Apparatus for improving absorption rate and emission rate in infrared heat wave nondestructive detection

A non-destructive testing, infrared thermal wave technology, applied in material defect testing and other directions, can solve problems such as damage, pollution, limit the application of infrared thermal wave non-destructive testing technology, etc., to improve the absorption rate and infrared emissivity, and improve the detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

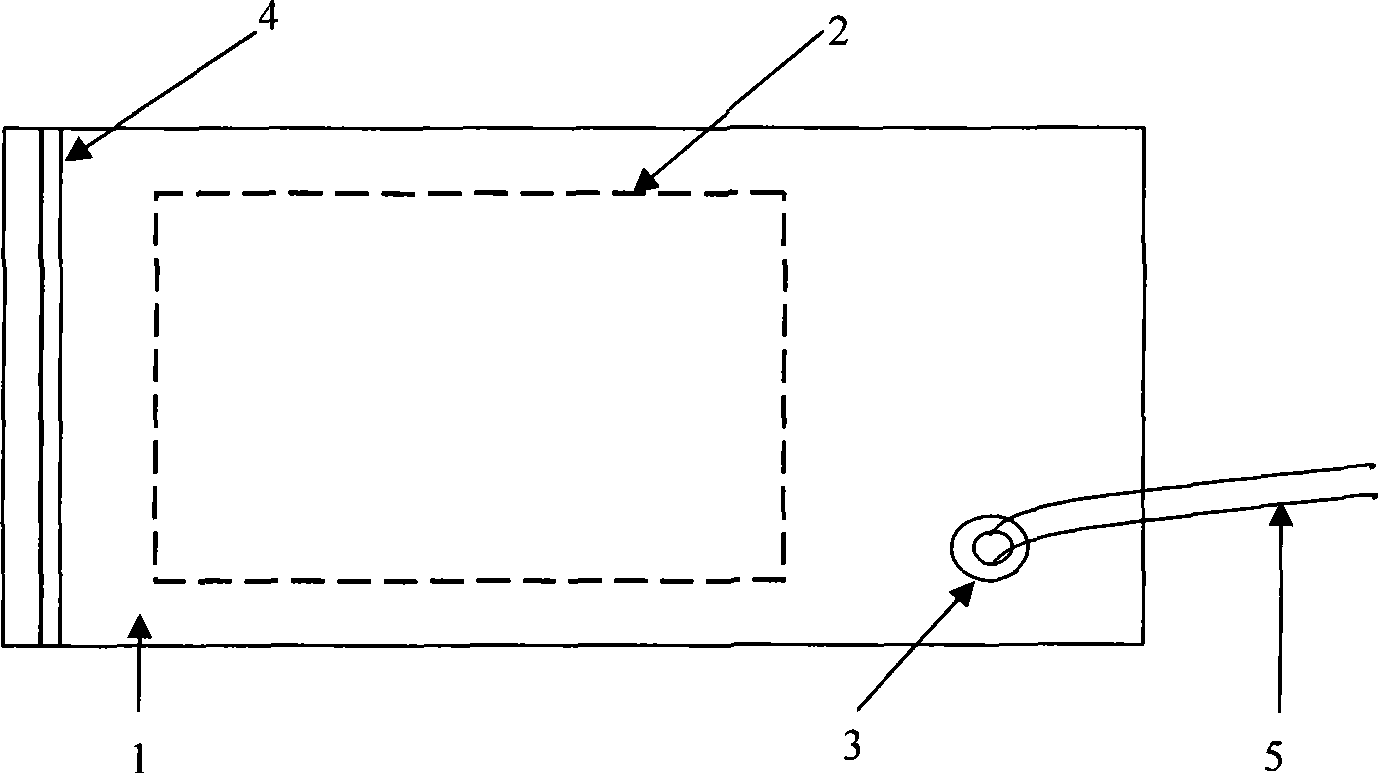

[0018] Example 1: For a vacuum coating device independent of the detection system, see figure 1 Firstly, the vacuum bag 1 of suitable material should be selected, and the material of the vacuum bag 1 is required to be a polymer film with high elasticity and high tensile strength, which has good visible light absorption rate and infrared emission rate. Put the detected object 2 into the vacuum bag 1 and seal the vacuum bag 1 with the buckle 4, pump out the air in the vacuum bag 1 through the air hole 3, so that there is no air gap between the film of the vacuum bag 1 and the detected object 2 In close contact, the air hole 3 is connected to the vacuum device through the air pipe 5 . To further increase the visible light absorption rate and infrared emission rate of the film surface, uniform spraying treatment can be carried out on the film surface.

