High-energy silicon-carbon composite negative electrode material for lithium ion battery and manufacturing process thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of high production cost, difficulty in large-scale commercial use, and unsatisfactory properties, and achieves improved coating uniformity and spherical integrity. The effect of improving cycle stability and long charge-discharge platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

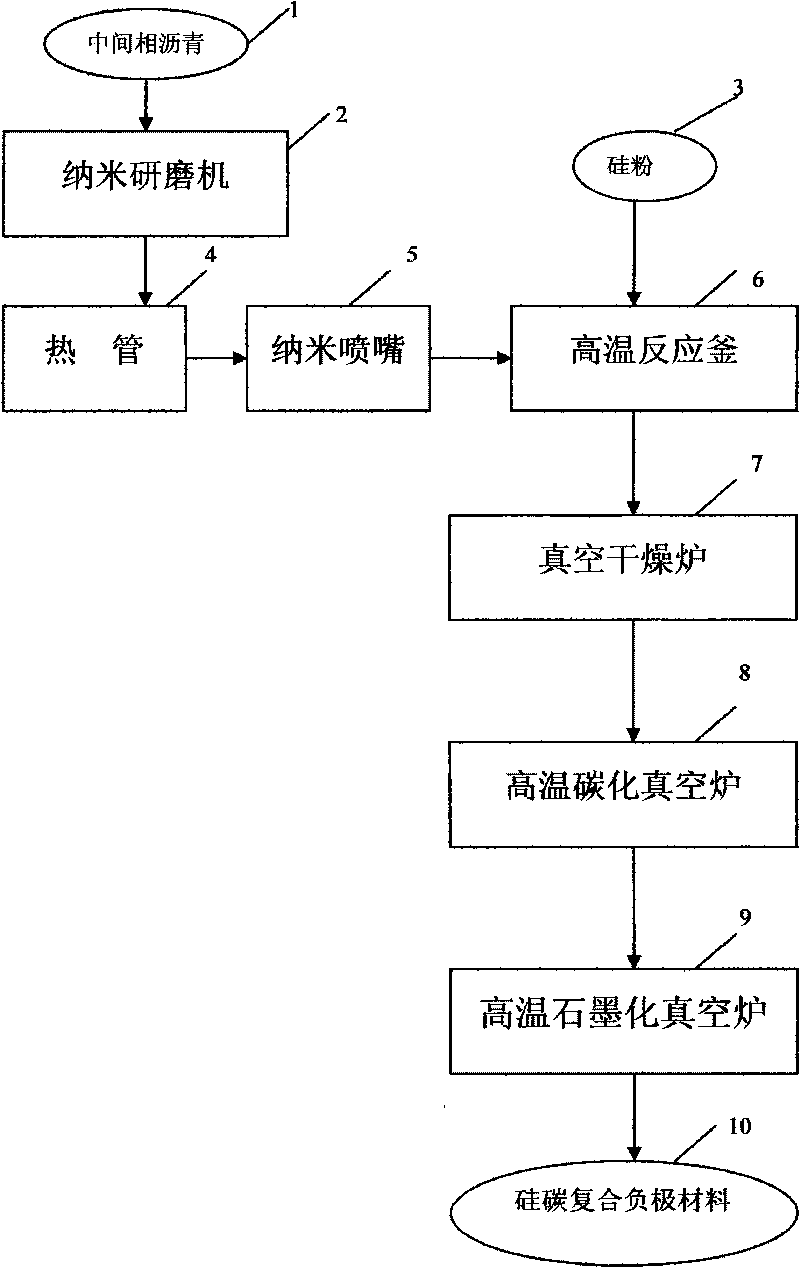

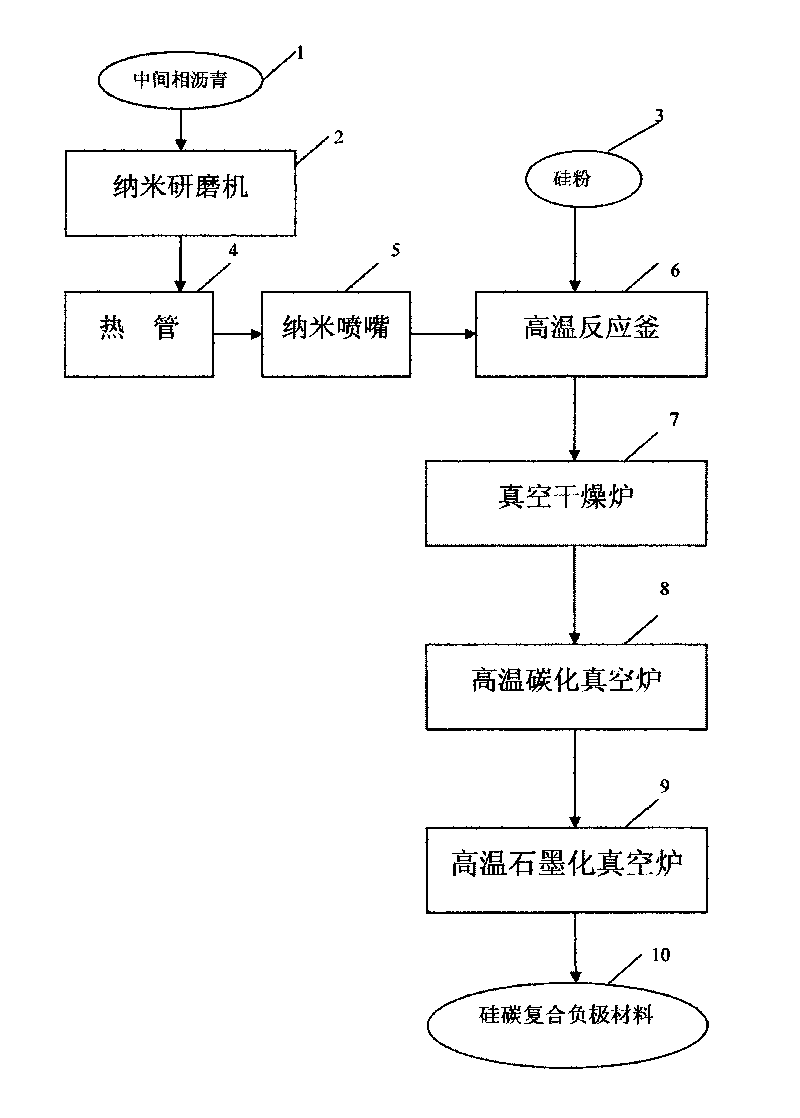

[0034] The equipment composition of this example is as attached figure 1 shown. The whole set of equipment is connected through pipelines and is in a fully sealed state. Among them, the nano-grinding machine is DRAIS PML-H / V universal nano-grinding machine.

[0035] First, 20 kg of monocrystalline silicon powder is put into the high-temperature reactor 6, and the high-temperature reactor is filled with a mixed gas of helium, neon, and argon. rate, heated for 4 hours, and the temperature in the high-temperature reactor was raised to 400°C. Monocrystalline silicon powder is dried in a high-temperature reactor, and a very small amount of pollutants are also burned clean. After 4 hours of heating, cool the high-temperature reactor to 240°C, which is close to but not more than the softening point of the nano-scale mesophase pitch, so that the single crystal silicon powder can be mixed with the sprayed nano-scale mesophase pitch droplets. Better mix coverage.

[0036] Simultane...

Embodiment 2

[0042] The drying of silicon powder in this embodiment, the formation and semi-liquidization of nano-scale mesophase pitch, the mixing and coating of nano-scale mesophase pitch and silicon powder are the same as in Example 1, but when the coated silicon powder is carbonized , the carbonization temperature is 1300°C, and the graphitization temperature is 3000°C. The obtained coated silicon powder is used as a negative electrode material for secondary batteries, and its initial charge capacity (mAh / g) is 1180.77, and its initial discharge capacity (mAh / g) is 1126.38 , 500 cycle capacity retention was 81.7%.

