Finite element prediction system for welding and solidifying crack in virtual environment

A technology for solidification cracks and prediction systems, applied in welding equipment, material defect testing, instruments, etc., can solve problems such as difficult application, limited application of finite element numerical simulation technology, and difficulty in implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

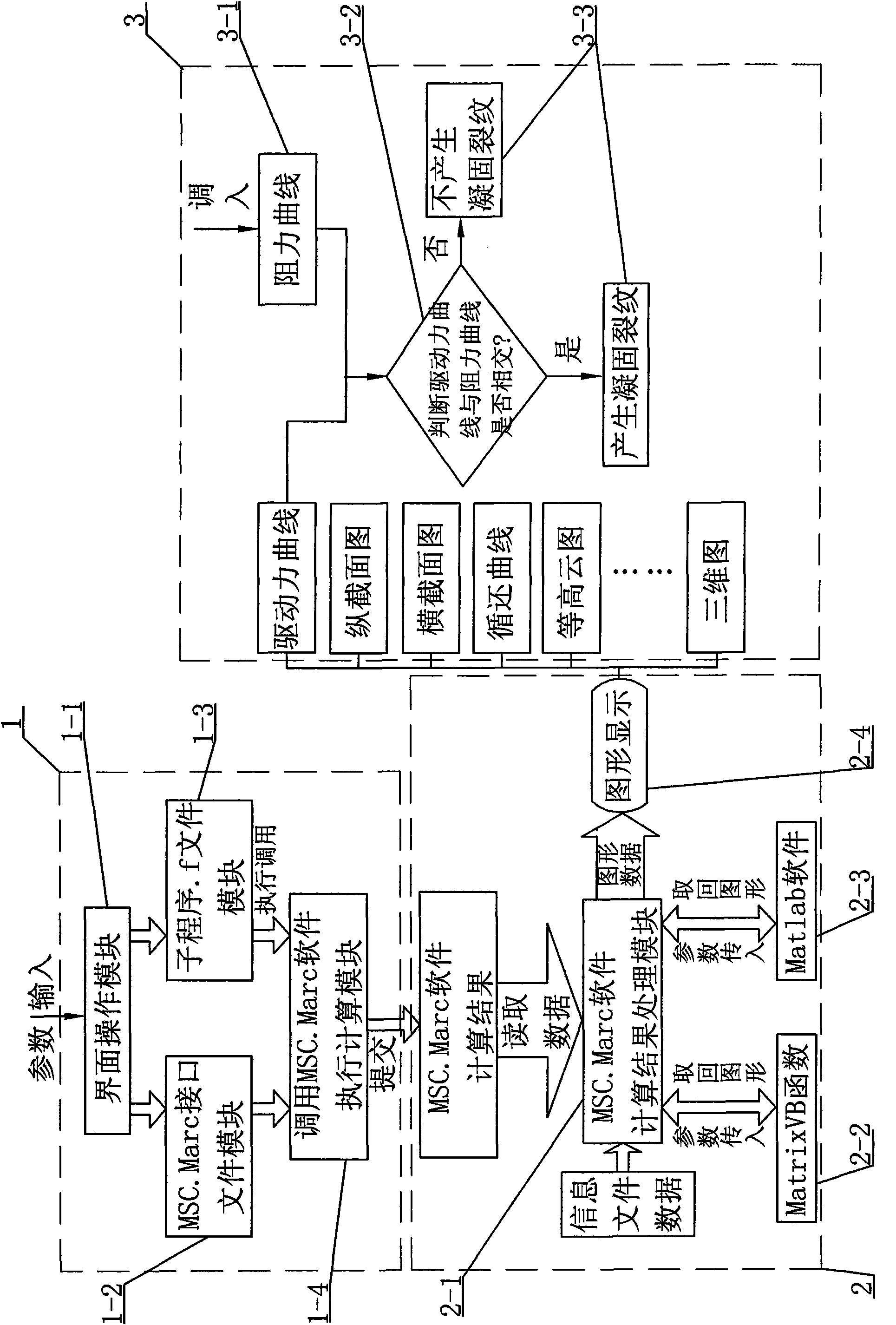

[0026] Specific implementation mode one: combine Figure 1-10 To illustrate this embodiment, the finite element prediction system for welding solidification cracks in the virtual environment described in this embodiment is composed of a pre-processing subsystem 1, a post-processing subsystem 2, and a solidification crack prediction subsystem 3;

