Process for preparing carbon/silicon carbide composite material

A composite material, silicon carbide technology, applied in the field of composite material preparation, can solve problems such as poor shear resistance between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Preparation of a C / SiC composite material with a puncture spacing of 2 mm and an interface phase thickness of 0.16 μm.

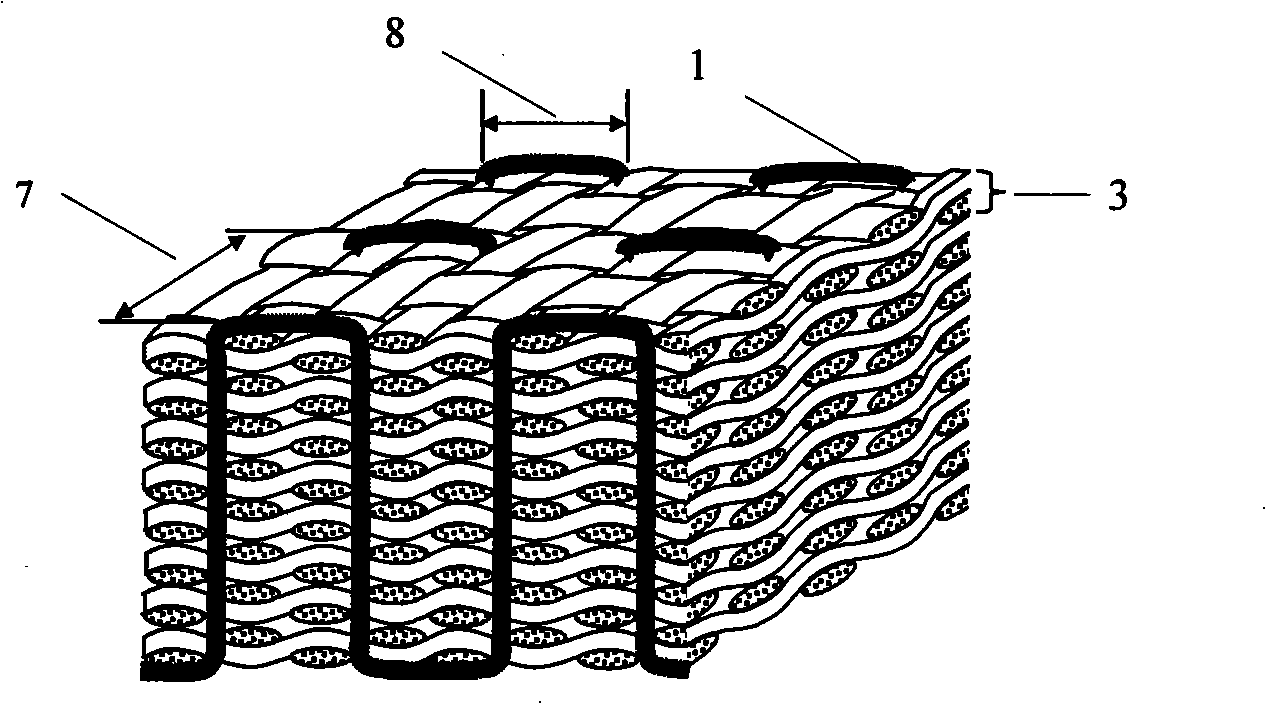

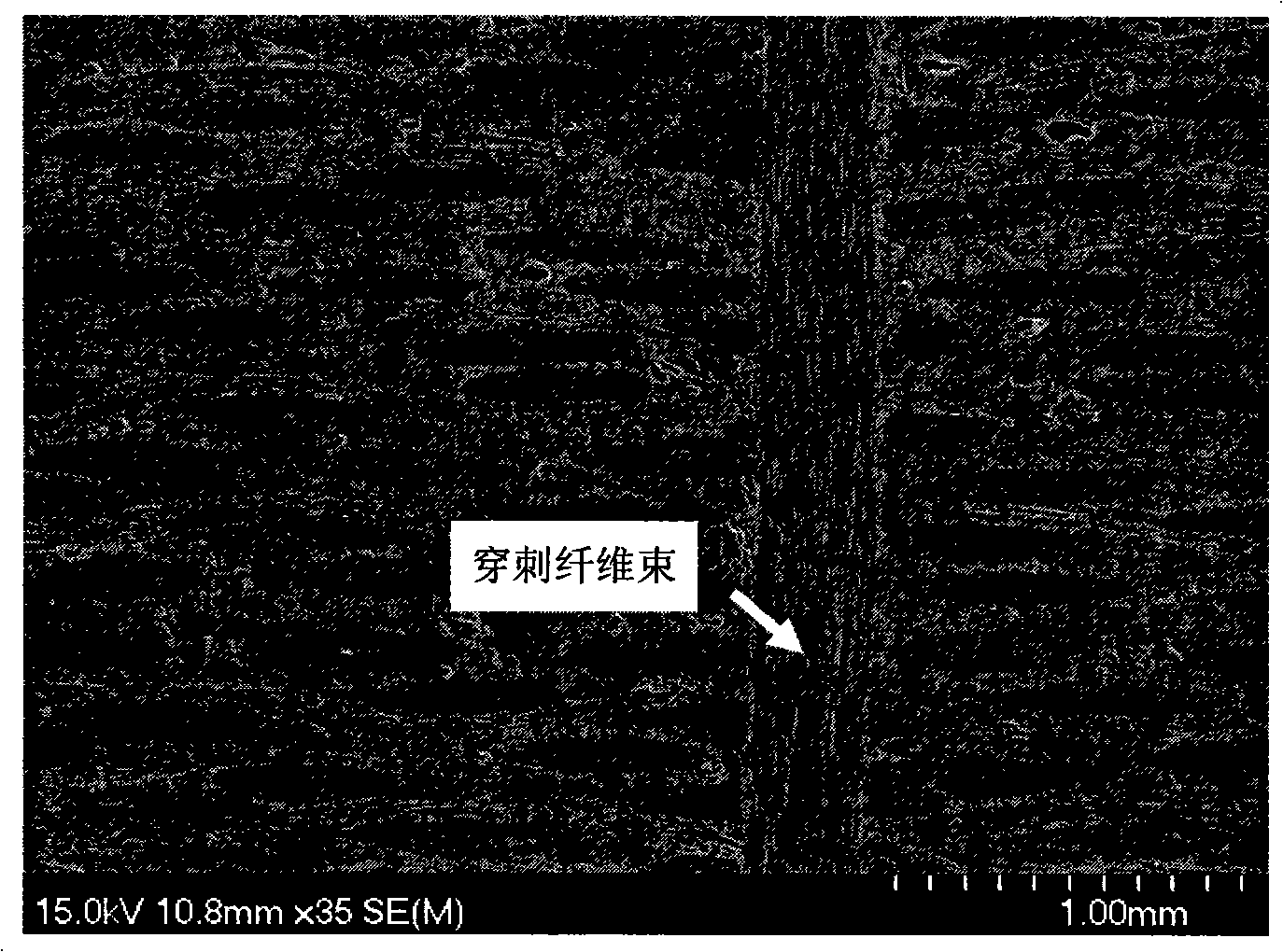

[0017] Select T300-1K carbon fiber with a diameter of 7 μm in carbon fiber 1, weave it into plain weave 3, superimpose 30 layers, and sew the laminated layers together by puncture suture method to obtain a puncture distance 7 and a puncture step length 8 of 2 mm, and a volume density of 0.70g / cm 3 1. A carbon fiber prefabricated body with a carbon fiber volume fraction of 40.0%.

[0018] The carbon fiber prefabricated body was clamped with a graphite clamp, and placed in a vacuum furnace for degumming and pretreatment at 1800 ° C for 3 h.

