Triso fuel for high burn-up nuclear engine

a nuclear engine and high-burning technology, applied in nuclear reactors, nuclear elements, greenhouse gas reduction, etc., can solve the problems of significant technical challenges to achieve an economy and difficult long-term sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

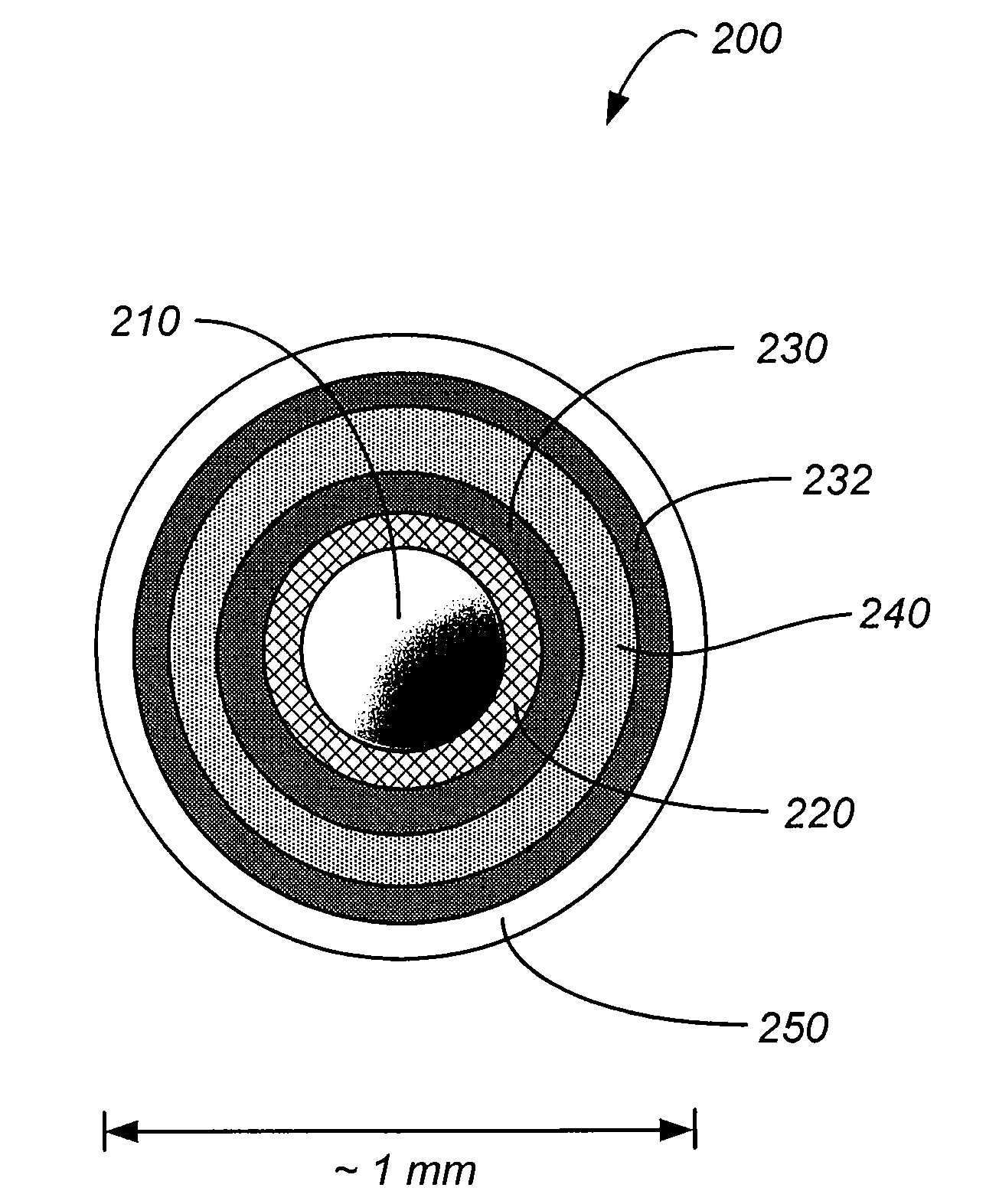

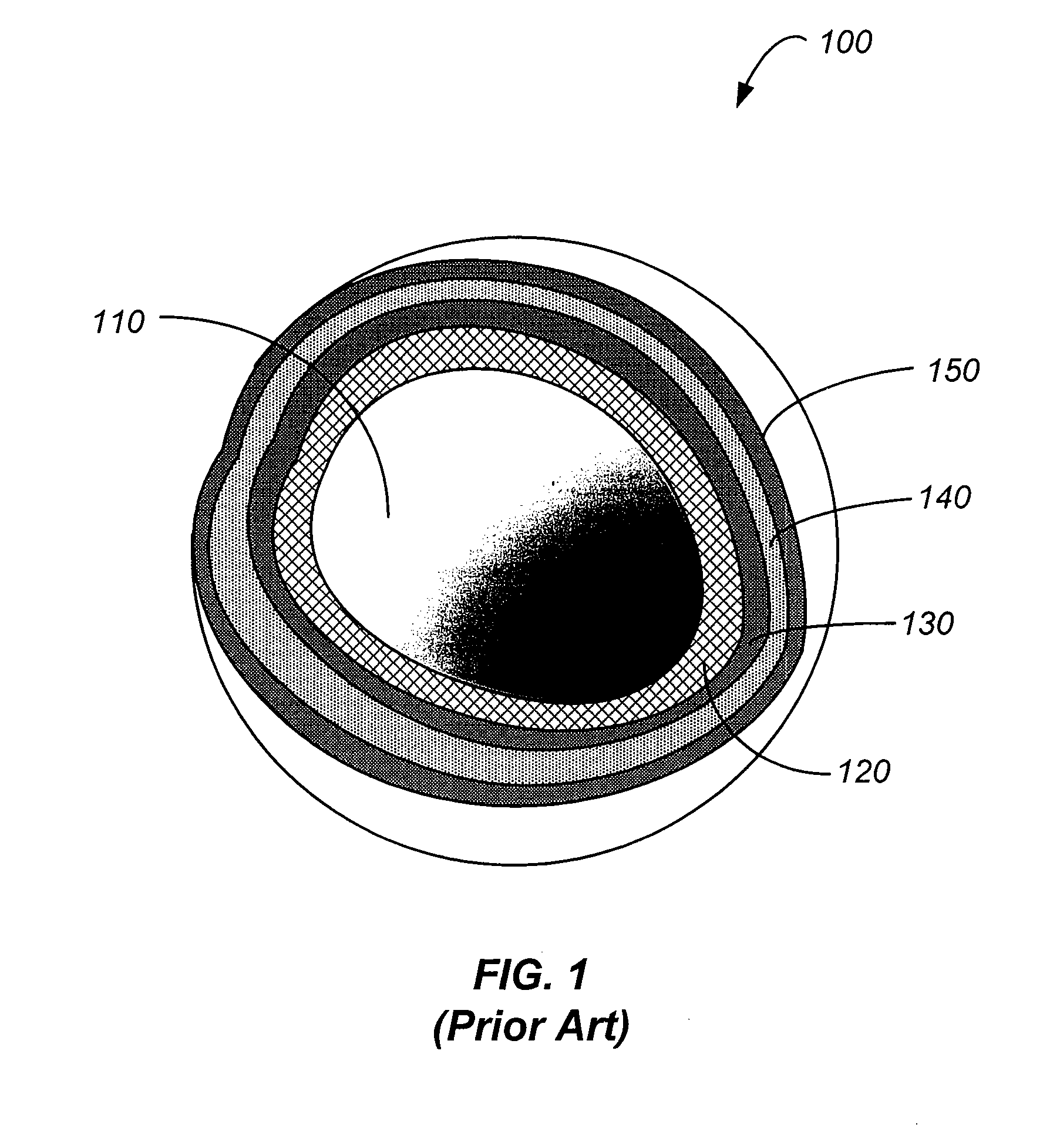

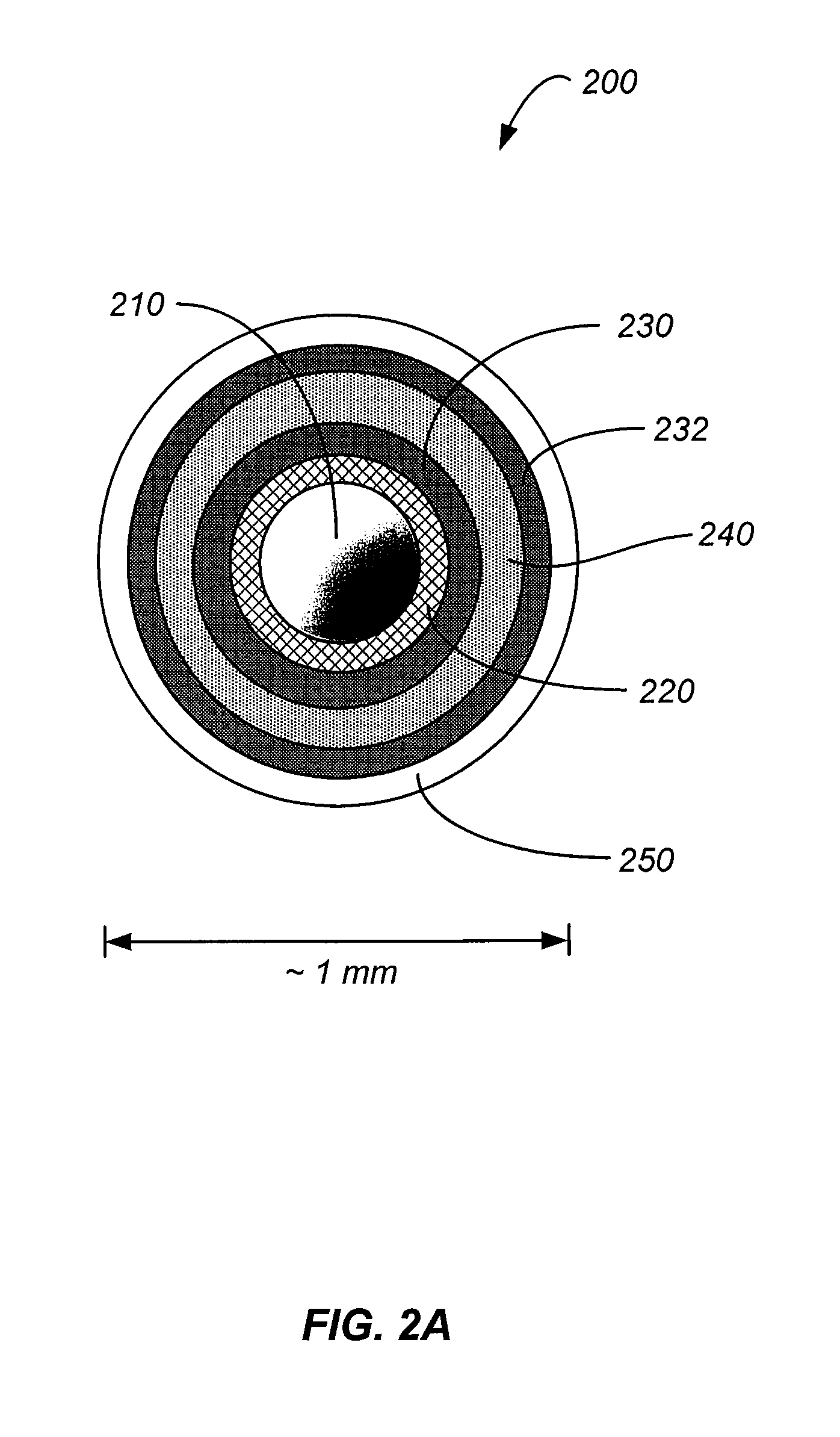

[0023]According to the present invention, techniques related to nuclear engine fuel are provided. More particularly, an embodiment of the present invention provides an enhanced fuel particle suitable for use in a laser inertial confinement fusion-fission power plant. Such an engine is described in more detail in our commonly assigned copending U.S. patent application Ser. No. ______, entitled “Control of a Laser Inertial Confinement Fusion-Fission Power Plant,” filed contemporaneously with this application, the contents of which are incorporated by reference. Merely by way of example, the invention has been applied to the design and fabrication of a robust tristructural-isotropic (TRISO) particle capable of high burn-up as well as a fuel pebble including a plurality of the robust TRISO particles. The methods and systems described herein are also applicable to other nuclear power plant designs. Additional discussion related to nuclear fusion-fission engines is provided in U.S. patent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com