Flexible printed circuit, illumination apparatus, capsule endoscope and vehicle lighting apparatus

A flexible printed circuit, conductive technology, applied in the field of lighting equipment, can solve the problems of cost increase, undisclosed and simultaneous realization of LED structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

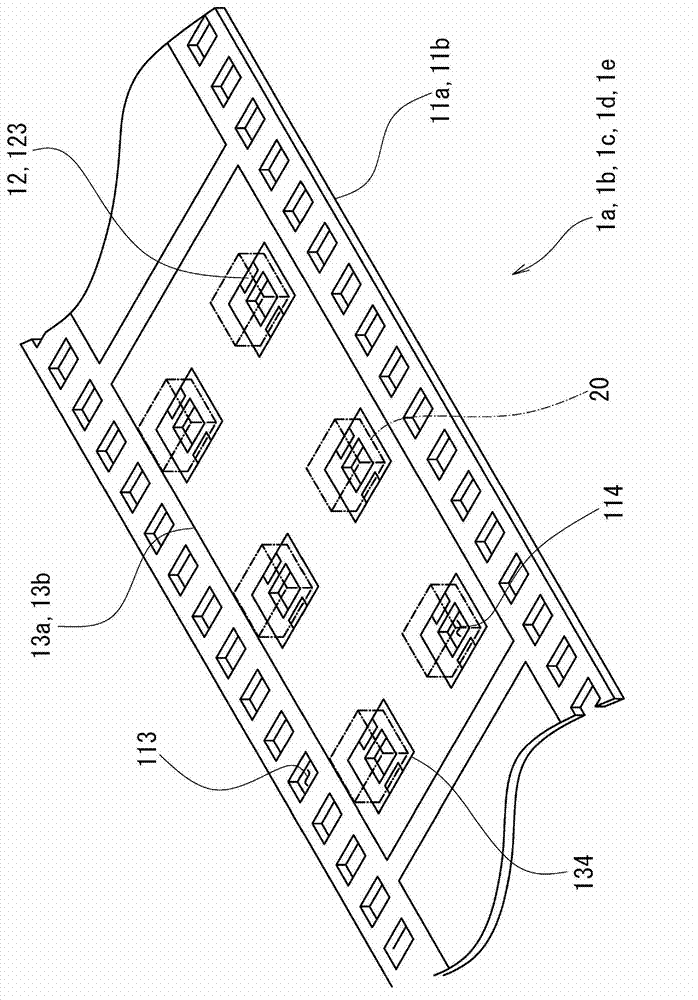

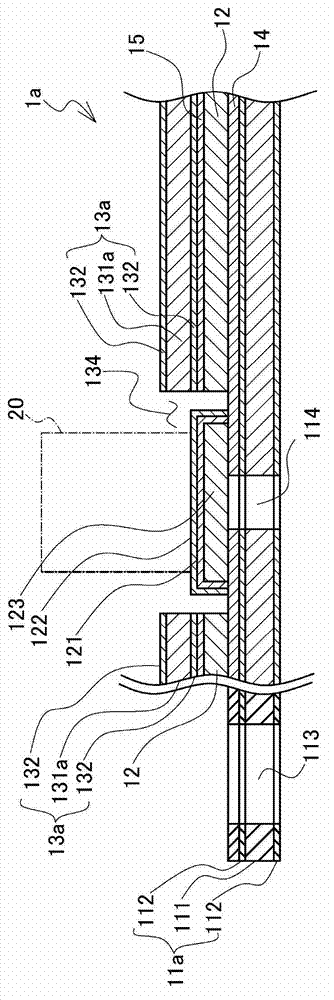

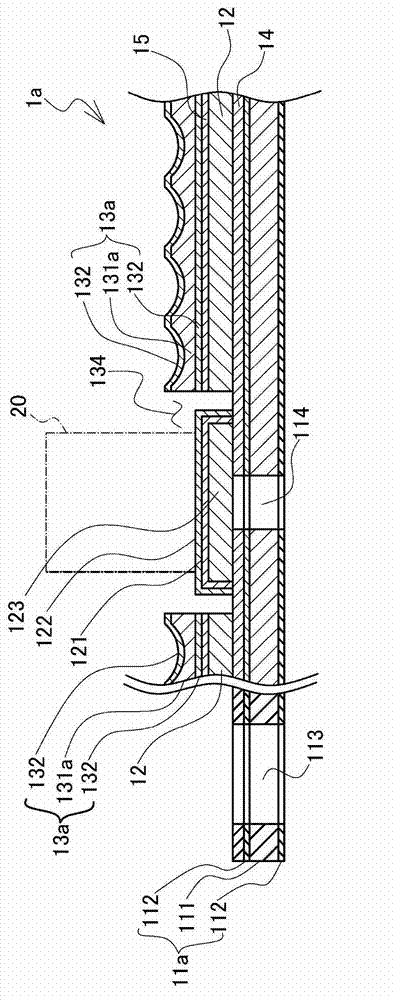

[0062] will refer to Figure 2A with 2B A flexible printed circuit 1a for mounting a light-emitting element according to a first embodiment of the present invention will be described. Figure 2A with 2B is a schematic sectional view showing the structure of the flexible printed circuit 1a for mounting a light emitting element according to the first embodiment of the present invention. Figure 2A shows a structure in which the surface of the cover film 13a has no irregularities, and Figure 2B It is shown that the surface of the cover film 13 has a concavo-convex structure.

[0063] Such as Figure 2A with 2B As shown, the base film 11a of the light emitting element mounting flexible printed circuit 1a according to the first embodiment has a laminated structure including a film substrate 111 and a protective film 112 formed on the surface of the substrate 111. The substrate 111 includes a metal material. For example, the substrate 111 is an aluminum film with a thickness...

no. 2 example

[0073] Next, refer to Figure 3A with 3B A flexible printed circuit 1b for mounting a light-emitting element according to a second embodiment of the present invention will be described. The same components as those of the light emitting element mounting flexible printed circuit 1a according to the first embodiment are denoted by the same reference numerals, and explanations for these components may be omitted. Figure 3A with 3B is a schematic sectional view showing the structure of a light emitting element mounting flexible printed circuit 1 b according to a second embodiment of the present invention. Figure 3A shows a structure in which the surface of the reflective film 16 has no unevenness, and Figure 3B It is shown that the surface of the reflective film 16 has a concavo-convex structure.

[0074] Such as Figure 3A with 3B As shown, the base film 11a, the wiring pattern 12, and the cover film 13a are the same as those in the case of the flexible printed circuit 1...

no. 3 example

[0083] Next, refer to Figure 4 A flexible printed circuit 1c for mounting a light-emitting element according to a third embodiment of the present invention will be described. Figure 4 A schematic sectional view showing the structure of a light emitting element mounting flexible printed circuit 1c according to a third embodiment of the present invention.

[0084] The base film 11a and the wiring pattern 12 of the flexible printed circuit 1c for mounting a light emitting element according to the third embodiment are the same as those in the flexible printed circuit 1a for mounting a light emitting element according to the first embodiment. Therefore, explanations for both are omitted.

[0085] A cover film 13 b is formed on the surface of the wiring pattern 12 . The cover film 13b includes a substrate 131b formed of a film made of a resin material and a substantially white reflective film 133 formed on the surface of the substrate 131b. For example, the substrate 131b may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com