Array attenuator for high-energy laser and manufacturing method thereof

A high-energy laser and attenuator technology, used in photometry, instruments, scientific instruments, etc., can solve problems such as limited application range, large differences in absorption coefficients, difficult parameter measurement, etc., to ensure installation accuracy, ensure consistency, The effect of improving the reflectivity of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

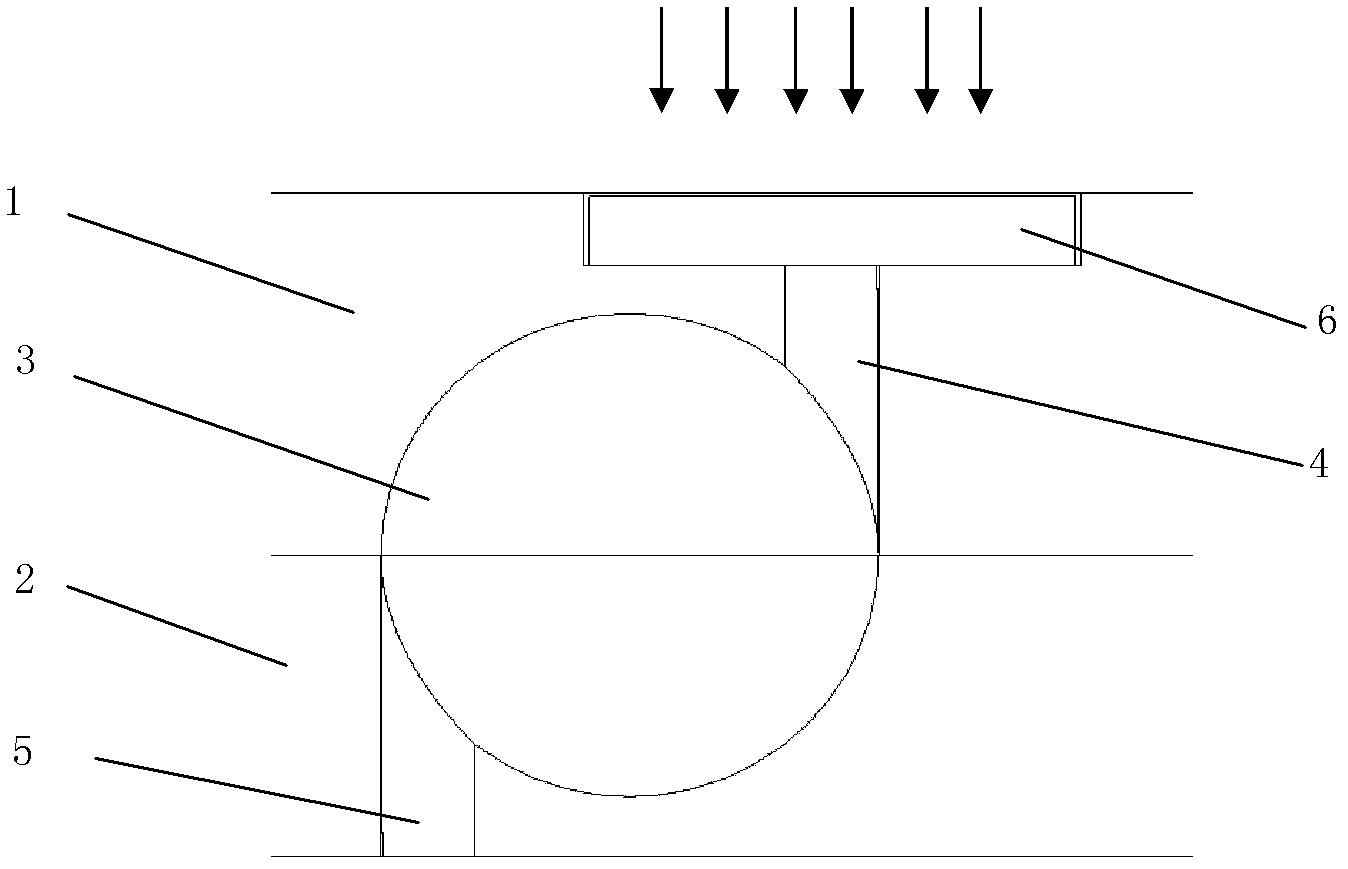

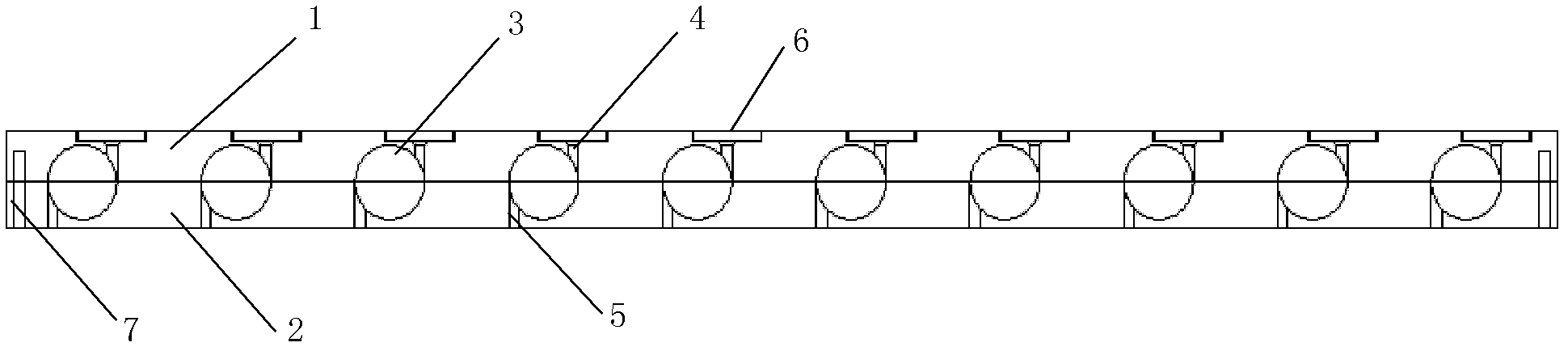

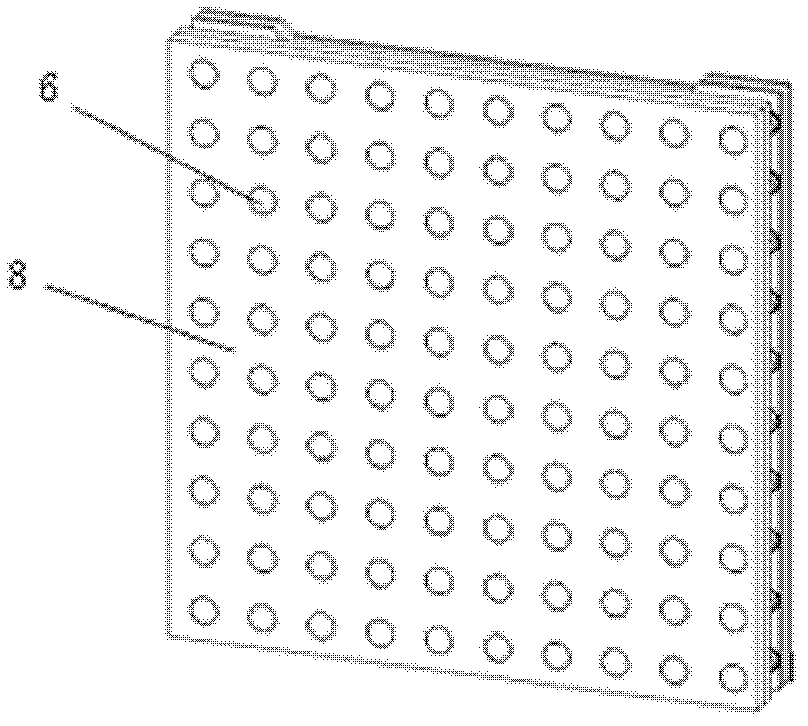

[0030] Such as figure 1 As shown, hemispherical cavities and laser coupling holes with equal diameters are respectively processed on the metal front panel 1 and rear panel 2, and the two panels are stacked together so that the corresponding hemispherical cavities are buckled together to form an integrating sphere The inner cavity 3 and two laser coupling holes are respectively located on opposite sides of the spherical cavity, tangent to the maximum diameter of the hemispherical cavity, forming a laser entrance hole 4 and a laser exit hole 5 . Laser along the test figure 1 The direction of the arrow in the middle is coupled into the cavity 3 of the integrating sphere from the laser entrance hole 4 through the optical window 6. After repeated absorption and reflection in the cavity, only a small part of the light is finally emitted from the laser exit hole 5, realizing the control of strong laser power. Density attenuation. Such as figure 2 As shown, if there are multiple i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com