High-efficiency, low-energy-consumption and free-of-secondary-pollution method and device using low-temperature plasma to synergistically catalytically purify indoor volatile organic compounds

A low-temperature plasma and volatile organic compound technology, applied in the field of indoor air purification, can solve the problems of high energy consumption and large air resistance, and achieve the effects of low energy consumption, high conversion efficiency, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

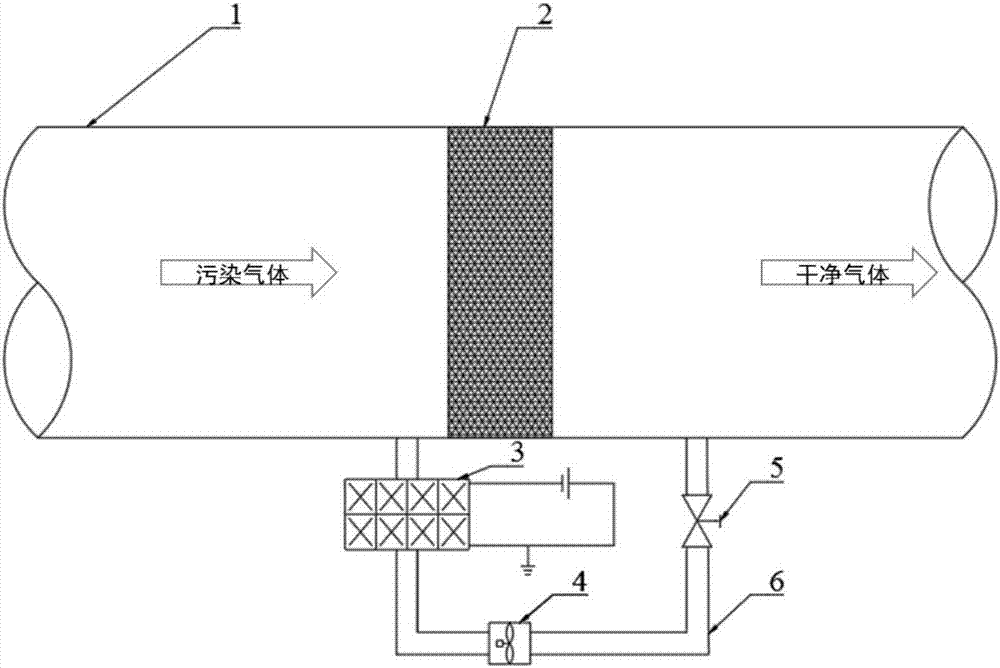

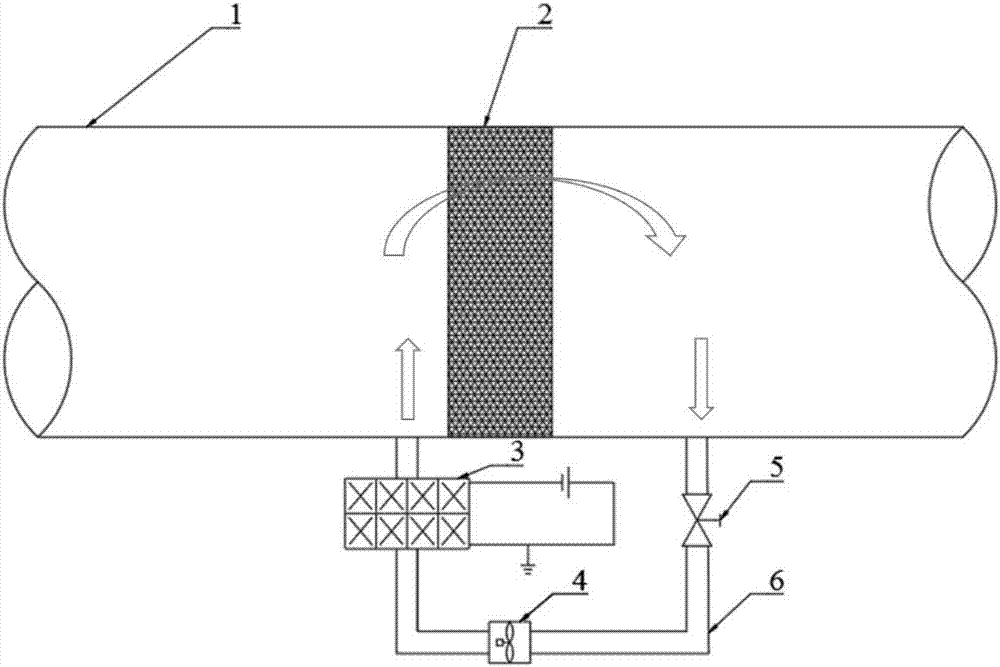

Embodiment 1

[0037] The air purifier in an office has a rectangular air duct with a size of 320mm×250mm, and the low-temperature plasma generator 3, fan 4 and stop valve 5 are bypassed, and a circular plexiglass tube or stainless steel tube with an inner diameter of 50mm is used. connect. The low-temperature plasma generator 3 is designed in a string-column shape, and 8 cylinders are connected in parallel. The string wire is the discharge electrode, the cylinder is the ground electrode, and 8kV negative polarity DC high voltage power is applied between them. The serial wire discharge electrode is a stainless steel rod with an inner diameter of 3mm and several discharge gears connected in series at equal intervals. Each gear is evenly distributed with 4 discharge tips, and the distance between the discharge gears is 10mm; the ground electrode is a cylindrical stainless steel tube with an inner diameter of 22mm. The thickness is 1mm, and the length of the steel pipe is 300mm. 1%Ag~5%Mn / γ-A...

b example 2

[0039] The size of the air cleaner in the office is a rectangular air duct of 250mm × 250mm, which is bypassed to connect the low-temperature plasma generator 3, fan 4 and shut-off valve 5, and is connected with a circular plexiglass tube or stainless steel tube with an inner diameter of 50mm. The low-temperature plasma generator 3 is designed as a pin-hole plate type, with a plurality of needle-like conductors attached to the metal plate as discharge electrodes, a stainless steel plate with holes as a ground electrode, and holes are drilled in the plexiglass tube to connect conductive terminals for Connect the positive and negative poles of the high-voltage power supply, and apply a 6kV positive polarity DC high-voltage power supply between them. The needle tip radius is 0.5mm, the needle needle spacing is 5mm, and the needle plate spacing is 5mm. Prepare the 3%Ce~5%Mn / ZSM-5 adsorption / catalysis dual-function purification material into a 230mm×200mm×50mm honeycomb rectangular...

Embodiment 3

[0041]The air purifier in a student’s classroom is connected to the low-temperature plasma generator 3, fan 4 and stop valve 5 by way of a rectangular air duct with a size of 320mm×200mm, and a circular plexiglass tube or stainless steel tube with an inner diameter of 50mm is used. connect. The low-temperature plasma generator 3 is designed as a wire-plate type, with a plexiglass rectangular tube as the reactor shell, multiple nickel-chromium alloy wires with a diameter of 0.5mm as the discharge electrodes, and a stainless steel plate as the ground electrode. Drill holes to connect the conductive terminals to connect the positive and negative poles of the high-voltage power supply, and apply 8kV negative polarity DC high-voltage power supply between them. Prepare the 1%Ag~3%Mn / ZSM-5 adsorption / catalysis dual-function purification material into a 290mm×170mm×50mm honeycomb rectangular component 2 and install it in the air purifier, and the air volume during normal adsorption is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com