Composite material with high energy storage density and charge-discharge performance, and preparation method of composite material

A technology with charge-discharge performance and high energy storage density, which is applied to components, circuits, capacitors, etc. of fixed capacitors. It can solve the problems of low energy storage density and achieve the effect of good temperature stability and superior charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

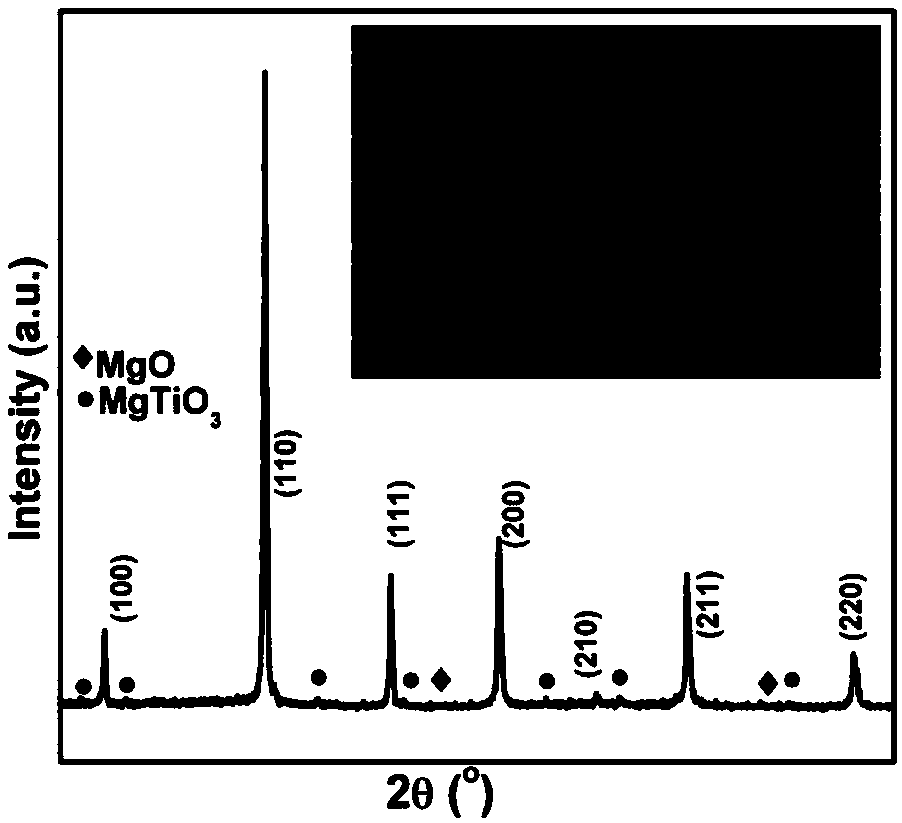

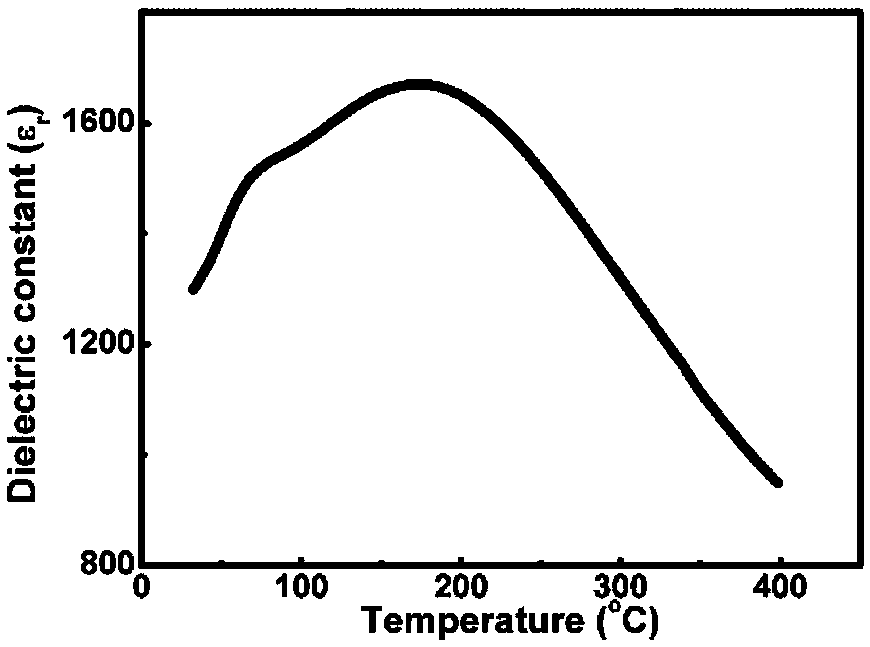

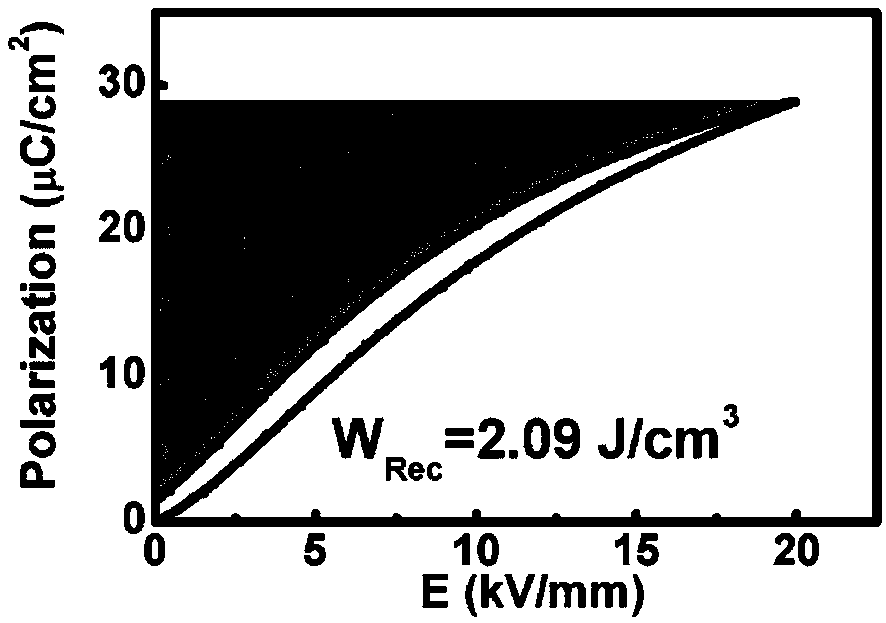

[0030] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , Na 2 CO 3 , SrCO 3 ,TiO 2 and MgO as raw materials for 0-3 type composites. According to chemical formula (Bi 0.32 Sr 0.42 Na 0.2 □ 0.06 )TiO 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 850°C at 5°C / min, keep it warm for 2 hours, cool it down to room temperature, and take it out with a grinder. Grinding in a bowl, pouring it into a corundum crucible again for compaction and calcining, the heating rate and holding time are the same as the first time.

[0031] (2) Adding the MgO raw material with a mass fraction of 3wt% to the powder obtained in step (1), and performing secondary ball milling, dischargin...

Embodiment 2

