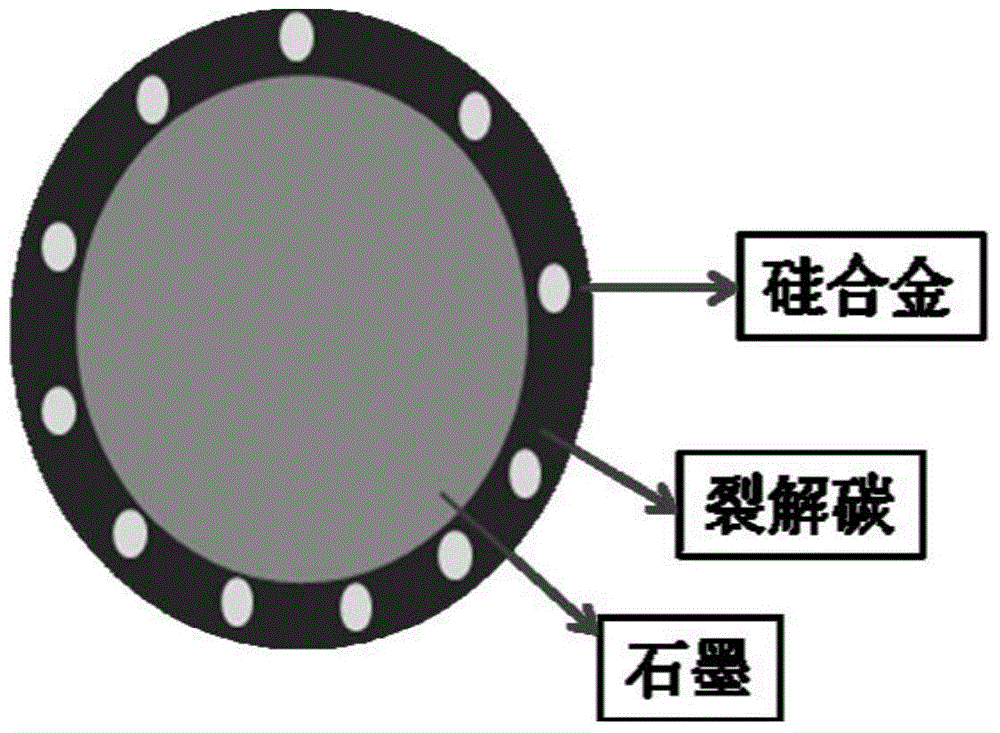

Silicon alloy composite anode material, preparation method and lithium ion battery

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity and first effect, poor material consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

