Multilayer optical recording medium and optical recording method

An optical recording medium, optical recording technology, applied to optical recording media, optical recording/reproduction, data recording, etc., can solve the problem of not explaining the protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 21 and comparative example 1 to 5

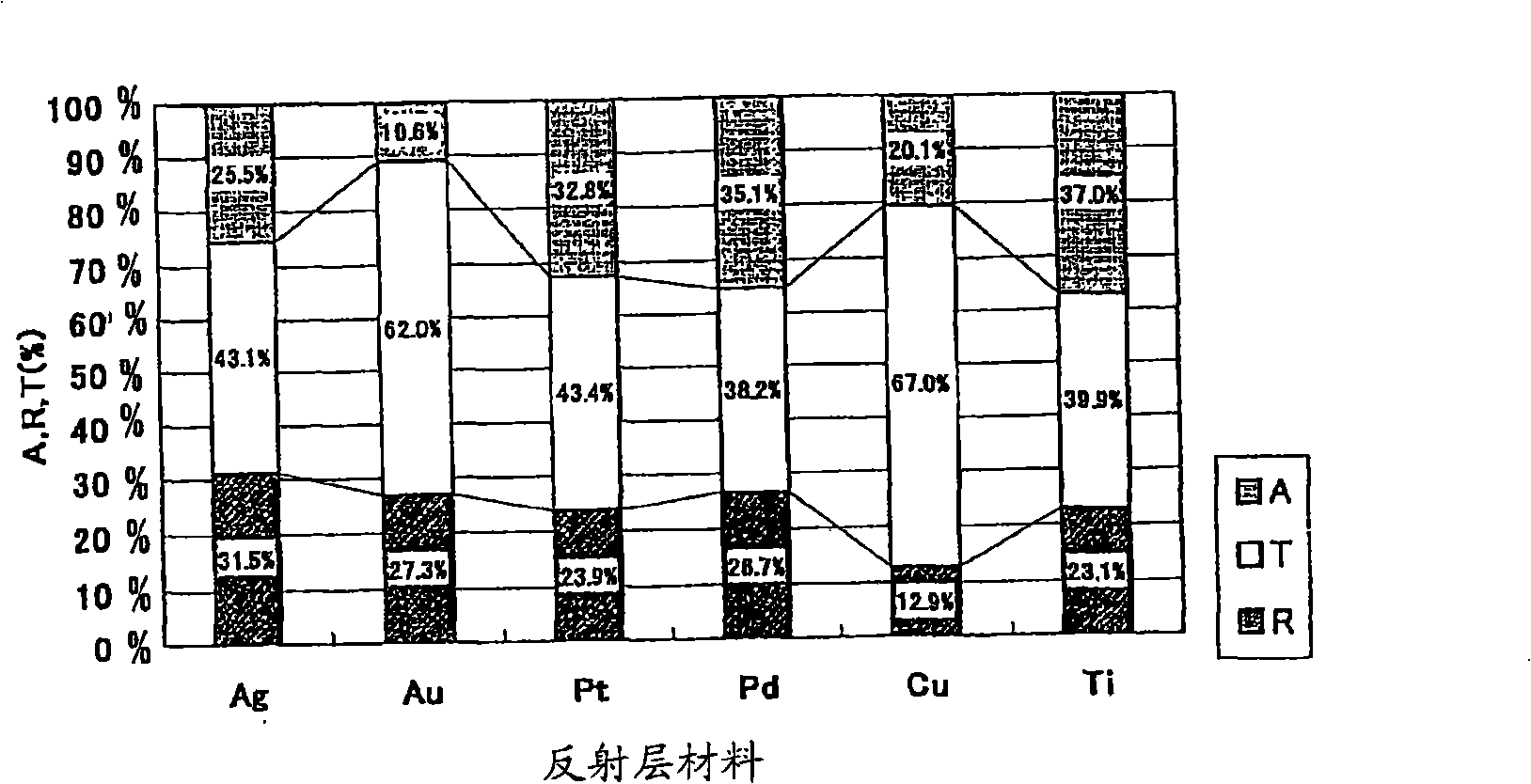

[0136] The recording linear velocity at the time of recording in the first recording layer was 9.2 m / s. Random recording was repeated 10 times (DOW 10) on three tracks, and the middle track among them was reproduced. Random records refer to marks and spaces in irregular records 3T to 11T and 14T1010.

[0137] In the evaluation criteria, the recording power in which the light transmittance in the first information layer is 40% or more and the degree of modulation is saturated is the optimum recording power Ppo [mW], when recording in the first information layer by Ppo The degree of modulation of is M (DOW 10), and the reflectance of the crystal after recording is Itop (DOW 10). A case of “M≧0.55 and Itop×X≧4.0%” was determined as A, a case of “M≧0.55 and 4.0%<Itop≧3.5%” was determined as B, and cases other than these cases were determined as C.

