Catalyst for low-temperature-curing addition-type silicone rubber and preparation method thereof

A technology of catalyst and silicone rubber, which is applied in the field of low-temperature-cured addition-type silicone rubber catalyst and its preparation, can solve problems such as easy leakage, and achieve the effects of avoiding reactions, simplifying storage and transportation methods, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

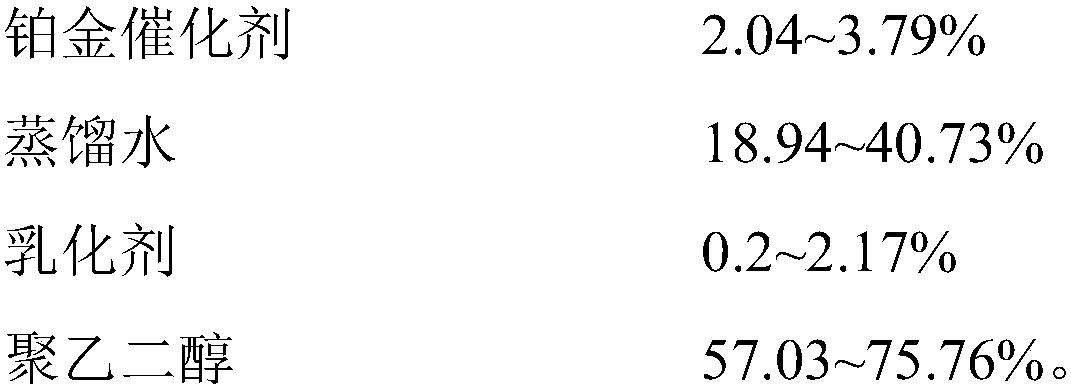

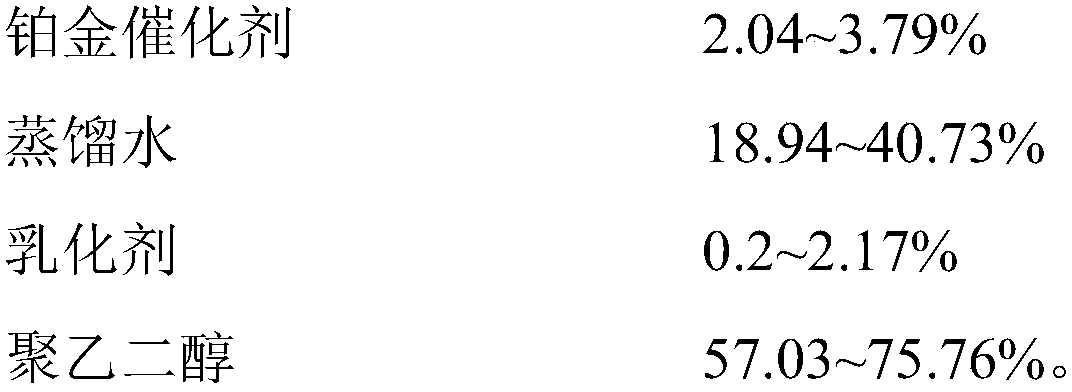

Method used

Image

Examples

Embodiment 1

[0027] Platinum catalyst emulsification: 10 grams of Custer platinum catalyst of 1000 ppm, 100 grams of distilled water and 6 grams of gum arabic are placed in a three-necked flask with a stirrer, and stirred for 1.5 hours at a speed of 1500 rpm to obtain oil- water emulsion;

[0028] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 65°C, keep the stirring speed at 1500 rpm, gradually add 160 grams of polyethylene glycol with an average molecular weight of 18000 to the oil-water emulsion alcohol;

[0029] Distillation under reduced pressure: raise the reaction temperature to 97°C, vacuumize and reduce pressure, and distill and stir for 1 hour until the reactant appears milky white;

[0030] Cooling and stirring: Stop heating and vacuum decompression, reduce the stirring speed to 300 rpm, and continue stirring for 3 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the reaction temperature ...

Embodiment 2

[0036] Platinum catalyst emulsification: 8 grams of Custer platinum catalysts with a concentration of 1500ppm, 100 grams of distilled water and 4 grams of gum arabic are placed in a three-necked flask with a stirrer, and stirred for 1 hour at a speed of 2000 rpm to obtain oil- water emulsion;

[0037] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 70°C, keep the stirring speed at 2000 rpm, gradually add 200 grams of polyethylene glycol with an average molecular weight of 15000 to the oil-water emulsion alcohol;

[0038] Distillation under reduced pressure: raise the reaction temperature to 95°C, vacuumize and reduce pressure, and distill and stir for 1.5 hours until the reactant appears milky white;

[0039] Cool down and stir: Stop heating and vacuum decompression, reduce the stirring speed to 500 rpm, and continue stirring for 2 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the rea...

Embodiment 3

[0045] Platinum catalyst emulsification: 3 grams of Custer platinum catalyst with a concentration of 5000ppm, 100 grams of distilled water and 2 grams of gum arabic were placed in a three-necked flask with a stirrer, and stirred for 0.5 hour at a speed of 3500 rpm to obtain oil- water emulsion;

[0046] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 75°C, keep the stirring speed at 3500 rpm, gradually add 300 grams of polyethylene glycol with an average molecular weight of 5000 to the oil-water emulsion alcohol;

[0047] Distillation under reduced pressure: raise the reaction temperature to 90°C, vacuumize and reduce pressure, and distill and stir for 2.5 hours until the reactant appears milky white;

[0048] Cool down and stir: Stop heating and vacuum decompression, reduce the stirring speed to 800 rpm, and continue stirring for 1.5 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com