Printed circuit board heat exchanger channel flow field visualization device

A technology for printed circuit boards and heat exchangers, applied in the field of flow field visualization devices for the channels of printed circuit board heat exchangers, which can solve problems such as inability to visualize flow field information in channels, and achieve good water following performance and high surface reflectivity , the effect of close density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

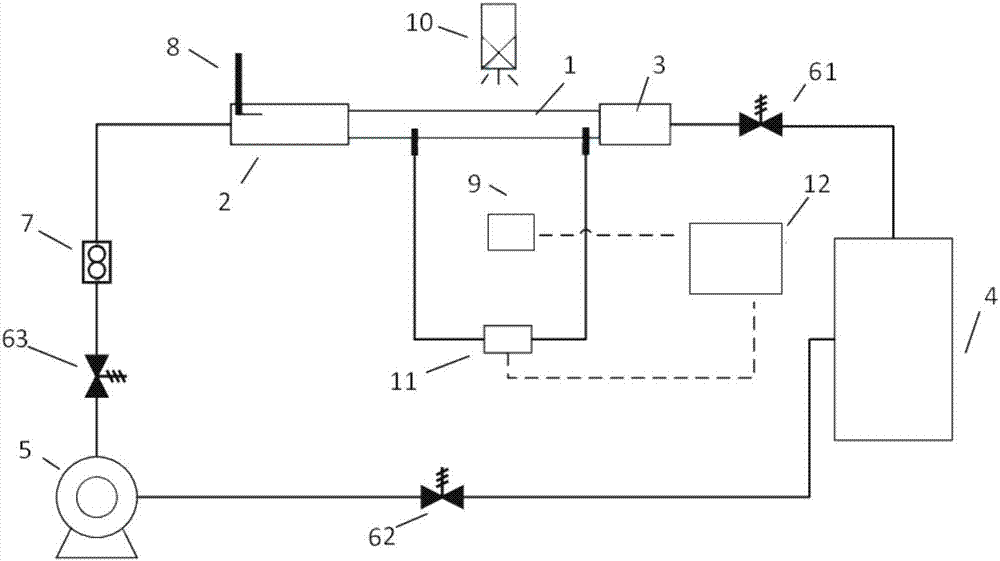

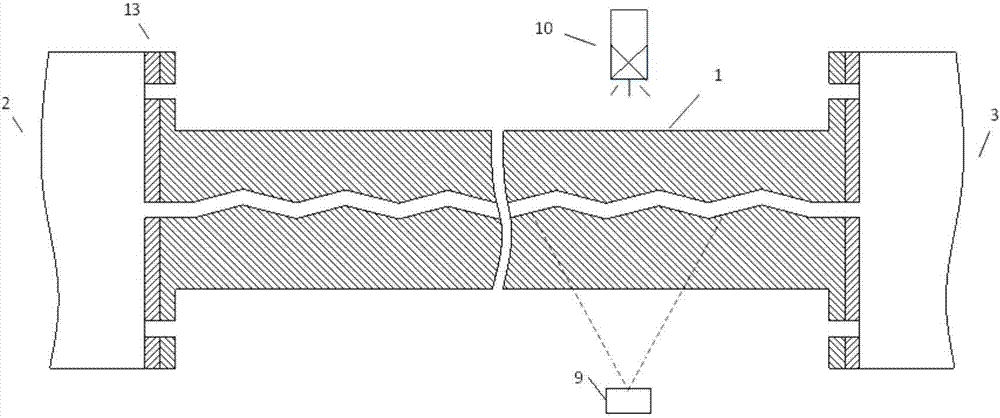

[0026] refer to figure 1 and figure 2 , the printed circuit board heat exchanger channel flow field visualization device of the present invention includes a water tank 4, a tracer particle injector 8, a front water collection pipe 2, a PCHE visualization channel module 1, a rear water collection pipe 3, a light source 10, a CCD camera 9, Computer 12 and differential pressure measurement system 11 for detecting the pressure drop resistance information of the water before and after the channel in the PCHE visualization channel module 1;

[0027] The outlet of the tracer particle injector 8 is connected with the tracer particle inlet of the front water collection pipe 2, the water outlet of the water tank 4 is connected with the water inlet of the front water collection pipe 2, and the water outlet of the front water collection pipe 2 is connected with the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com