Embodiment 3

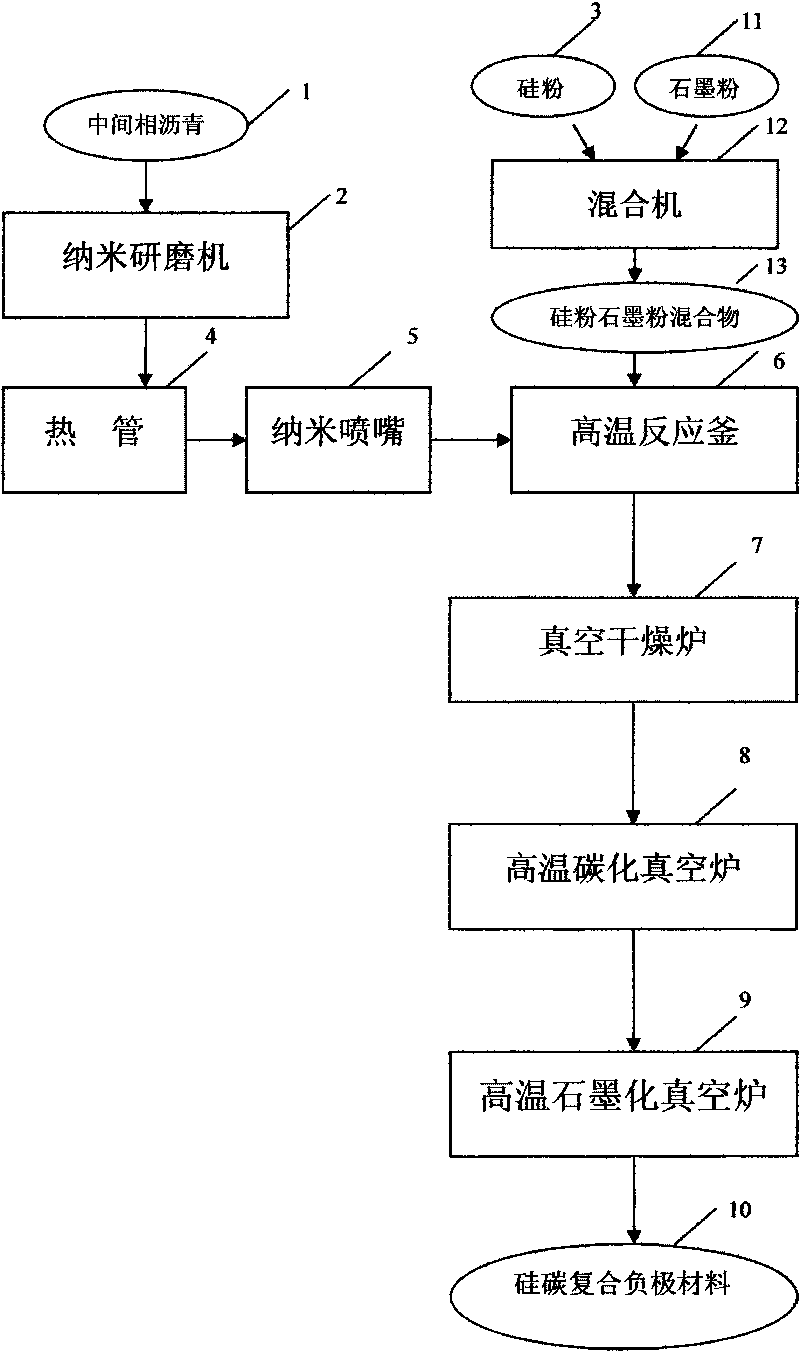

[0044] The equipment composition of this example is as attached figure 2 shown.

[0045] First put 80 kg of spherical graphite with a purity of 99.999% and 10 kg of silicon powder with a purity of 99.9% into the mixer, mix thoroughly for 3 hours, then put the mixture into the high-temperature reactor 6, and fill the high-temperature reactor with helium, neon and argon. Gas, the stirring speed of the high-temperature reactor is 200 rpm, and the temperature in the high-temperature reactor is raised to 400°C by heating at a rate of 100°C per hour for 4 hours. The mixture is dried in a high-temperature reactor, and very small amounts of pollutants are burned clean. After 4 hours of heating, cool down the high-temperature reactor to 240°C, which is close to but not more than the softening point of the nano-scale mesophase pitch, so that the mixture substrate can be compared with the sprayed nano-scale mesophase pitch droplets. Good mixed coating.

[0046] Simultaneously with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com