Device and method for processing thermosetting plastics

A thermosetting and equipment technology, used in the field of processing thermosetting plastics, can solve problems such as equipment not working, and achieve the effect of high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

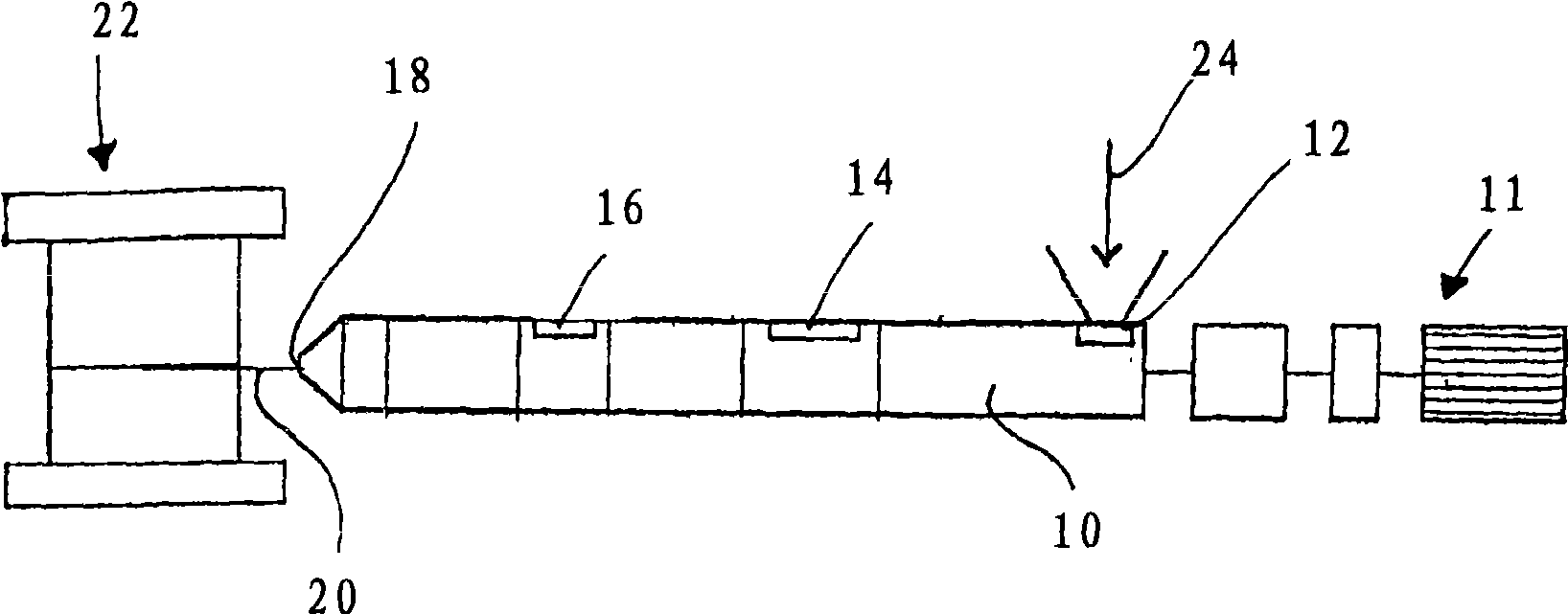

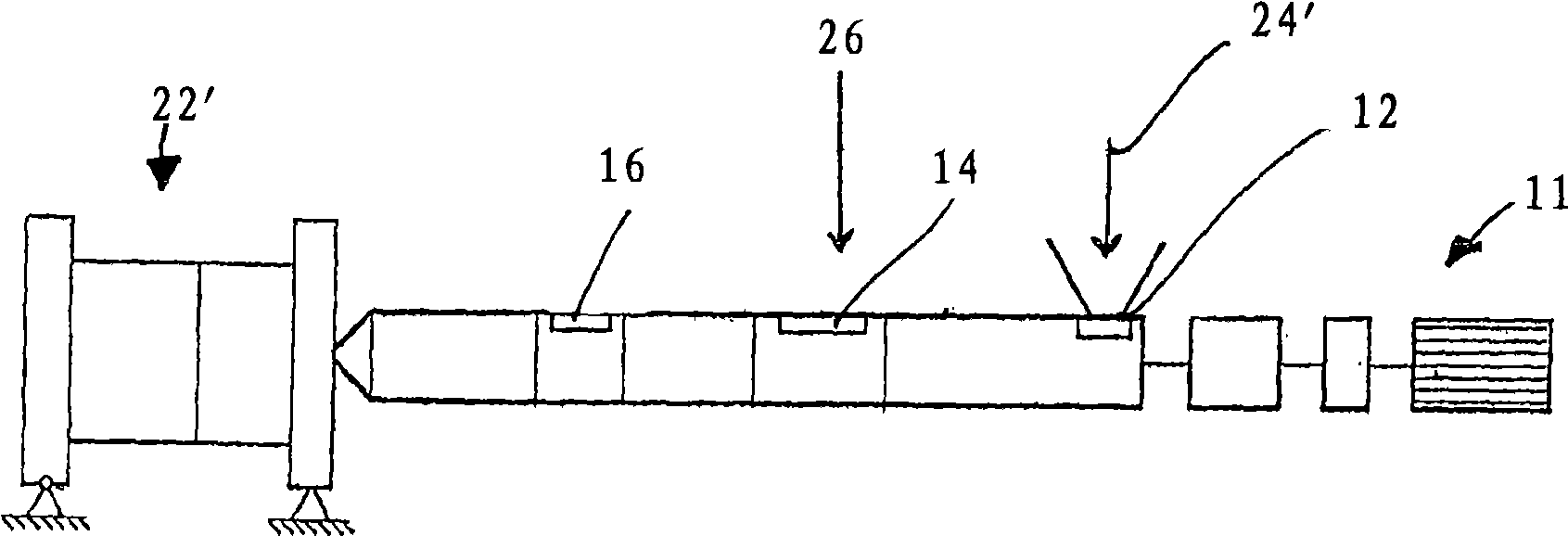

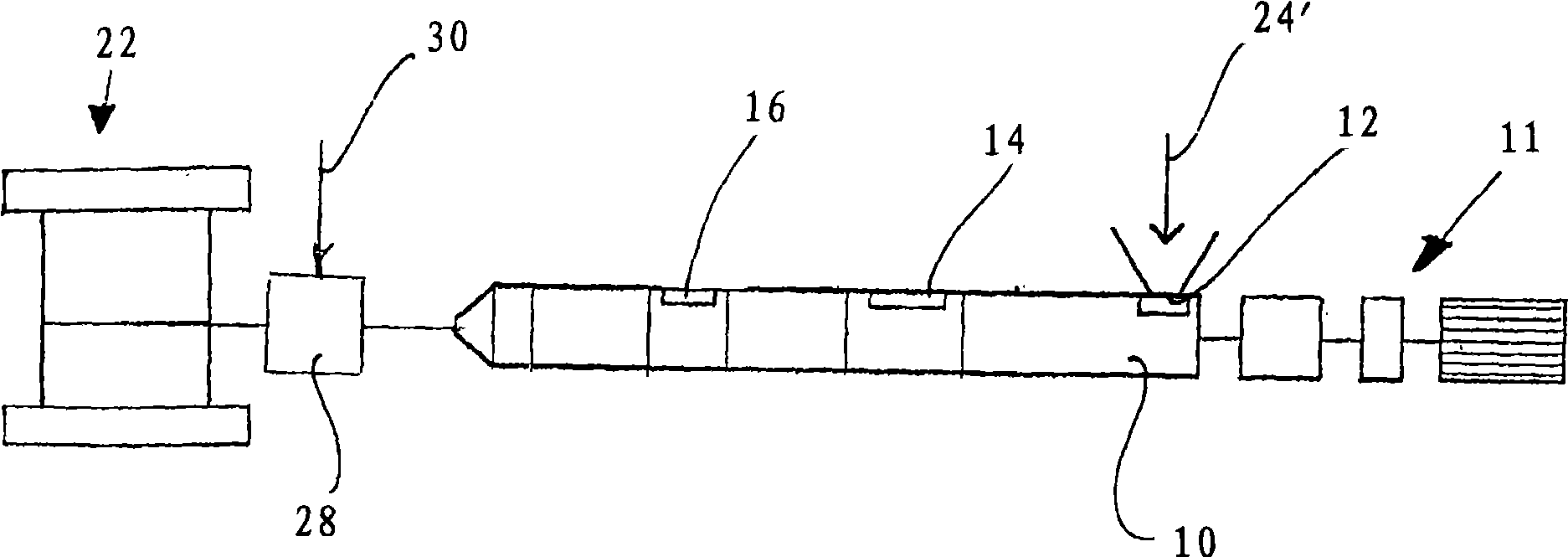

[0029] exist figure 1 A first embodiment of the invention is shown in a very simplified schematic form, which comprises an extrusion device 10 as the central element. The extrusion device (extruder for short) 10 is now designed as a co-rotating twin-screw extruder comprising two extrusion screws (not shown) and an extrusion cylinder surrounding the two extrusion screws. The extrusion device 10 comprises a plurality of filling openings 12 , 14 and 16 , through which material can be fed into different process areas, as will also be described below.

[0030] The two extrusion screws are driven in rotation by a drive 11 , wherein the drive comprises a rotary drive, for example in the form of an electric motor, and a transmission.

[0031]On the end of the downstream side of the extruder, the material processed in the extrusion device 10 is conveyed through an outlet 18 to an injection pipe 20, which connects the extruder 10 to an injection mold 22, which This is likewise shown o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com