[0038] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , Na 2 CO 3 , SrCO 3 ,TiO 2 and MgO as raw materials for 0-3 type composites. According to chemical formula (Bi 0.32 Sr 0.42 Na 0.2 □ 0.06 )TiO 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 850°C at 5°C / min, keep it warm for 2 hours, cool it down to room temperature, and take it out with a grinder. Grinding in a bowl, pouring it into a corundum crucible again for compaction and calcining, the heating rate and holding time are the same as the first time.

[0039] (2) Adding the MgO raw material with a mass fraction of 3wt% to the powder obtained in step (1), and performing secondary ball milling, dischargin...

Embodiment 3

[0045] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , Na 2 CO 3 , SrCO 3 ,TiO 2 and MgO as raw materials for 0-3 type composites. According to chemical formula (Bi 0.32 Sr 0.42 Na 0.2 □ 0.06 )TiO 3 Weigh the material, add absolute ethanol and zirconia balls into the nylon tank for ball milling, discharge, and dry. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, cover the crucible after compaction, put it into a muffle furnace for calcination, raise it to 850°C at 5°C / min, keep it warm for 2 hours, cool it down to room temperature, and take it out with a grinder. Grinding in a bowl, pouring it into a corundum crucible again for compaction and calcining, the heating rate and holding time are the same as the first time.

[0046] (2) Adding the MgO raw material with a mass fraction of 3wt% to the powder obtained in step (1), and performing secondary ball milling, dischargin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com