White-light LED light source with sterilization effect and manufacturing method thereof

A technology of LED light source and manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven irradiation, weak UV resistance, inconvenient production and manufacturing, etc., and achieves improved UV resistance and good UV resistance. , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

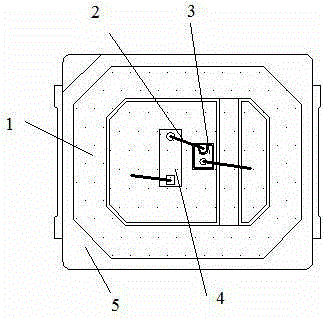

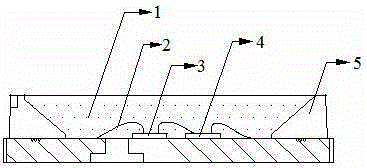

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0025] Such as figure 1 Shown is the top view of the filling figure after the fluorescent glue of the present invention is mixed, figure 2 It is a section view of the filled figure after mixing the fluorescent glue of the present invention. A white light LED light source with bactericidal effect, including PCT support 5 with heat sink, UV chip 3, blue light chip 4, gold wire 2 and fluorescent glue 1; wherein, the UV chip and blue light chip are fixed on the PCT support Inside, the UV chip and the blue chip are connected through gold wire welding, and the fluorescent glue is coated in the PCT bracket and covered on the UV chip and the blue chip.

[0026] The fluorescent glue is prepared by uniformly mixing potting silica gel and fluorescent powder in proportion.

[0027] The potting silica gel is UV-resistant potting silica gel.

[0028] The em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com