Exhaust gas-purifying device

a technology of exhaust gas and purification device, which is applied in the direction of machine/engine, magnetic separation, separation process, etc., can solve the problems of clogging of particulate filter, excessive amount of particles, etc., and achieve the effect of reliable burning o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

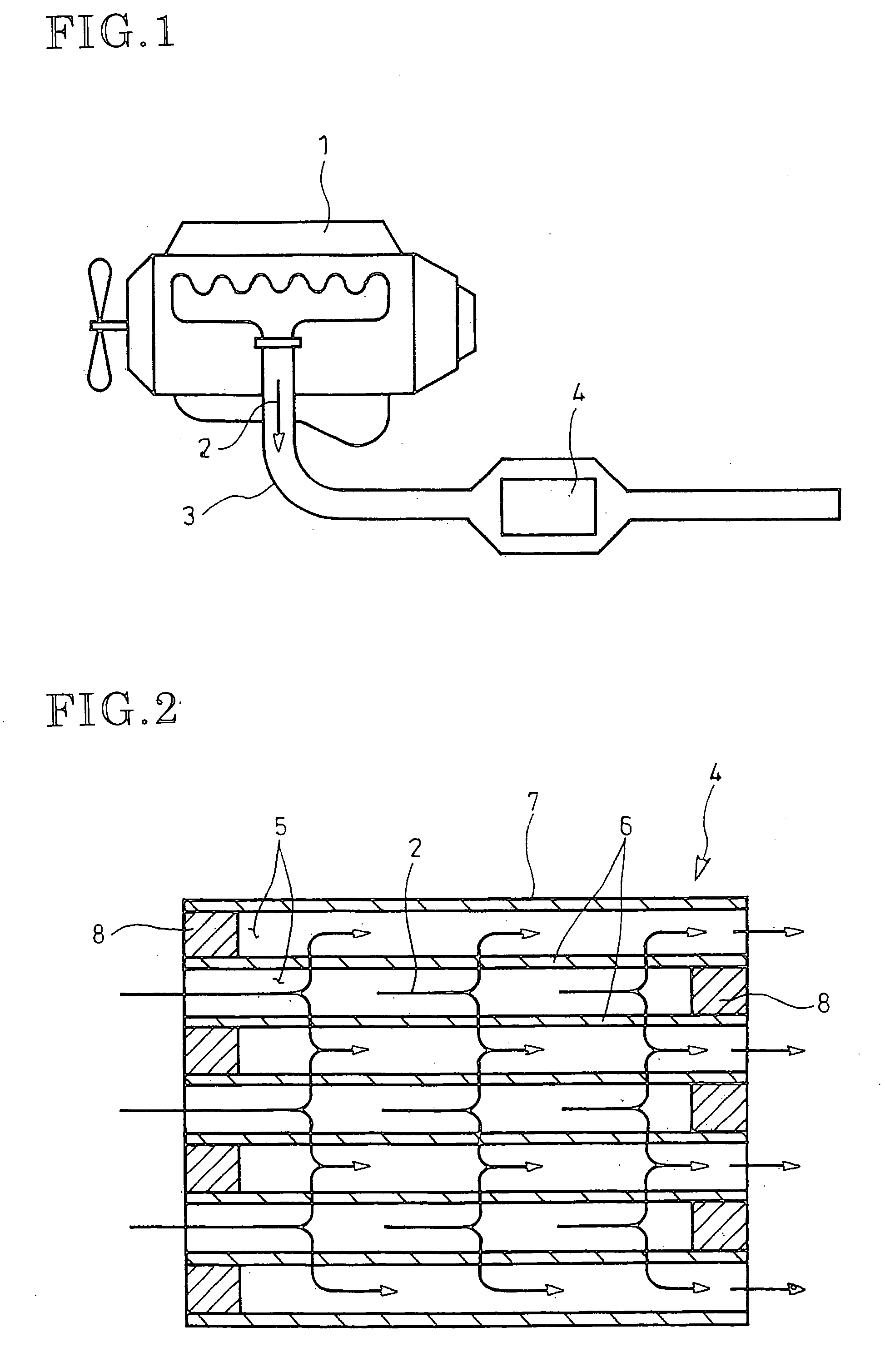

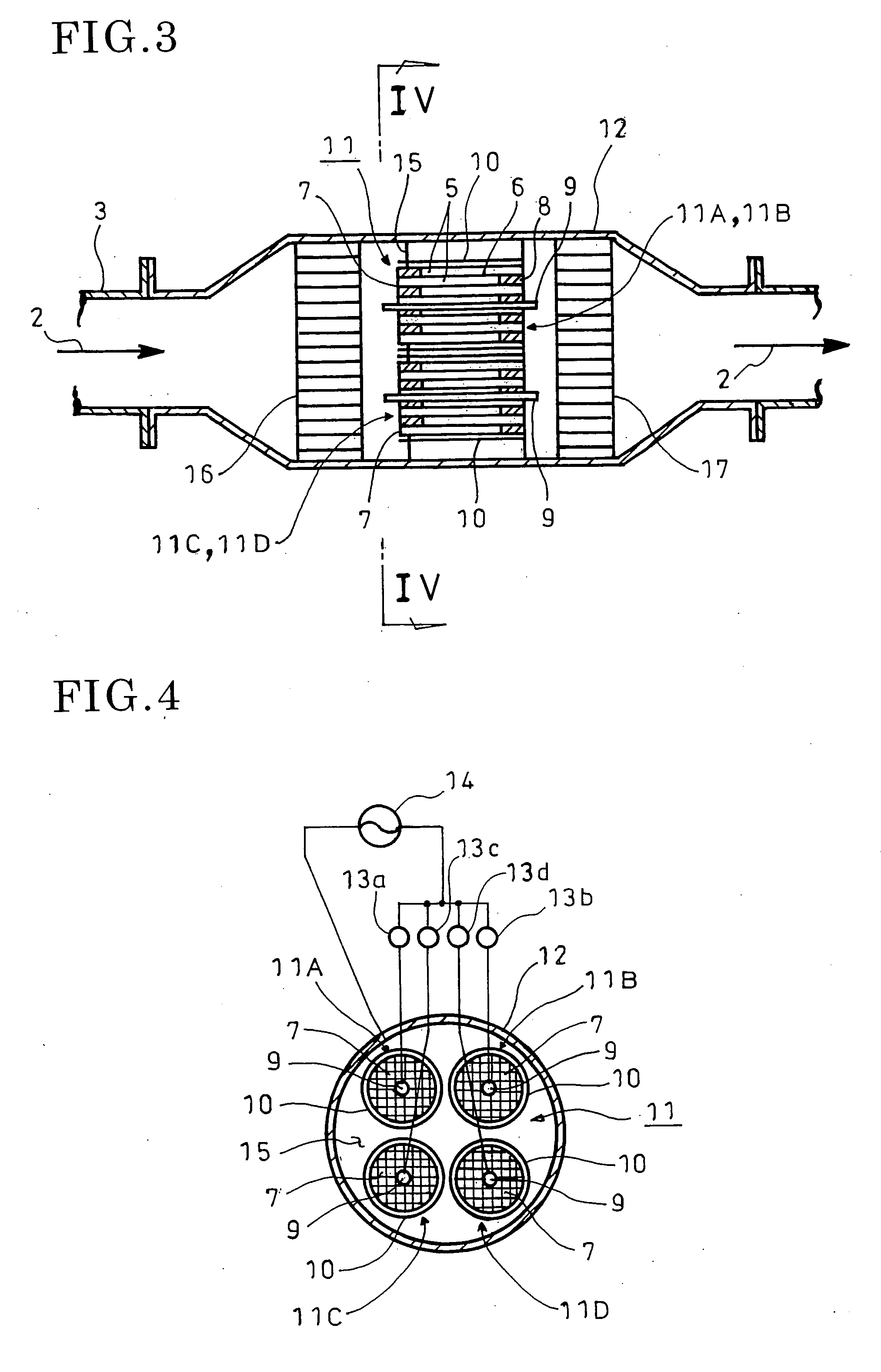

[0043] An embodiment of the invention will be described in conjunction with the drawings.