[0138] The evaluation results are collectively shown in Table 2.

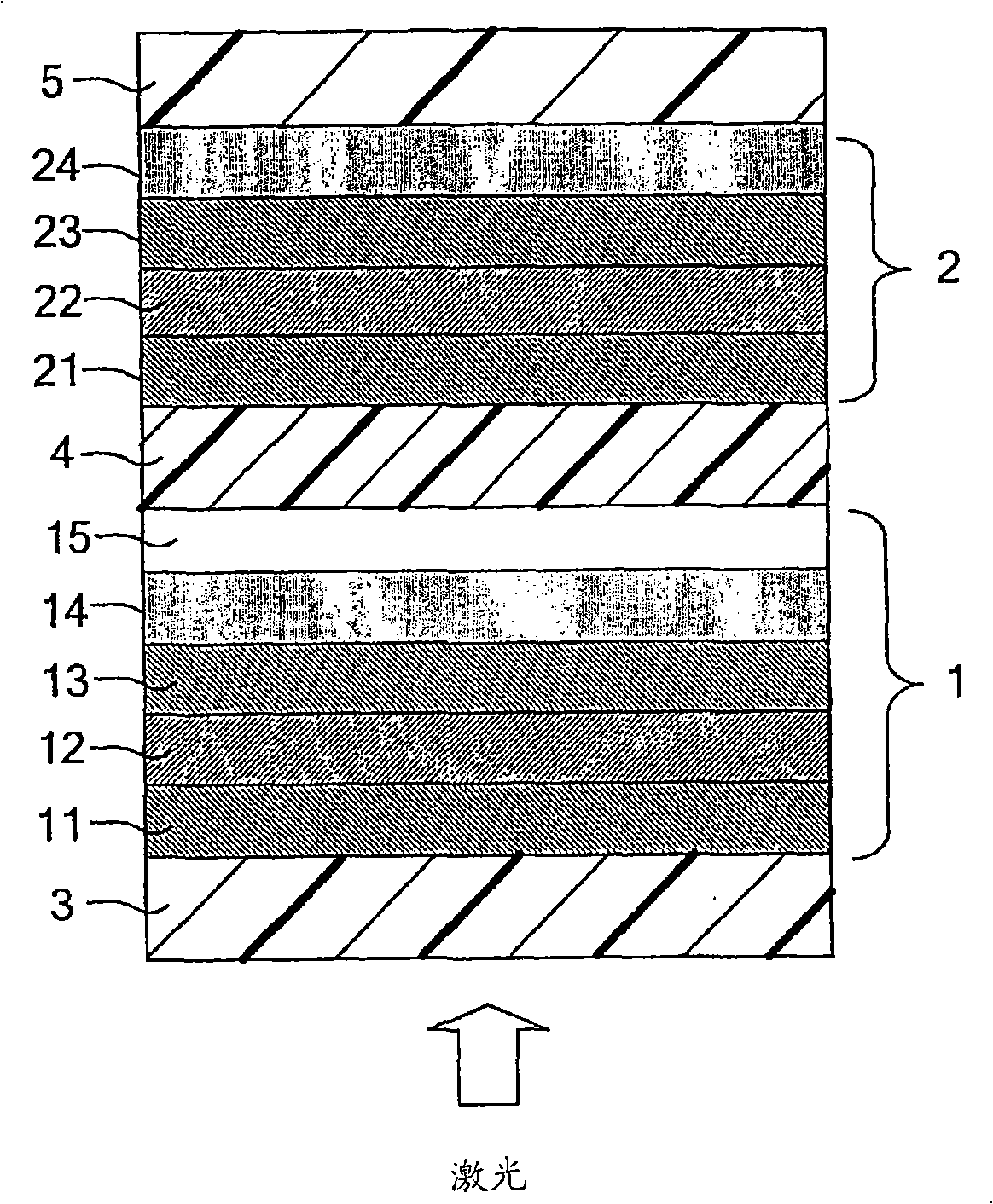

Embodiment 1

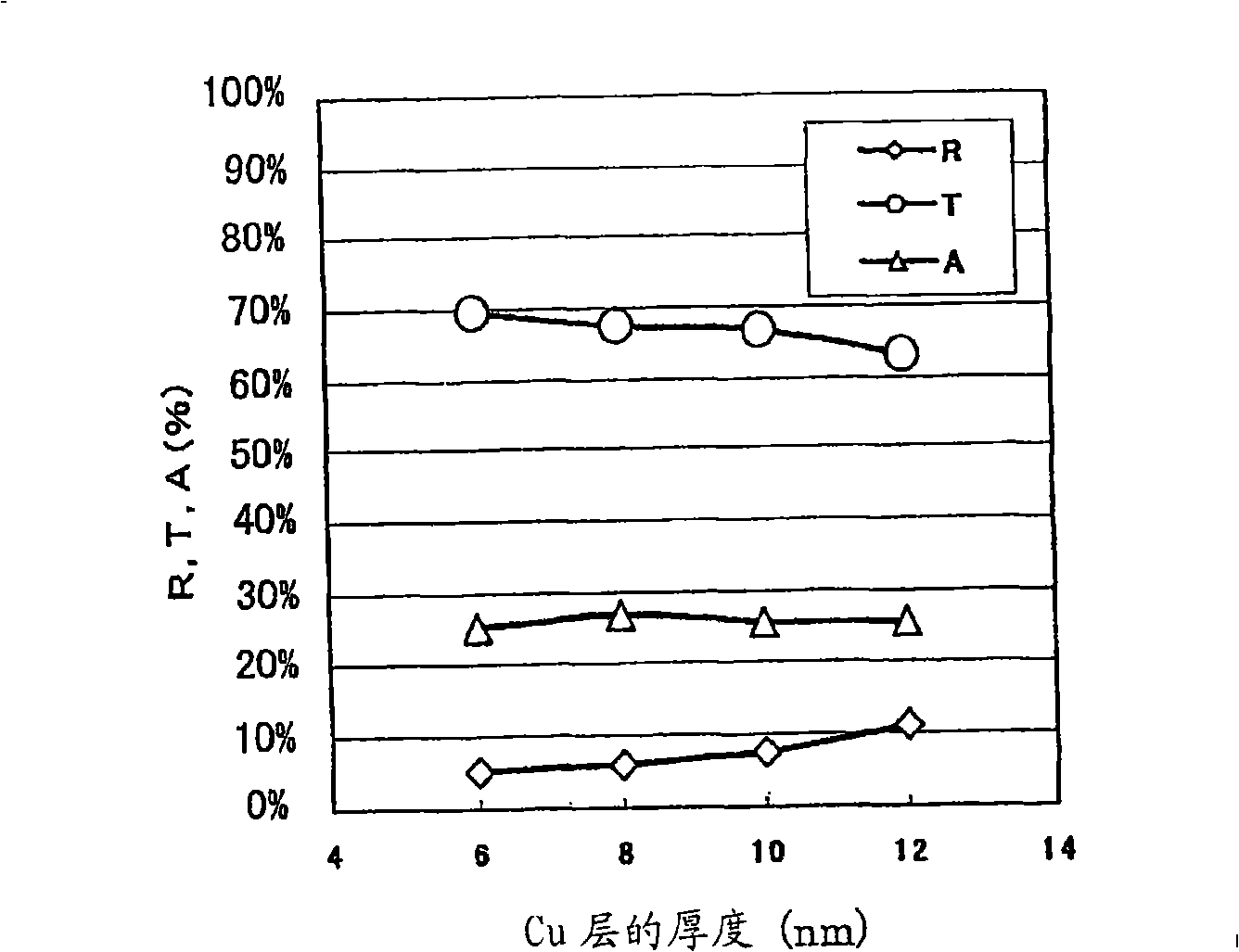

[0140] ZnS (80 mol %)-SiO with a thickness of 60 nm was sequentially formed on a first substrate made of polycarbonate resin with a diameter of 12 cm and a thickness of 0.58 mm in an Ar atmosphere by a sputtering method. 2 (20mol%) constitutes the first lower protective layer, the thickness is 7.6nm by Ag 0.2 In 3.5 Sb 69.2 Te 21.1 Ge 6 The first recording layer composed of In with a thickness of 5nm 2 o 3 (7.5mol%)-ZnO(22.5mol%)-SnO 2 (60mol%)-Ta 2 o 5 (10mol%) of the first upper protective layer, a thickness of 8nm, the first reflective layer made of a material in which 1.1% by mass of Mo is added to Cu, and a thickness of 80nm of In 2 o 3 (7.5mol%)-ZnO(22.5mol%)-SnO 2 (60mol%)-Ta 2 o 5 (10mol%) to form a first information layer, wherein the first substrate has on one side a tracking guide asperity formed by continuous grooves with a track pitch of 0.74um.

[0141] By adopting the same substrate as the first substrate as the second substrate, a second reflective...

Embodiment 2

[0145] A two-layer phase-change optical recording medium was fabricated in the same manner as in Example 1, except that the thickness of the light-transmitting layer in the first information layer was changed to 60 nm in Example 1. The light transmittance in the first information layer after initialization was 43.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com