Pyrolytic hard carbon material and application thereof

A technology for pyrolysis of hard carbon and negative electrode materials, applied in the field of materials, can solve the problems of large mass loss, low carbon content, and high cost of hard carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

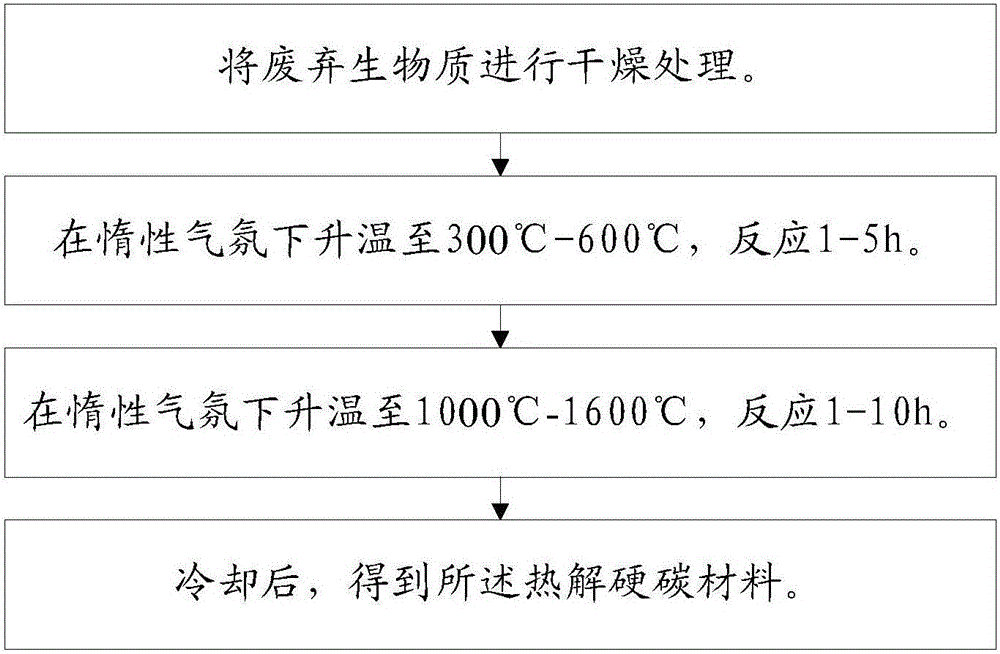

[0038] Embodiment 1 of the present invention provides a kind of pyrolysis hard carbon material, and its preparation method is as follows figure 1 shown, including the following steps:

[0039] (1) Dry the waste biomass.

[0040] Specifically, waste biomass is used as a hard carbon precursor, that is, waste biomass is used as a raw material to prepare pyrolytic carbon materials. Preferably, the waste biomass can be selected from one or more of corn cobs, corn residues, corn stalks and corn husks. In order to remove the moisture in the hard carbon precursor, dry the hard carbon precursor, for example, place the hard carbon precursor in an oven at 50-120°C for 20-30 hours to remove the moisture in the hard carbon precursor. moisture. It should be pointed out that, in order to facilitate drying and subsequent heat treatment, the hard carbon precursor can be pre-pulverized before drying the hard carbon precursor.

[0041] (2) Raise the temperature to 300°C-600°C under an inert ...

Embodiment 2

[0054] Preparation of pyrolytic hard carbon material: cut the corn cobs with the corn kernels removed into small pieces about 1 cm wide, put them in a beaker, and bake them in a constant temperature oven at 80°C for 26 hours. After drying, put it in a porcelain boat of about 5cm*2cm*2cm, ready for high-temperature carbonization.

