Material defect detector and material defect detection method

A technology for material defects and detection equipment, applied in the direction of material capacitance, etc., can solve problems such as non-destructive testing of materials inside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

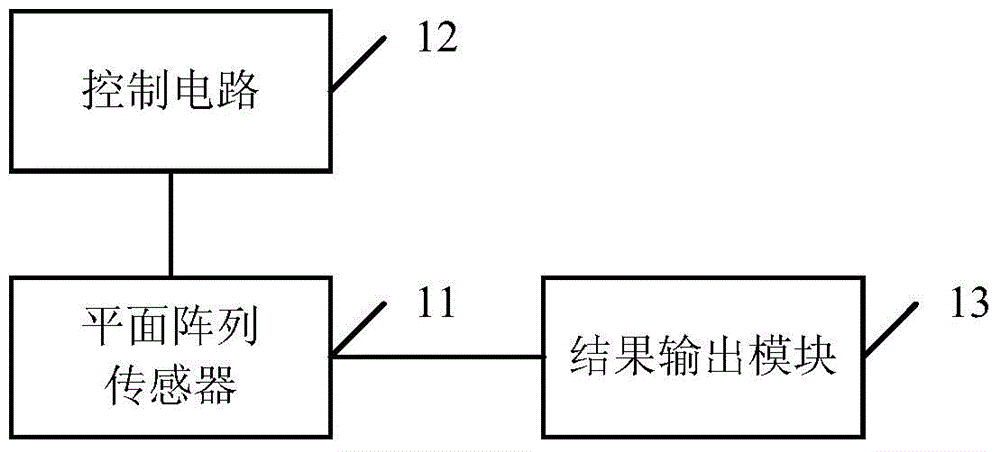

[0064] Embodiment 1 of the present invention provides a material defect detection device, such as figure 1 shown, including:

[0065] A planar array sensor 11, a control circuit 12 and a result output module 13 for detection, wherein:

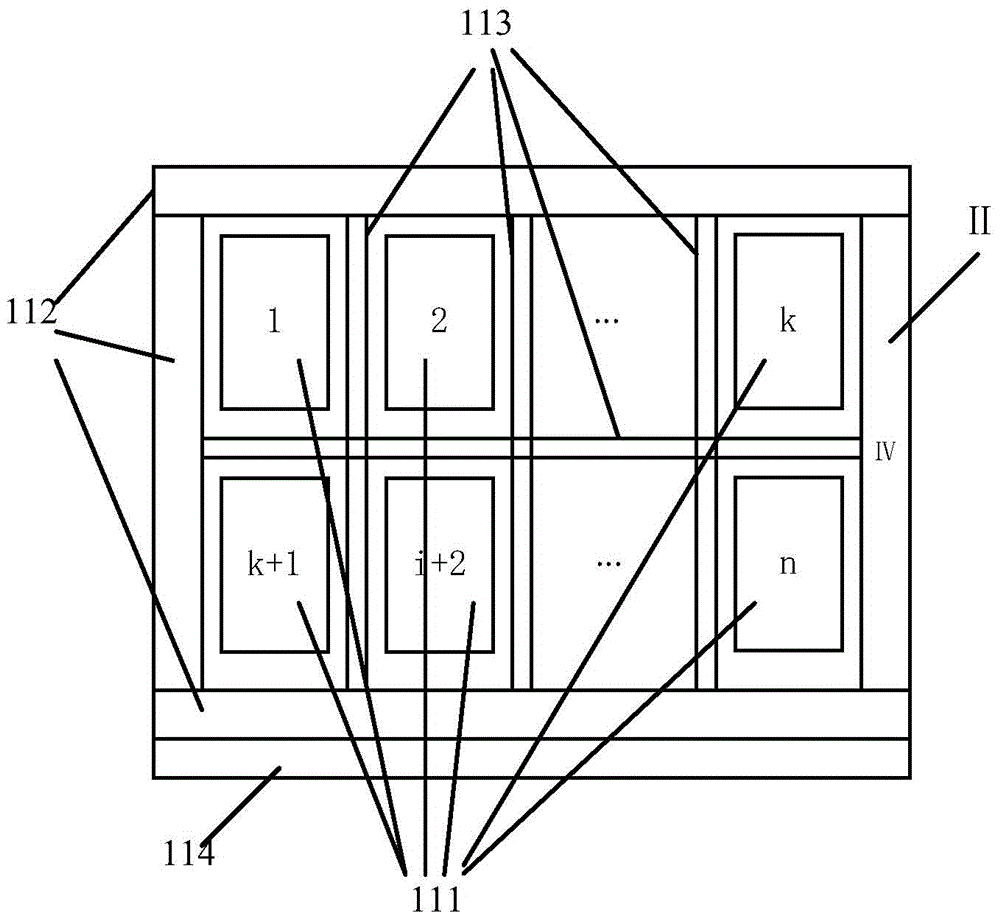

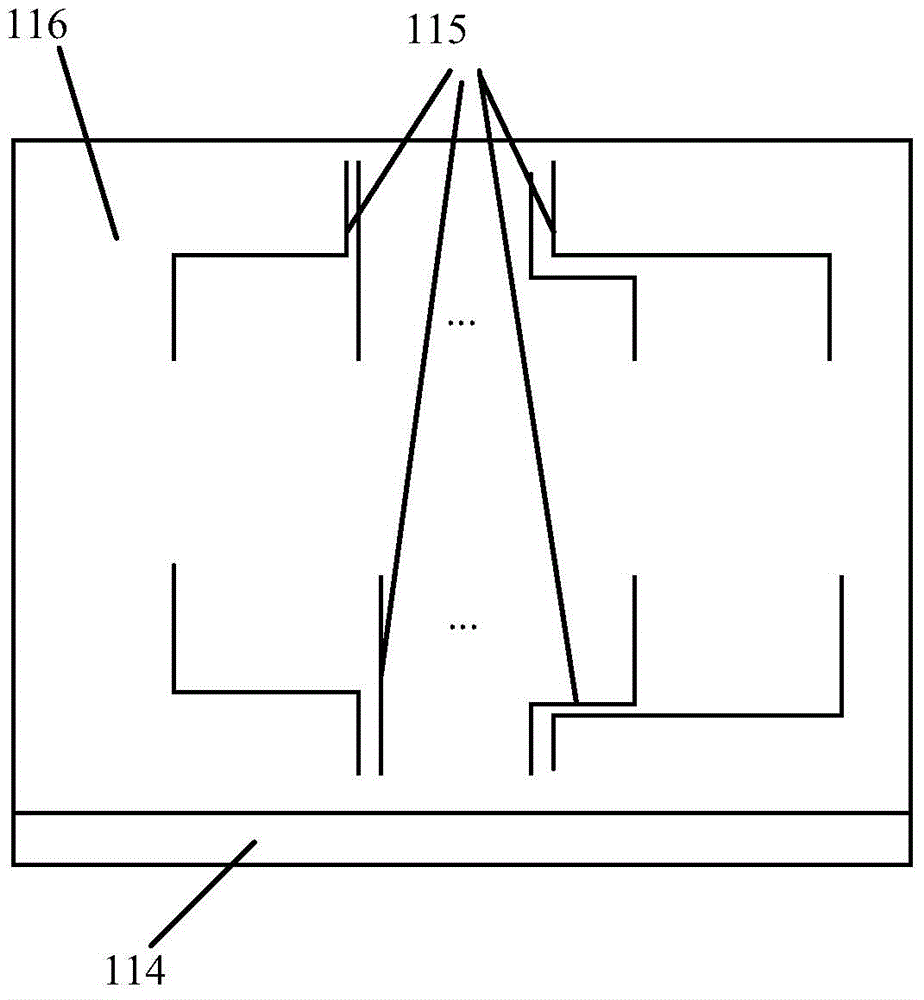

[0066] Such as Figure 2A and Figure 2B As shown, the planar array sensor includes: multiple detection electrodes 111, end shielding electrodes 112, inter-electrode shielding electrodes 113, sensor substrate 114, signal line 115 and substrate back shielding layer 116, wherein:

[0067] The control circuit 12 is connected to the plurality of detection electrodes 111, and is used to control the voltage excitation to the plurality of detection electrodes 111;

[0068] A plurality of detection electrodes 111 are arranged in an array above the sensor substrate 114, inter-electrode shielding electrodes 113 are distributed between the plurality of detection electrodes 111, end shielding electrodes 112 are distributed around the plurality of detect...

Embodiment 2

[0094] According to the same inventive concept, based on the material defect detection equipment provided in the above-mentioned embodiment 1 of the present invention, embodiment 2 of the present invention also provides a material defect detection method, such as Figure 5 shown, including:

[0095] Step 501, through the above-mentioned control circuit of the material defect detection device, sequentially perform voltage excitation on each electrode pair to be detected of the plurality of detection electrodes of the planar array sensor.

[0096] Step 502: Output a corresponding detection result according to the detection signal generated after each electrode pair to be detected is excited by the voltage.

[0097] The method provided by the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

[0098] Figure 6 The detailed flowchart of the material defect detection method provided by Embodiment 2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com