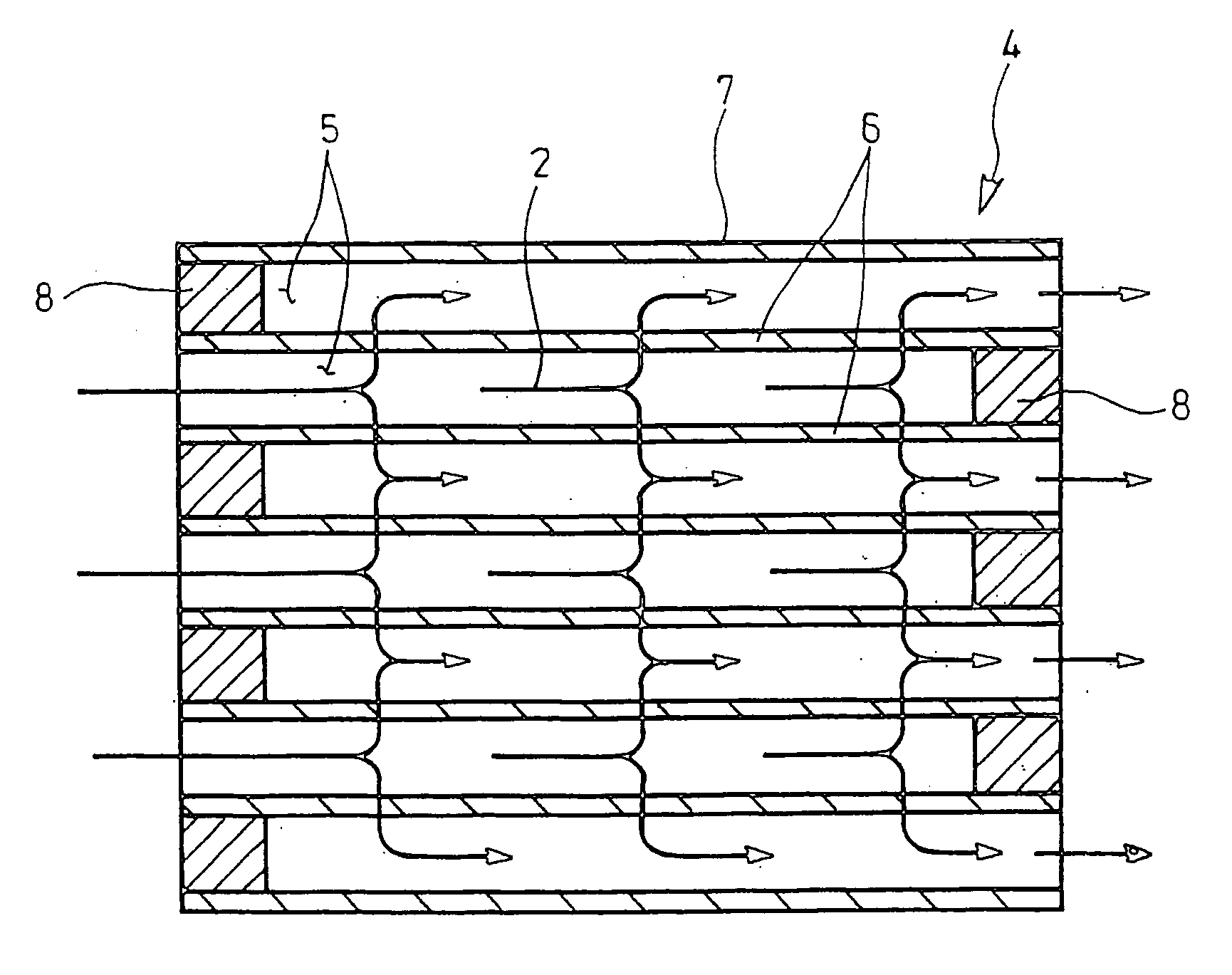

[0044]FIGS. 3 and 4 show an embodiment of the invention in which parts similar to those in FIGS. 1 and 2 are represented by the same reference numerals.

[0045] As shown in FIGS. 3 and 4, used in an exhaust emission control device of the invention is a plasma regenerative particulate filter 11 comprising a filter body 7 similar to that shown in FIG. 2 above and rod-like and cylindrical electrodes 9 and 10 so as to generate plasma in the filter body 7. Shown is an example of the plasma regenerative particulate filter 11 divided into a plurality of (four in the figure shown) smaller units 11A, 11B, 11C and 11D which are arranged in parallel with each other within the filter casing 12.

[0046] The filter body 7 in each of the smaller units 11A, 11B, 11C and 11D has the rod-like electrode 9 inserted into an axis of the filter body 7 and the cylindrical electrode 10 fitted over the outer periphery of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com