Method for welding combustor liner and tile pads of aeroengine

A technology of aero-engines and welding methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increased production cost and cycle, large amount of metal cutting, low material utilization rate, etc., to increase production cost and cycle problems, large amount of metal removal, and low material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

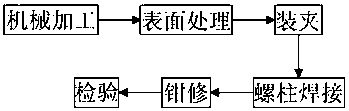

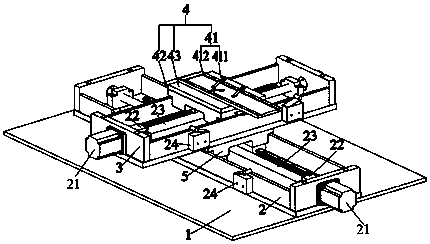

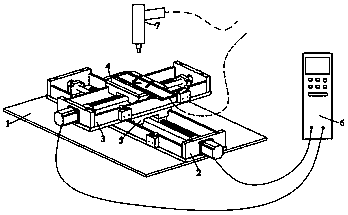

[0055] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 A kind of aeroengine flame tube tile welding method shown in this embodiment comprises fixture base 1, X slide rail 2, motor 21, shaft coupling 22, screw mandrel 23, limiter 24, Y slide rail 3, clamping device 4 , clamping part 41, piano key press 411, metal backing plate 412, slider 1 42, rubber pad 43, slider 2 5, controller 6, stud welding machine 7, floating tile 8, stud 9, arc The basic principle of stud welding is to ignite the arc between the stud to be welded and the workpiece. When the stud and the workpiece are heated to a suitable temperature, under the action of external force, the stud is sent into the welding pool on the workpiece to form a welded joint. The welding process is short time, high current and small penetration during stud welding, so it can be welded to very thin plates. For the plate thickness of short-cycle drawn arc stud welding, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com