a workbench 11 on which there is a clip body positioning and conveying mechanism, a handle positioning and conveying mechanism, a handle assembly mechanism, and coordination and control of the above three mechanisms Action electric control device; the handle assembly mechanism includes: the spline shaft 5 connected with the swing cylinder 23, the left mechanical claw 13 and the right mechanical claw 16 are slidable and can rotate with the spline shaft and are connected to the spline shaft 5, the end cover and piston rod of the clamping cylinder are respectively connected to the left mechanical claw and the right mechanical claw; Positioning and conveying mechanism, handle positioning and matching position of conveying mechanism. The clamp body positioning and conveying mechanism includes: a fixed guide rail 1, a movable guide rail 2 that can slide in the fi...

Embodiment 2

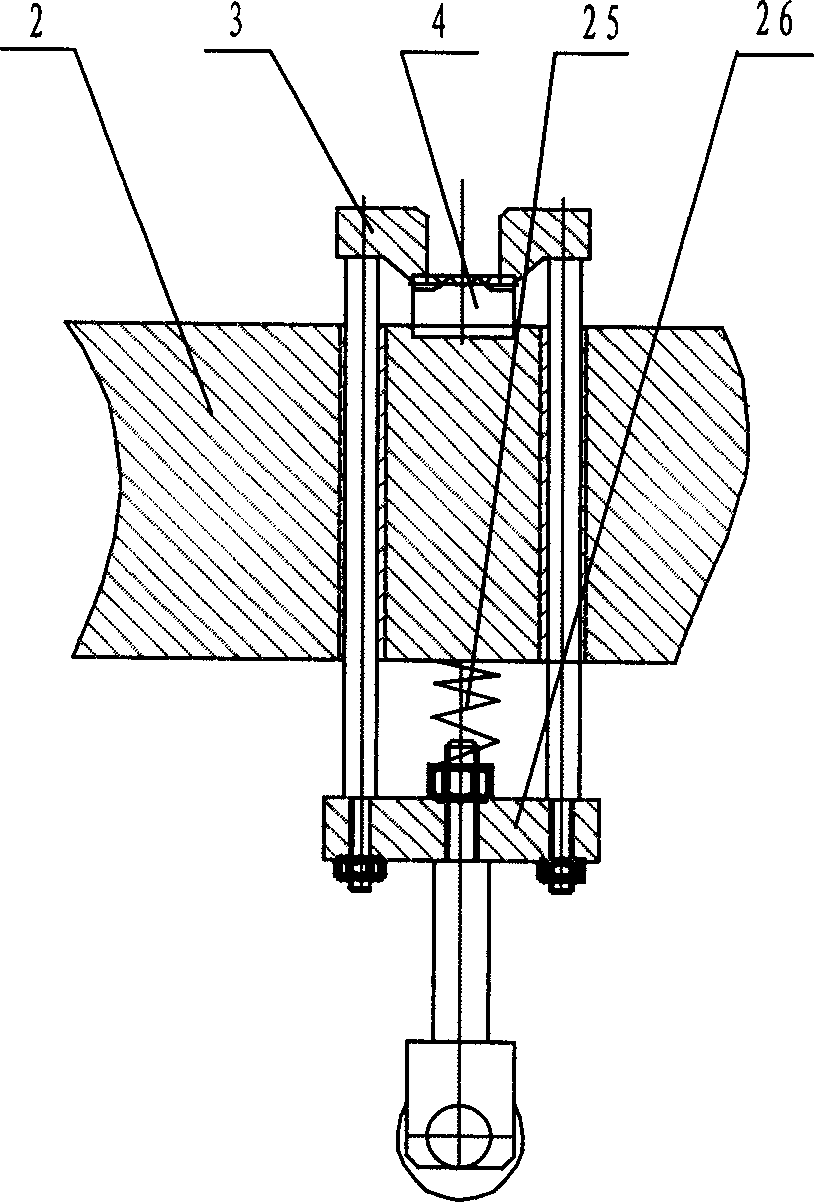

[0022] Embodiment 2: The clamping device of the clamp includes a guide rod that runs through the through hole of the movable guide rail, the upper end of the guide rod is located above the movable guide rail and a pressing plate 3 is provided, and the lower end of the guide rod is provided with a fixed plate 26. A spring 25 is arranged between the fixed plate and the movable guide rail. The movable guide rail is provided with a clamp body positioning groove. Others are the same as embodiment one.

Embodiment 3

[0023] Embodiment Three: The cylinder block 9 is provided with a guide rod 8 . The lifting trough 7 is provided with a conveying trough for conveying the handle, a handle positioning surface and a groove for the end of the mechanical claw to pass through. Described guide bar 8 is connected with lifting chute. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com