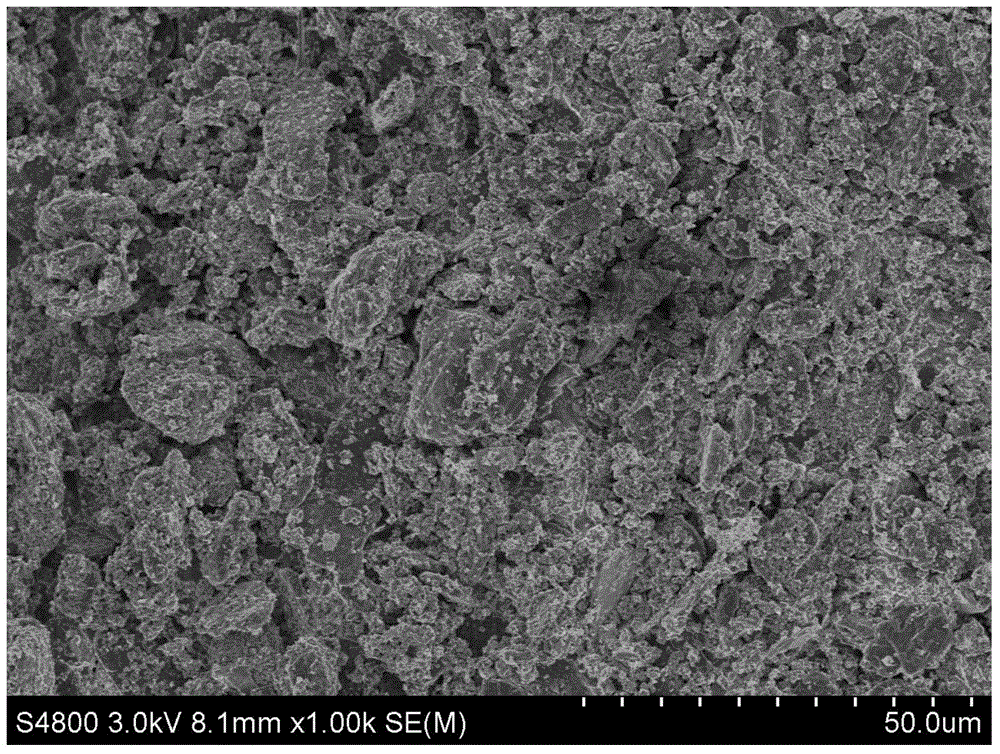

Examples

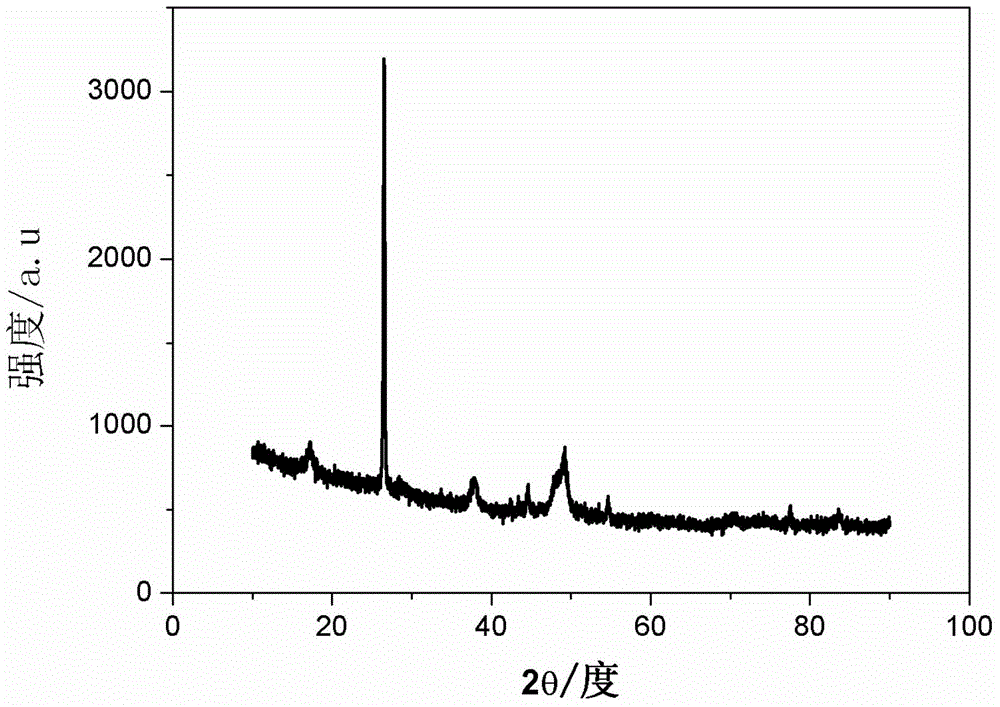

Embodiment 1

[0072] (1) Mix Fe powder with a median particle size of 10 μm and silicon powder with a median particle size of 3 μm at a molar ratio of Fe:Si=1:2, mix them, and then place the mixed powder in a stainless steel tank , select the quenched steel ball 5mm, pass into the argon gas. Ball milling was carried out on a planetary ball mill, wherein the rotational speed of the ball mill was 500r / min, the mass ratio of the balls to the mixed powder was 50:1, and the ferrosilicon alloy was obtained after ball milling for 50 hours.

[0073] (2) Proportion the ferrosilicon alloy powder obtained in step (1) and spherical natural graphite with a particle size of 5-20 μm in a mass ratio of 10:80, mix them and place them in mechanical fusion, and adjust the rotating speed to 3000.0r / min , the tool gap width is 0.01cm, the fusion is 1.0h, and the precursor is obtained.

[0074] (3) Proportion the precursor powder obtained in step (2) and pitch with a particle size of 5-10 μm (the final cracked ...

Embodiment 2

[0077] (1) Mix Cu powder with a median particle size of 100 μm and silicon powder with a median particle size of 0.05 μm at a molar ratio of Cu:Si=2:1, mix them, and then place the mixed powder in a stainless steel tank , select the quenched steel ball 20mm, pass into the argon to. Ball milling was carried out on a planetary high-energy ball mill, wherein the speed of the ball mill was 1000r / min, the mass ratio of the balls to the powder was 200:1, and the silicon-copper alloy was obtained after ball milling for 40 hours.

[0078] (2) the silicon-copper alloy powder obtained in the step (1) and particle diameter are 5-20 μ m spherical artificial graphite to carry out proportioning by mass ratio 50:10, place in the stainless steel tank after mixing, select hardened steel ball 3mm for use, Bubble argon. Mixing was carried out on a planetary high-energy ball mill, wherein the speed of the ball mill was 100r / min, the mass ratio of the balls to the powder was 10:1, and the ball mi...

Embodiment 3

[0081] (1) The silicon-titanium alloy powder with a median particle size of 0.1 μm and the silicon powder with a median particle size of 30 μm are dispersed in an acetone solvent at a molar ratio of Ti-Si:Si=2:1, and then Put the slurry into a sand mill for ball milling, wherein the balls are 0.1mm zirconium balls, the speed of the ball mill is 1500r / min, the mass ratio of the balls to the powder is 10:1, and after 5 hours of ball milling, silicon-titanium alloy slurry is obtained .

[0082](2) Mix the silicon-titanium alloy slurry obtained in step (1) with spherical natural graphite with a particle size of 5-20 μm in a mass ratio of 20:50, and then spray dry to obtain a precursor.

[0083] (3) Place the precursor powder obtained in step (2) in a rotary furnace, adjust the rotation speed to 0.5r / min, feed nitrogen gas, raise the temperature to 800°C at a heating rate of 10.0°C / min, and then feed acetylene gas , control the acetylene gas flow rate to 1.0L / min, keep warm for 2h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com