Embodiment 2

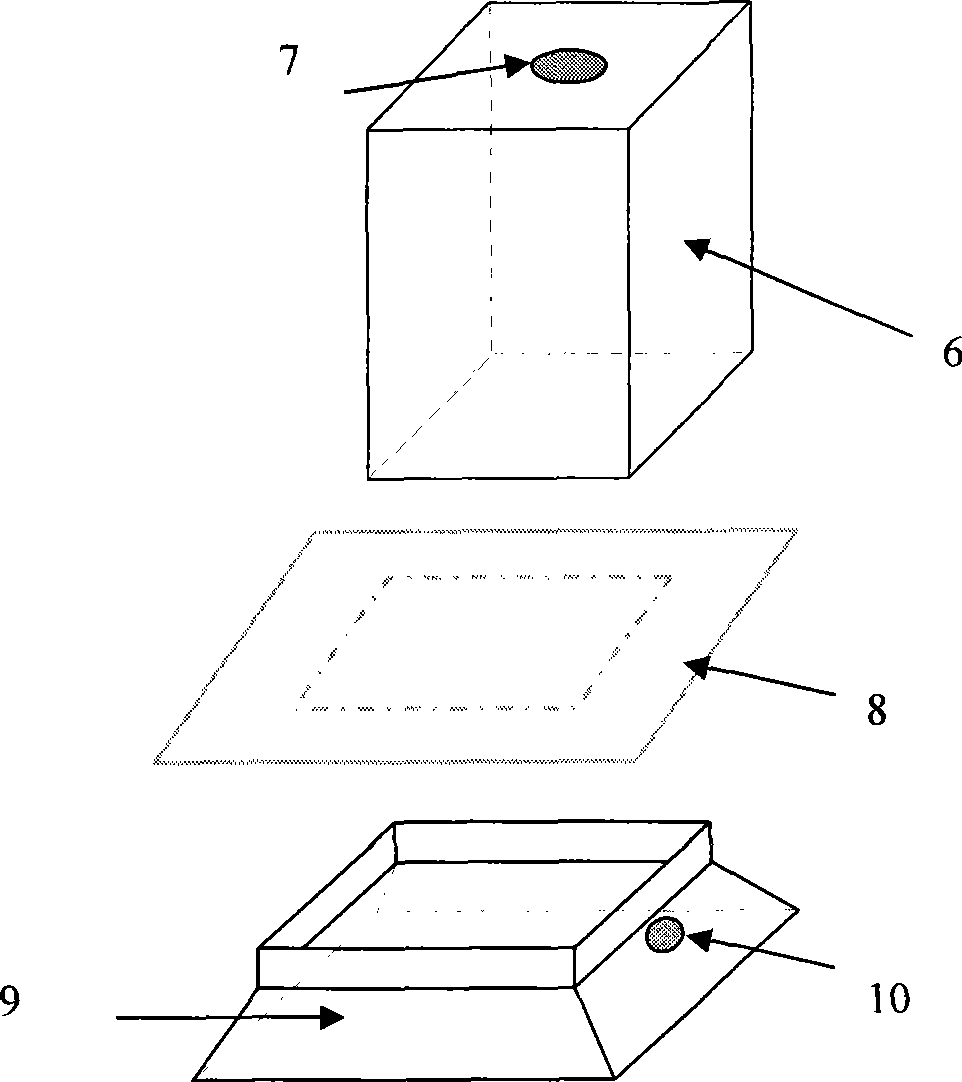

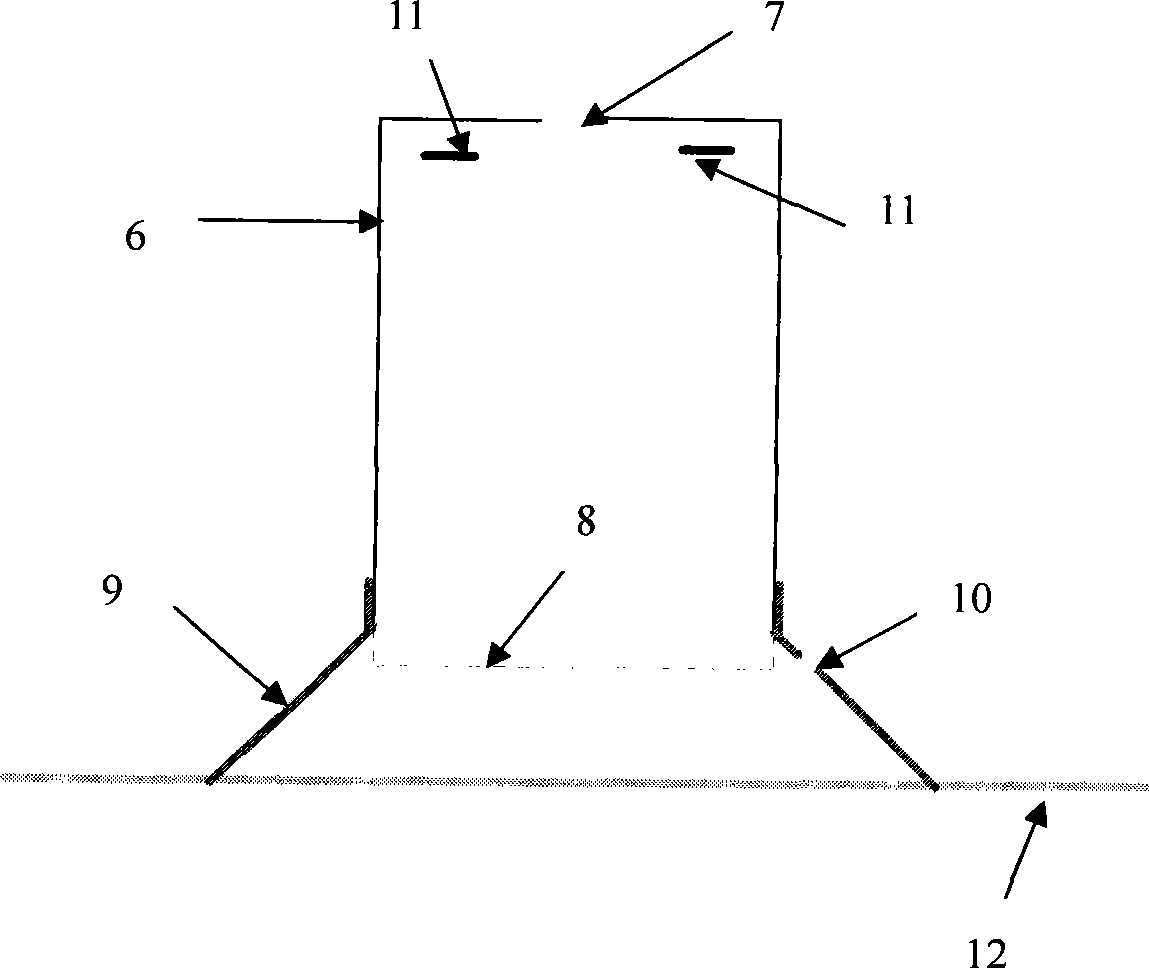

[0019] Example 2: The vacuum coating device in the infrared thermal wave non-destructive testing system see figure 2 and image 3 . Add a rubber skirt 9 between the flashlight cover 6 and the surface 12 of the object to be measured. The rubber material used to make the rubber skirt 9 should have certain elasticity. The shape and size of the upper port of the rubber skirt 9 are the same as those of the flashlight cover 6. The shape and size of the port match, and the shape and radian of the port under the rubber skirt 9 need to be designed according to the shape and surface radian of the test piece. Have air-breathing hole 10 on rubber skirt circumference 9. Cover the upper port of the rubber skirt 9 with the film 8, then insert the lower port of the flash cover 6 into the upper port of the rubber skirt 9, and at the same time clamp the film 8, during the measurement, the lower port of the rubber skirt 9 Place it on the surface 12 of the measured object, so that a closed sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com