Method and device for controlling dehydration of washing machine

A control method and washing machine technology, which are applied in the control device of washing machine, washing device, textiles and papermaking, etc., can solve the problems of long sampling time, inability to hit the barrel, large unbalanced error, etc., and achieve good balance and dehydration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

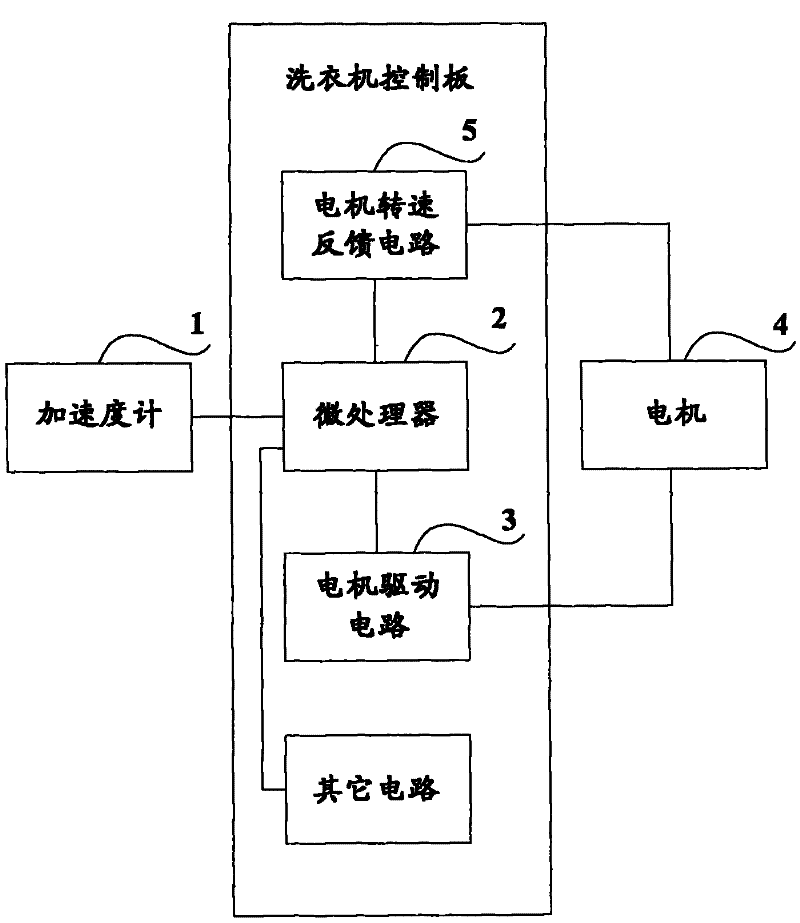

[0019] figure 1 It is a structural diagram of the washing machine dehydration control device of the present invention. The washing machine control board includes a microprocessor 2, a motor drive circuit 3, a motor speed feedback circuit 5 and other circuits. The specific connection relationship is: the microprocessor 2 is connected to the accelerometer 1, the motor drive circuit 3, and the motor speed feedback circuit 5 The motor 4 is connected to the motor drive circuit 3 and the motor speed feedback circuit 5 respectively.

[0020] The connection relationship and working principle of each circuit will be described in detail below with reference to the accompanying drawings.

[0021] The motor drive circuit 3 is used to drive the motor.

[0022] The motor 4 is used to drive the washing machine to rotate.

[0023] The accelerometer 1 is fixed on the outer tub of the washing machine, and is used to measure the vibration of the machine and feed back the collected acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com