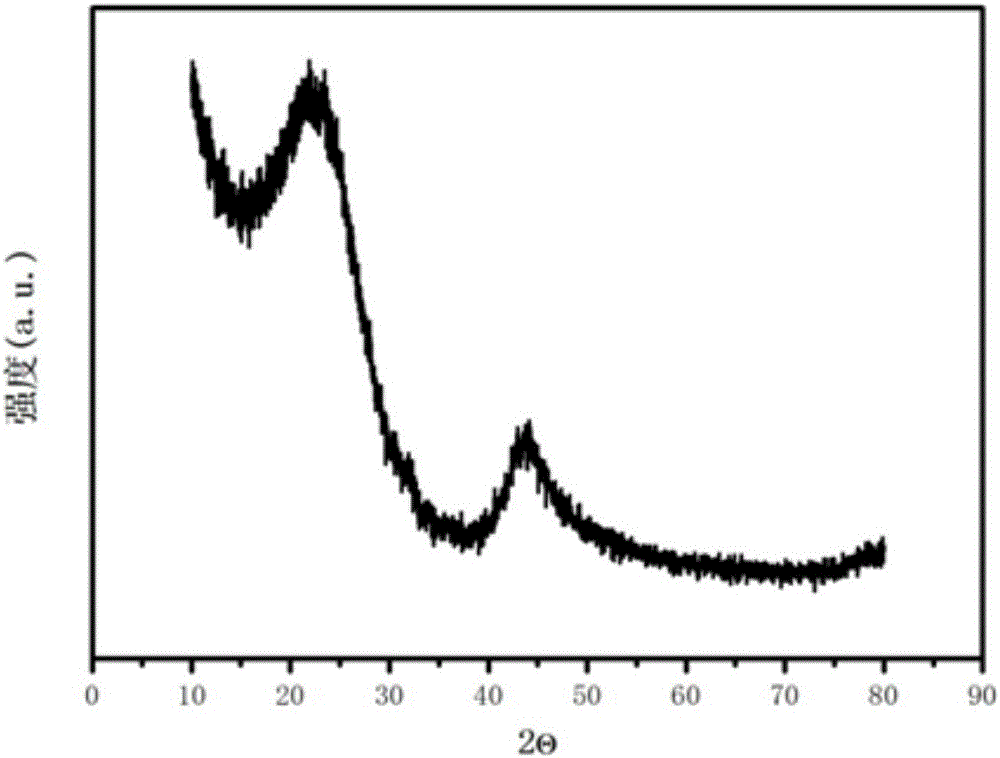

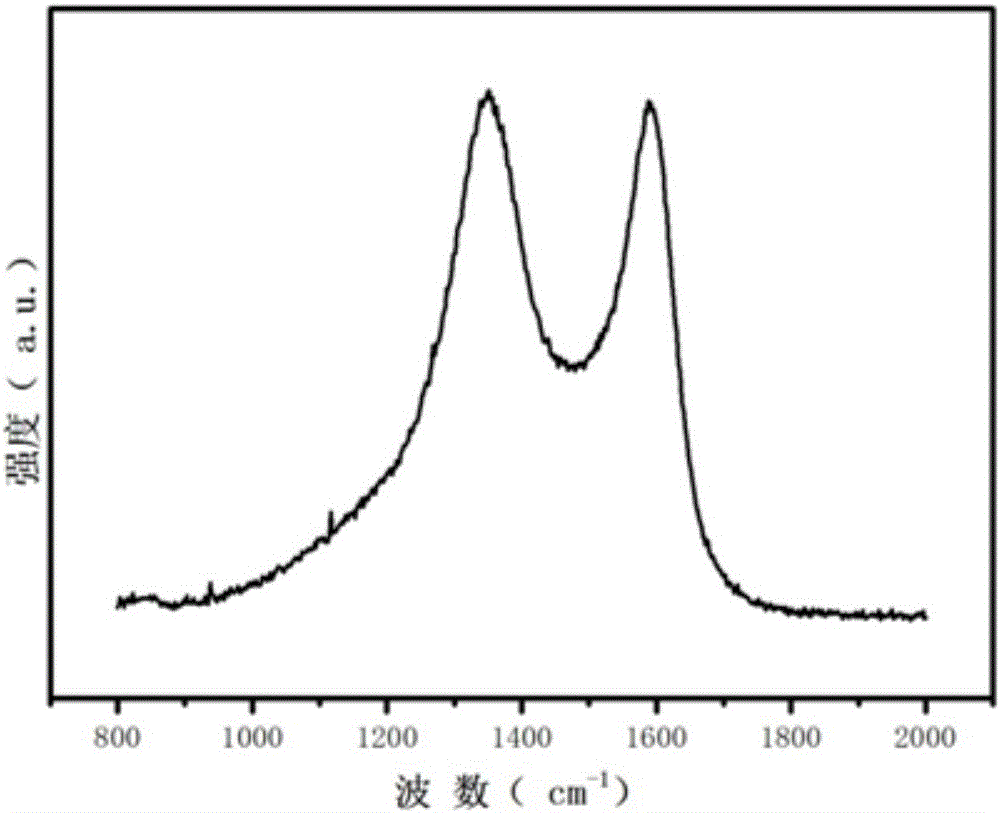

[0055] Put the corn cob together with the porcelain boat in a tube furnace (the tube is about 100 cm long and 6 cm in diameter, the same tube furnace is used in the following examples), and under the protection of argon, the temperature is raised to 500 °C at a rate of 1 °C / min , with an argon flow rate of 25mL / min, pre-carbonize at 500°C for 2h, then raise the temperature to 1300°C at a rate of 5°C / min, keep the temperature for 2h, and then cool down to room temperature naturally. The carbonized corn segments are taken out and ground into powder in a mortar to obtain pyrolysis hard carbon products. Its X-ray diffraction (XRD) pattern see figure 2...

Embodiment 3

[0060] Preparation of pyrolytic hard carbon material: cut the corncobs from which the corn kernels have been removed into small pieces with a width of about 1 cm, put them in a beaker, and dry them in a constant temperature oven at 50°C for 30 hours. After drying, put it in a porcelain boat of about 5cm*2cm*2cm, ready for high-temperature carbonization.

[0061] Put the corn cob together with the porcelain boat in a tube furnace, under the protection of argon, the temperature was raised to 500°C at a rate of 1°C / min, the flow of argon gas was 25mL / min, preheated at 500°C for 2h, and then heated at 500°C for 5 The temperature was raised to 1000°C at a rate of °C / min, kept for 2 hours, and then cooled to room temperature naturally. The carbonized corncobs are taken out and ground into powder in a mortar to obtain pyrolysis hard carbon products. Its X-ray diffraction (XRD) pattern see Image 6 . The d of the hard carbon material can be obtained from the XRD pattern 002 = 0.40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com