[0027] The pre-processing subsystem 1 is composed of an interface operation module 1-1, an MSC.Marc interface file module 1-2, a subroutine.f file module 1-3 and a calling MSC.Marc software execution calculation module 1-4;

[0028] Post-processing subsystem 2 is composed of MSC.Marc software calculation result processing module 2-1, MatrixVB function module 2-2, Matlab software module 2-3 and graphic display module 2-4;

[0029] The solidification crack prediction subsystem 3 is composed of a resistance curve transfer module 3-1, a judgment module 3-2 and a result output module 3-3;

[0030]The interface operation module 1-1 is used...

specific Embodiment approach 2

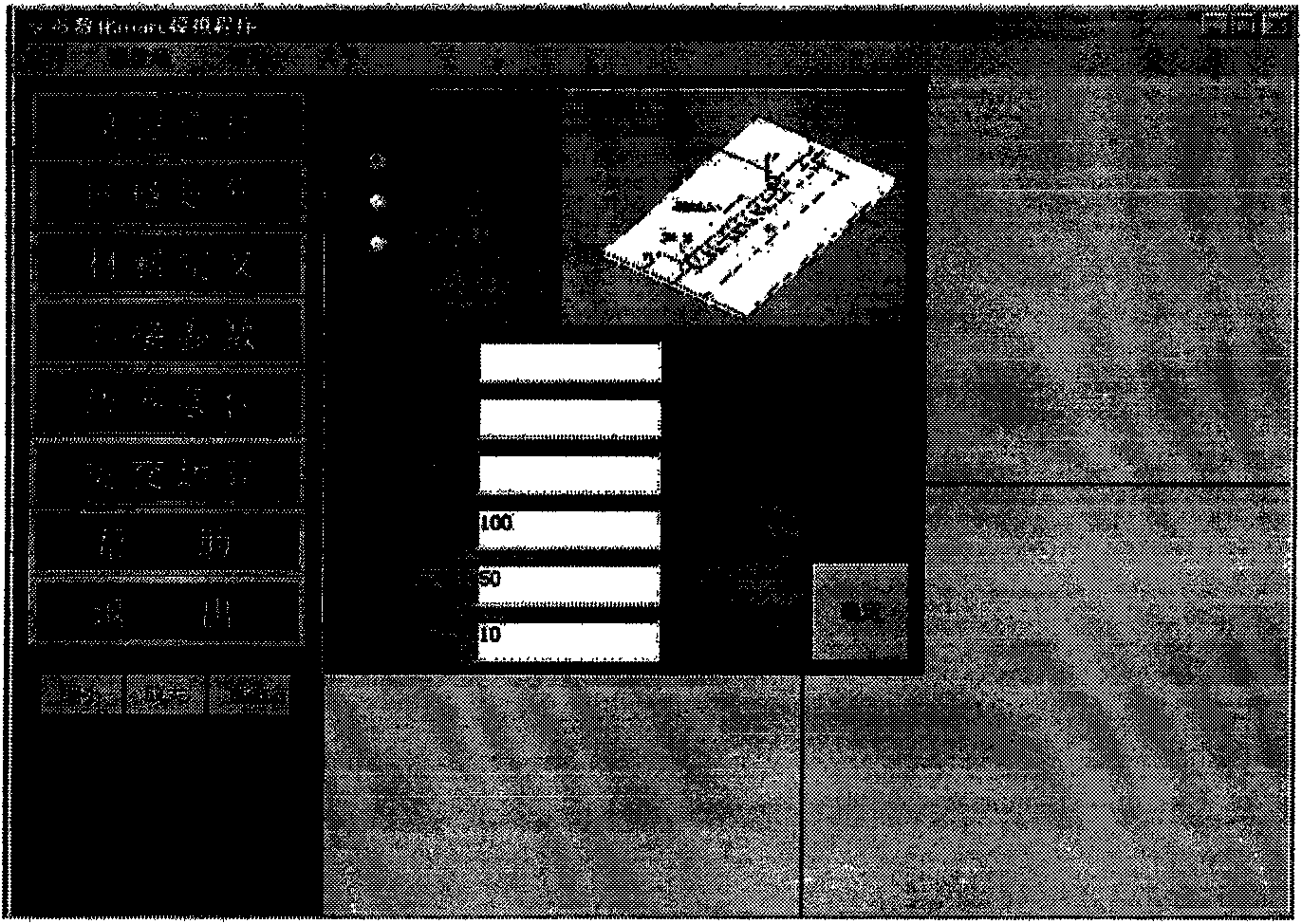

[0032] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that the interface operation module 1-1 is a Chinese interface operation module. Such setting is convenient for ordinary technicians who can only speak Chinese to operate.

specific Embodiment approach 3

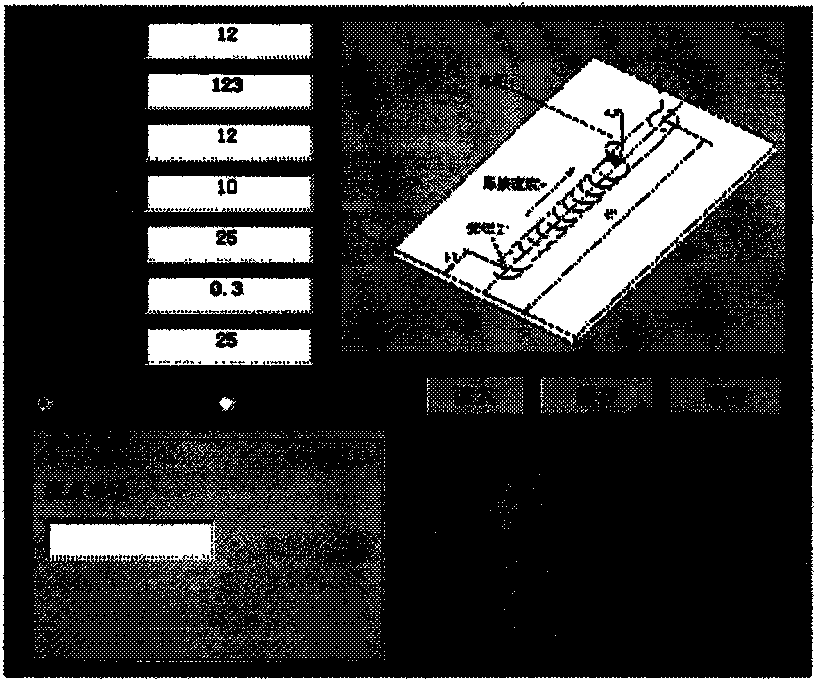

[0033] Specific implementation mode three: combination figure 2 This embodiment is described. The difference between this embodiment and the specific embodiment 1 is that the parameter structure for predicting welding solidification cracks that can be selected by the user in the prediction system is model size parameters, grid parameters, material parameters, initial Conditions, boundary conditions, welding parameters, welding heat source model parameters. According to the parameters entered by the user, the system automatically completes the creation of interface files and subroutines according to the format of the respective files, and automatically submits them, and realizes the numerical simulation calculation of the temperature field and stress / strain field of welding solidification cracks.

[0034] Model size parameters: The system provides three types of joints: butt joints, corner joints and T-joints. The parameters that need to be input are the length, width and thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com