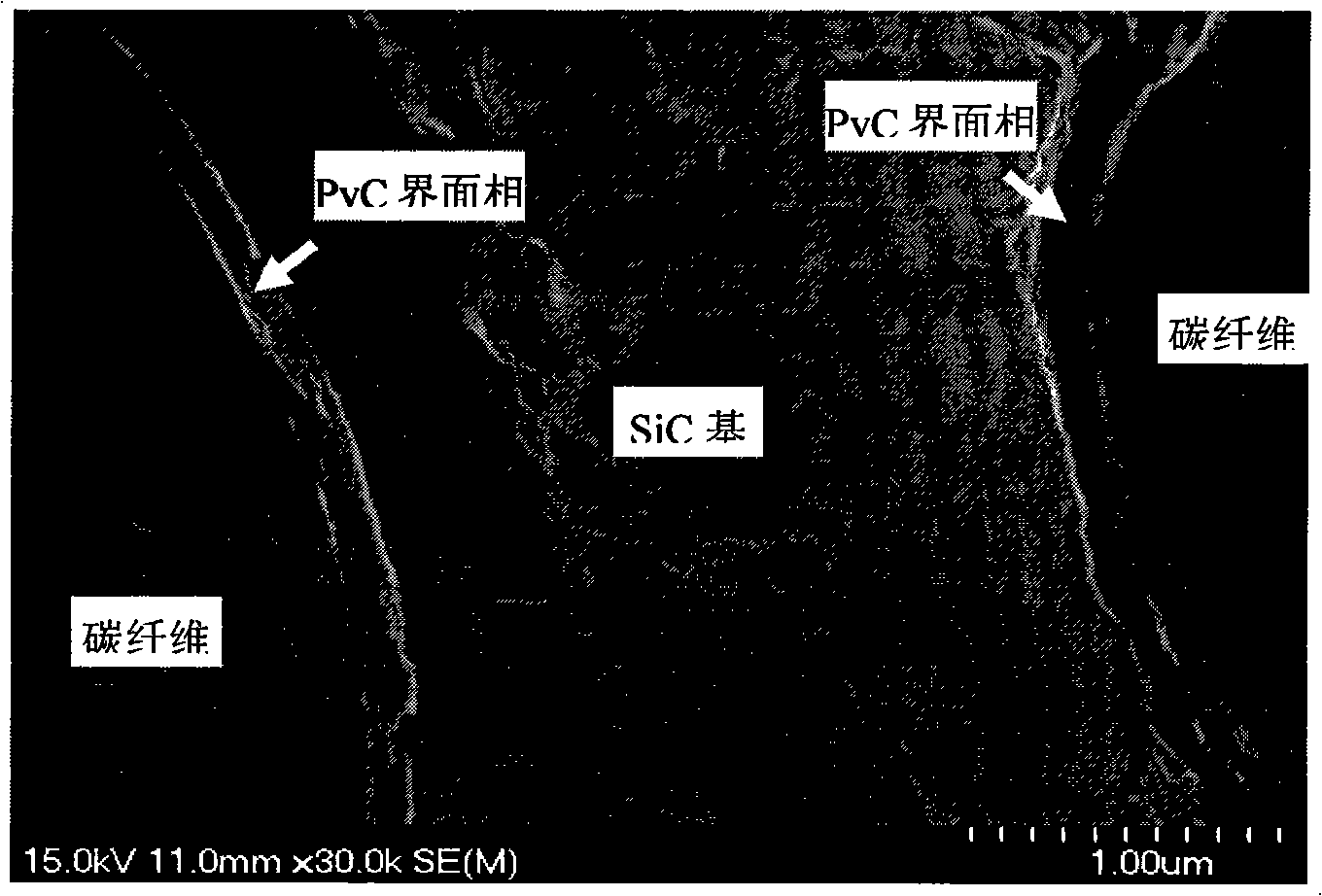

[0019] The resulting fiber preforms were deposited with PyC using CVI. The preparation of the PyC interfacial phase uses propylene as the source gas, Ar as the diluent gas, and H 2 It is the carrier gas, the deposition temperature is 900°C, and the total system pressure is 5KPa. Get a density of 0.80...

Embodiment 2

[0023] Example 2: Preparation of a C / SiC composite material with a puncture spacing of 4 mm and an interface phase thickness of 0.2 μm.

[0024] Select T300-1K carbon fiber with a diameter of 7 μm in carbon fiber 1, weave it into plain weave 3, superimpose 40 layers, and sew the stacked layers together by puncture suture method, and obtain the puncture distance 7 and puncture step length 8, both of which are 4mm, and the volume density is 0.73g / cm 3 , A carbon fiber preform with a carbon fiber volume fraction of 41.7%.

[0025] The carbon fiber prefabricated body was clamped with a graphite clamp, and placed in a vacuum furnace for degumming and pretreatment at 1900°C for 2.5 hours.

[0026] The resulting fiber preforms were deposited with PyC using CVI. The preparation of the PyC interfacial phase uses propylene as the source gas, Ar as the diluent gas, and H 2 It is the carrier gas, the deposition temperature is 950°C, and the total system pressure is 5KPa. The obtained ...

Embodiment 3

[0031] Example 3: Preparation of a C / SiC composite material with a puncture distance of 6 mm and an interface phase thickness of 0.2 μm.

[0032] Select T300-1K carbon fiber with a diameter of 7 μm in carbon fiber 1, weave it into plain weave 3, superimpose 55 layers, and sew the laminated layers together by puncture suture method, and obtain the puncture distance 7 and puncture step length 8 of 6 mm, and the volume density is 0.71g / cm 3 , A carbon fiber prefabricated body with a carbon fiber volume fraction of 40.3%.

[0033] The carbon fiber prefabricated body was clamped with a graphite clamp, and placed in a vacuum furnace at 2100°C for 2 hours of degumming and pretreatment.

[0034] The resulting fiber preforms were deposited with PyC using CVI. The preparation of the PyC interfacial phase uses propylene as the source gas, Ar as the diluent gas, and H 2 It is the carrier gas, the deposition temperature is 1000°C, and the total system pressure is 7KPa. The resulting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com