Coupling type heating method for preparing pyrogallic acid

A pyrogallic acid and coupled technology, which is applied in the field of coupled heating to produce pyrogallic acid, can solve the problems of unreasonable energy use, poor cooling effect of crystallizer, unstable product quality, etc., and achieve stable and reliable quality, product raw materials The effect of low consumption and short discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

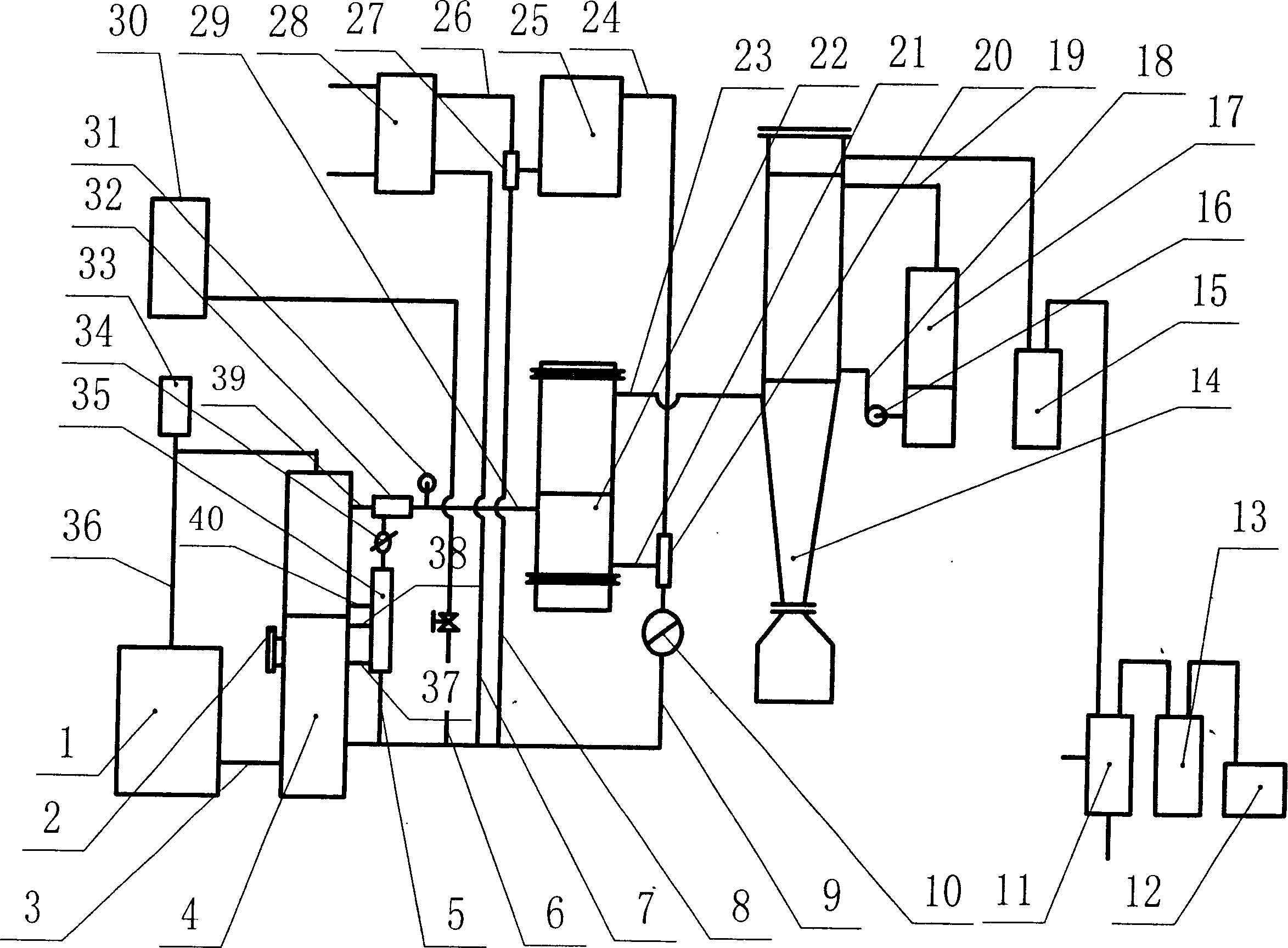

[0019] As the method for producing pyrogallic acid shown in the accompanying drawing, 100 kg of raw material gallic acid is added to the drier 25, and the gallic acid is dried by secondary steam with a temperature of 240° C., dried for 4 hours and discharged, and the residual steam of the dried raw material gallic acid, After passing through the flow divider 27 and the condensing hot water bucket 28 , the condensed water returns to the coupler 4 as supplementary water; the supplementary water required by the coupler is mainly supplied by the supplementary water device 30 . Open the top cover of sublimator 22 then, add the gallic acid that has dried from here. At the same time, add high boiling point medium superheater cylinder oil into coupler 4 and heater 1, observe the oil level from the expansion oil seal to make it have the required liquid level; add water medium into the shell of the evaporation section of coupler 4 , observe the water level gauge 2 located on the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com